naglo-load...

- 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Maligayang pagdating sa pagbisita sa aming website!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Ingles

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

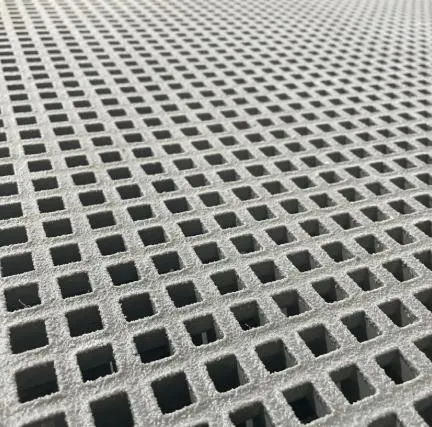

FRP Mini Mesh Grating: The Safer, Smarter Flooring Solution

As industries evolve and safety becomes a priority in infrastructure and design, materials like FRP mini mesh grating are revolutionizing how we think about non-slip surfaces and corrosion resistance. Offering a lightweight yet highly durable alternative to steel or wood, mini mesh grating is the ideal choice for environments where drainage, slip resistance, and minimal opening sizes are essential.

Whether you're outfitting a chemical plant, pedestrian walkway, or rooftop platform, FRP mini mesh, also known as GRP mini mesh grating, delivers strength, longevity, and superior safety in one cost-effective solution.

What Is Mini Mesh Grating?

Mini mesh grating refers to fiberglass-reinforced plastic (FRP) or glass-reinforced plastic (GRP) grating panels with smaller mesh openings than standard grating. Typically featuring square holes smaller than 13 mm, this type of grating offers increased foot support and reduced risk of items falling through, making it ideal for high-footfall or public areas.

Key Benefits of FRP Mini Mesh Grating:

Enhanced anti-slip properties

High strength-to-weight ratio

Corrosion and UV resistance

Fire-retardant and non-conductive

Lightweight and easy to install

Safe for pedestrian and wheelchair traffic

These characteristics make FRP mini mesh grating especially useful in areas where safety, hygiene, and durability are essential—such as food production zones, rail platforms, and marine facilities.

Applications and Use Cases of FRP and GRP Mini Mesh

From commercial buildings to offshore oil rigs, FRP mini mesh and GRP mini mesh grating are used across a wide range of industries. Their design offers solutions to many challenges that traditional materials cannot overcome.

- GRP Mini Mesh Grating in Public Infrastructure

GRP mini mesh grating is commonly used in pedestrian walkways, overpasses, and access ramps. Its fine mesh ensures a solid walking surface with minimal gaps—ideal for high-heeled shoes, canes, and wheelchair casters. It also prevents objects such as keys or tools from falling through.

- FRP Mini Mesh in Chemical and Marine Environments

Thanks to its exceptional resistance to chemicals and saltwater, FRP mini mesh is perfect for platforms, docks, and walkways in harsh environments. It remains strong and slip-resistant even when exposed to moisture, oils, or corrosive agents.

- Mini Mesh Decking in Rooftops and Maintenance Platforms

Mini mesh decking is an excellent choice for rooftops or elevated platforms where drainage and foot safety are both priorities. It’s often used in HVAC service platforms, maintenance areas, and rooftop access zones, offering a firm yet permeable surface that won’t rust or degrade over time.

Why Choose FRP Mini Mesh Grating Over Traditional Materials?

When compared to steel, wood, or aluminum, FRP mini mesh grating delivers a combination of safety, performance, and low maintenance that’s hard to match.

Key Comparisons:

Corrosion Resistance: Unlike steel, FRP mini mesh grating doesn’t rust or require protective coatings.

Weight: It is significantly lighter than steel, reducing structural load and easing transportation and installation.

Slip Resistance: Textured surfaces and micro-mesh openings provide superior grip under wet or oily conditions.

Non-Conductive: Ideal for electrical or telecom facilities where safety from electrical hazards is essential.

Mababang Pagpapanatili: Requires no painting, sealing, or chemical treatment over time.

Furthermore, FRP mini mesh and mini mesh decking are available in various colors, including yellow, grey, and green, allowing for safety zoning and visual management in work areas.

In applications where strength, safety, and long-term performance are essential, FRP mini mesh grating, GRP mini mesh grating, and mini mesh decking stand out as practical, reliable, and future-ready choices. Whether you're installing walkways in a chemical plant or building rooftop platforms, these materials ensure that your infrastructure meets modern safety and durability standards.

Investing in FRP mini mesh is more than a design choice—it’s a commitment to safer, smarter, and more sustainable environments.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingBalitaNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersBalitaNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessBalitaNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesBalitaNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectBalitaNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesBalitaNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingBalitaNov.11,2025