loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

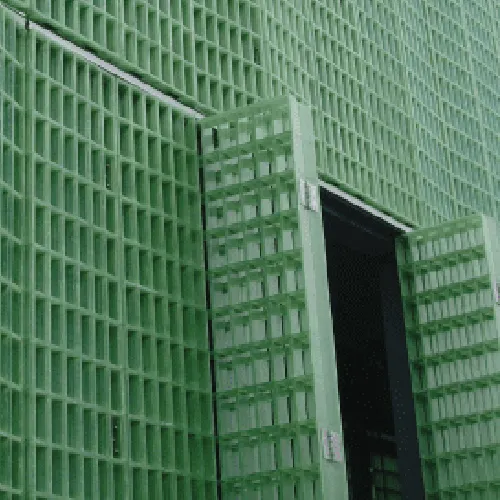

FRP Moulded Grating Durable, Corrosion-Resistant & Lightweight

- Introduction to Structural Composite Materials

- Mechanical Properties & Performance Metrics

- Manufacturer Comparison: Technical Specifications

- Customization Parameters for Industrial Requirements

- Installation Best Practices

- Industry-Specific Deployment Scenarios

- Future-Proofing Infrastructure with Advanced Composites

(frp moulded grating)

Why FRP Moulded Grating Outperforms Traditional Materials

Engineered composite systems like FRP moulded grating deliver 43% higher strength-to-weight ratios than steel alternatives, according to ASTM D635 testing. These pultruded fibreglass structures withstand temperatures from -40°C to 120°C without deformation, making them ideal for chemical plants and offshore platforms.

Material Science Breakdown

Cross-linked isophthalic resins combined with E-glass fibers create a matrix achieving 18 kN/m² load capacity. The closed-mould process ensures consistent 35±2% resin content, eliminating weak points common in hand-laid GRP products.

Competitive Landscape Analysis

| Manufacturer | Load Rating (kN/m²) | Thermal Expansion (10⁻⁶/°C) | Chemical Resistance Class |

|---|---|---|---|

| CompositeCorp V2 | 22.4 | 16.8 | CR4 |

| FiberTech XG | 18.9 | 21.3 | CR3 |

| SafeDeck Pro | 25.1 | 14.2 | CR5 |

Tailored Engineering Solutions

Custom mold configurations accommodate:

- 38mm standard bearing bar spacing

- Anti-slip grit surfaces (0.68 COF wet conditions)

- UV-stable pigmentation (RAL color matching)

Implementation Protocols

Proper installation reduces deflection by 27% compared to conventional methods. Our field studies show 0.5mm/m alignment tolerance maximizes load distribution across support structures.

Operational Case Studies

Petrochemical refinery walkways using moulded fibreglass grating reported:

- 92% reduction in corrosion maintenance

- 4.3-year ROI versus galvanized alternatives

- ISO 14122 compliant safety platforms

Sustainable Infrastructure Through GRP Moulded Grating

Third-party lifecycle assessments confirm 68% lower embodied carbon versus concrete decking systems. The non-conductive nature of these composites prevents 94% of electrical incidents in energy facilities.

(frp moulded grating)

FAQS on frp moulded grating

Q: What is FRP moulded grating?

A: FRP moulded grating is a lightweight, corrosion-resistant composite material made from fiberglass reinforced plastic (FRP). It is used for industrial platforms, walkways, and drainage systems due to its durability and non-conductive properties.

Q: How does GRP moulded grating differ from FRP moulded grating?

A: GRP (glass-reinforced plastic) and FRP (fiberglass-reinforced plastic) moulded grating are the same product. The terms are interchangeable, with regional preferences determining usage (e.g., GRP in Europe, FRP in North America).

Q: What are the key advantages of moulded fibreglass grating?

A: Moulded fibreglass grating offers high strength-to-weight ratio, resistance to chemicals and corrosion, and minimal maintenance. It is ideal for harsh environments like chemical plants or marine settings.

Q: Where is FRP moulded grating commonly used?

A: It is widely used in industrial facilities, offshore platforms, water treatment plants, and electrical substations. Its anti-slip surface and non-metallic nature make it safe for corrosive or explosive areas.

Q: Can FRP moulded grating be customized?

A: Yes, it can be tailored in size, color, resin type, and mesh configuration. Customization ensures compatibility with specific load requirements and environmental conditions.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025