- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

More Language

Untranslated

فروری . 14, 2025 14:33

Back to list

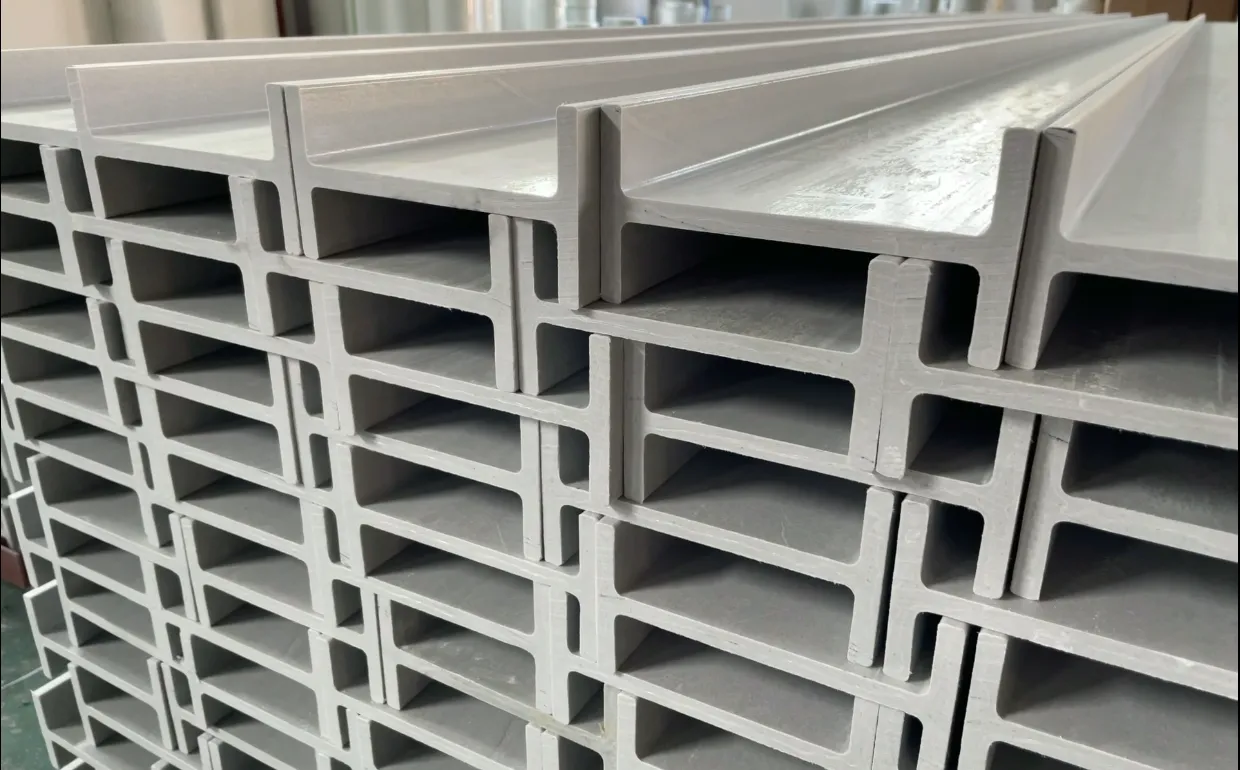

frp profiles

Fiber Reinforced Plastic (FRP) profiles have emerged as a revolutionary material in various industries, offering unparalleled benefits that cater to the needs of modern engineering and design. These composite materials are engineered by combining a polymer matrix reinforced with fibers, typically glass, carbon, or aramid, which result in a lightweight, yet immensely strong and durable product. The versatility and adaptability of FRP profiles have transformed how industries approach lightweight structural solutions, presenting them as an ideal choice for applications where traditional materials fall short.

Quality assurance is another critical factor bolstering the trust in FRP profiles. Manufacturing processes involve stringent oversight, with modern techniques ensuring consistent product quality. Manufacturers often collaborate with industry-specific regulatory bodies to ensure that FRP profiles meet all necessary health, safety, and performance standards, solidifying their reputation as a trustworthy solution in critical applications. The sustainable aspect of FRP profiles cannot be overlooked. As industries worldwide pivot towards eco-friendly practices, FRP profiles stand out due to their long lifecycle and low maintenance requirements. Additionally, advancements in recycling technologies are paving the way for FRP profiles to be more environmentally friendly, reducing waste, and contributing to the circular economy. In summary, FRP profiles represent a significant advancement in material science, offering robust solutions across various industries. Their combination of lightweight nature, high strength, customizability, and sustainability makes them an attractive option for engineers and designers globally. By continuing to expand their use and capabilities, FRP profiles are set to redefine the standards of innovation and reliability in product engineering and design, ensuring their place in the forefront of next-generation materials.

Quality assurance is another critical factor bolstering the trust in FRP profiles. Manufacturing processes involve stringent oversight, with modern techniques ensuring consistent product quality. Manufacturers often collaborate with industry-specific regulatory bodies to ensure that FRP profiles meet all necessary health, safety, and performance standards, solidifying their reputation as a trustworthy solution in critical applications. The sustainable aspect of FRP profiles cannot be overlooked. As industries worldwide pivot towards eco-friendly practices, FRP profiles stand out due to their long lifecycle and low maintenance requirements. Additionally, advancements in recycling technologies are paving the way for FRP profiles to be more environmentally friendly, reducing waste, and contributing to the circular economy. In summary, FRP profiles represent a significant advancement in material science, offering robust solutions across various industries. Their combination of lightweight nature, high strength, customizability, and sustainability makes them an attractive option for engineers and designers globally. By continuing to expand their use and capabilities, FRP profiles are set to redefine the standards of innovation and reliability in product engineering and design, ensuring their place in the forefront of next-generation materials.

Share

Next:

Latest news

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025