لوڈ ہو رہا ہے...

- نمبر 9، Xingyuan South Street، Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- ہماری ویب سائٹ ملاحظہ کرنے میں خوش آمدید!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- انگریزی

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

FRP Square Tube: The New Industry Standard for Chemical and Structural Applications

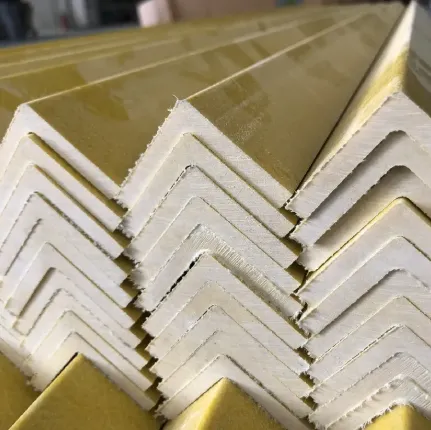

When it comes to durable, corrosion-resistant, and lightweight structural solutions, the frp square tube stands as a superior alternative to traditional piping and tubing systems. Whether used in the chemical industry, structural framing, or corrosive environments, frp square tube products offer unmatched performance, especially in places where traditional metal fails.

What Are the Main Components of FRP Square Tubes?

The excellent performance of a frp square tube is rooted in its carefully engineered composition. These tubes are made from high-strength fiberglass reinforcements embedded in a thermosetting resin matrix. The combination of these two materials results in a composite product with unique properties: high mechanical strength, outstanding corrosion resistance, and dimensional stability.

The fiberglass acts as the structural skeleton, providing the necessary tensile and flexural strength. The resin—often polyester, vinyl ester, or epoxy—serves as the matrix, binding the fibers together while adding chemical resistance, UV resistance, and surface finish. In most industrial-grade frp square pipe designs, additional surface veils are applied to enhance resistance to environmental degradation and to maintain a smooth outer layer.

These structural characteristics make the frp square tube far more than just a plastic pipe—it’s a high-performance engineered solution that outperforms metals in demanding environments.

FRP Square Tubes vs. Traditional Metal Pipes: A Performance Comparison

Comparing a frp square tube with conventional metal piping like steel or aluminum reveals several key advantages. First and foremost is corrosion resistance. In environments exposed to salt, chemicals, acids, or alkalis, metals corrode and lose strength rapidly. In contrast, the frp square pipe retains its integrity even after prolonged exposure to aggressive substances.

Another major benefit is weight. FRP square tube products are significantly lighter than steel or aluminum, reducing transportation and installation costs. Their low weight also means that support structures can be simplified, reducing the overall system cost.

Electrically, the frp square pipe is non-conductive, which is an essential feature in electrical substations, power plants, and chemical facilities. Unlike metal, which requires grounding and insulation measures, frp square tube systems are naturally safe in electrical applications.

From a maintenance perspective, frp square tube structures demand little to no upkeep. They don't rust, crack, or require repainting. This contributes to a more attractive total lifecycle cost, even if the initial frp square tube price is slightly higher than basic steel. Over a 20–30 year period, the return on investment is clearly in favor of FRP.

Applications of FRP Square Tubes in the Chemical Industry

The chemical industry, with its exposure to highly corrosive substances and extreme environments, demands materials that can survive where metal and wood fail. This is precisely where the frp square tube proves its worth.

In chemical processing plants, frp square pipe structures are used for equipment supports, platforms, handrails, walkways, tank bracing, and ventilation frameworks. Their chemical resistance ensures they remain unaffected by acids, chlorine compounds, or caustic solutions. More importantly, they maintain mechanical stability even after years of exposure.

Additionally, frp square tube systems are commonly found in fume hoods, exhaust systems, and fluid transport networks. Their non-metallic composition makes them compatible with sensitive environments where contamination or chemical reactivity must be avoided.

Maintenance downtime in chemical plants is costly. By switching to frp square pipe, facility managers reduce the risk of component failure and extend the time between shutdowns. The minimal maintenance and high durability make it the most logical material choice for critical applications.

Cost-Efficiency and Long-Term Value of FRP Square Tube Systems

When evaluating materials, cost is always a factor—and the frp square tube price offers excellent value when long-term durability and performance are considered. While the initial frp square tube price may be slightly above that of basic steel tubes, it includes significant advantages that translate into financial savings over time.

For instance, there's no need for painting, galvanizing, or corrosion protection. Installation is easier and faster due to the lighter weight. And since the frp square pipe is resistant to UV, chemicals, and temperature fluctuations, its lifespan often exceeds 20 years with minimal degradation.

Additionally, the frp square tube can be customized to meet different color specifications, fire-retardant requirements, and mechanical strength needs. Whether you’re building for marine environments, food processing facilities, or acid storage sites, frp square tube systems can be engineered to exceed the exact specifications of your project—without inflating your budget.

With modern production techniques and competition among frp square tube suppliers, the current frp square tube price is more attractive than ever, especially when bulk or project-based pricing is factored in.

FRP Square Tube FAQs

What materials are used in a frp square tube?

A frp square tube is made from high-strength fiberglass reinforcements and thermosetting resins, such as polyester or vinyl ester. This combination creates a durable, corrosion-resistant composite structure.

How does frp square pipe compare to steel pipe?

FRP square pipe is lighter, corrosion-resistant, non-conductive, and requires far less maintenance than steel. It performs better in chemical, marine, and outdoor environments where metal would deteriorate.

What are the typical uses of frp square tube in the chemical industry?

FRP square tube is used in chemical plants for equipment supports, walkways, platforms, railings, and pipe bracing due to its excellent chemical resistance and mechanical strength.

Is the frp square tube price competitive with other materials?

Yes. While the upfront frp square tube price may be slightly higher, the long-term savings in maintenance, replacement, and labor costs make it far more cost-effective than metals over time.

Can frp square pipe be customized for specific applications?

Absolutely. FRP square pipe can be manufactured with custom colors, fire-retardant properties, specific mechanical strength, and different surface finishes to meet any industry requirement.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingخبریںNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersخبریںNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessخبریںNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesخبریںNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectخبریںNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesخبریںNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingخبریںNov.11,2025