loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 10, 2025 12:34

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

FRP pressure vessel filters represent a significant advancement in water treatment technology, offering unparalleled benefits for various industries needing robust and efficient filtration systems. These filters, primarily constructed from fiberglass reinforced plastic, are ideal for processes requiring high durability, resistance to corrosion, and the sustainability of performance under demanding conditions.

In terms of expertise, the installation and operational instruction of FRP pressure vessel filters are backed by extensive research and development, conducted by leading manufacturers in the filtration industry. This commitment to engineering excellence ensures that end-users receive a product that is not only engineered for optimal performance but also supported by detailed implementation guides and responsive customer service. Training sessions and workshops often provided by the manufacturers further deepen the user’s understanding, allowing for efficient and effective deployment of these vessels in various sectors. The environmental and economic benefits of utilizing FRP pressure vessel filters cannot be overstated. From an environmental perspective, the longevity and recyclability of FRP materials contribute to reduced waste and lower carbon footprints for companies. Economically, the reduced need for frequent replacements and decreased operational downtime translate into substantial cost savings over the lifetime of the system. Users have noted a swift return on investment due to the combination of decreased maintenance costs and increased process efficiency. The authoritative stance of FRP pressure vessel filters within the sector is solidified by extensive certifications and compliance with international standards, which assure stakeholders of their quality and reliability. Trusted by professionals globally, the adoption of FRP technology is not merely a trend but a shift towards more resilient and trustworthy filtration solutions. By integrating FRP pressure vessel filters into their operations, businesses leverage an advanced purification technology that encompasses the ideals of robustness, adaptability, and sustainability. It's a strategic investment that aligns with modern demands for eco-friendly and efficient water treatment systems, setting a precedent for future innovations in the filtration industry. This commitment to high-performance and sustainable solutions positions FRP pressure vessel filters as a cornerstone of industrial water treatment practices, offering tangible benefits and setting the benchmark for future developments in water purification technology.

In terms of expertise, the installation and operational instruction of FRP pressure vessel filters are backed by extensive research and development, conducted by leading manufacturers in the filtration industry. This commitment to engineering excellence ensures that end-users receive a product that is not only engineered for optimal performance but also supported by detailed implementation guides and responsive customer service. Training sessions and workshops often provided by the manufacturers further deepen the user’s understanding, allowing for efficient and effective deployment of these vessels in various sectors. The environmental and economic benefits of utilizing FRP pressure vessel filters cannot be overstated. From an environmental perspective, the longevity and recyclability of FRP materials contribute to reduced waste and lower carbon footprints for companies. Economically, the reduced need for frequent replacements and decreased operational downtime translate into substantial cost savings over the lifetime of the system. Users have noted a swift return on investment due to the combination of decreased maintenance costs and increased process efficiency. The authoritative stance of FRP pressure vessel filters within the sector is solidified by extensive certifications and compliance with international standards, which assure stakeholders of their quality and reliability. Trusted by professionals globally, the adoption of FRP technology is not merely a trend but a shift towards more resilient and trustworthy filtration solutions. By integrating FRP pressure vessel filters into their operations, businesses leverage an advanced purification technology that encompasses the ideals of robustness, adaptability, and sustainability. It's a strategic investment that aligns with modern demands for eco-friendly and efficient water treatment systems, setting a precedent for future innovations in the filtration industry. This commitment to high-performance and sustainable solutions positions FRP pressure vessel filters as a cornerstone of industrial water treatment practices, offering tangible benefits and setting the benchmark for future developments in water purification technology.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

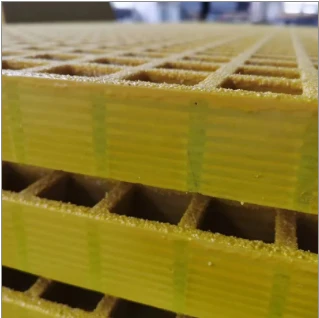

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025