loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Benefits of FRP Walkway Systems

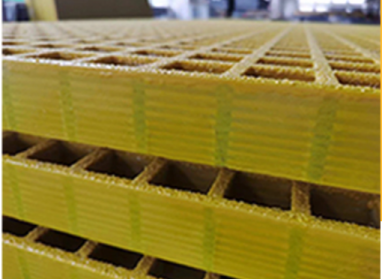

FRP walkway systems (Fiberglass Reinforced Plastic walkways) have become a game-changer for industries, commercial facilities, and public spaces—offering a unique blend of durability, safety, and cost-effectiveness that outperforms traditional materials like steel, wood, or concrete. Whether it’s a FRP walkway grating for industrial platforms, a walkway FRP for chemical plant catwalks, or a lightweight FRP path for outdoor parks, these systems address key pain points like corrosion, heavy maintenance, and safety hazards. Zhaojia Composites Co., Ltd (ZJ Composites), a leader in composite materials with a focus on quality and innovation, specializes in crafting high-performance FRP walkway solutions alongside FRP grating and profiles. Equipped with perfect testing equipment, strong technical support, and global export experience, ZJ Composites ensures their FRP walkway grating and walkway FRP products meet international standards, making them a trusted partner for wholesalers seeking reliable, long-lasting walkway systems. This article explores the core benefits of FRP walkway systems, highlighting why they’re the preferred choice for diverse applications and how ZJ Composites’ offerings elevate these advantages.

Corrosion Resistance of FRP Walkway Grating

- All-Environment Durability of FRP Walkway: FRP walkway systems excel in corrosive environments where steel rusts and wood rots—ZJ Composites’ FRP walkway grating is made from a fiberglass core embedded in a resin matrix (polyester or vinyl ester) that repels water, salt, chemicals, and humidity. Unlike steel walkways that require annual painting to prevent corrosion, walkway FRP retains its structural integrity for 20–30 years with minimal maintenance. For example, in coastal refineries or wastewater treatment plants, FRP walkway systems withstand saltwater spray and chemical spills without degradation— a key selling point for wholesalers serving clients in harsh industrial sectors.

- Chemical Resistance of FRP Walkway Grating: FRP walkway grating from ZJ Composites is resistant to a wide range of chemicals, including acids, alkalis, and solvents—critical for industries like pharmaceuticals, food processing, or chemical manufacturing. The resin matrix acts as a barrier, preventing chemicals from seeping into the fiberglass core and weakening the structure. Wholesalers can note that this resistance eliminates the need for costly chemical-resistant coatings (required for steel walkways) and reduces the risk of walkway failure due to chemical damage, ensuring long-term safety for end-users.

Lightweight and Easy Installation of Walkway FRP

- Lightweight Design of FRP Walkway: FRP walkway systems are 70% lighter than steel and 50% lighter than concrete, making them easy to transport, handle, and install—no heavy lifting equipment (like cranes) needed. ZJ Composites’ walkway FRP panels weigh just 8–12kg per square meter, so a 2-person team can carry and position panels quickly, even in tight spaces like industrial mezzanines or rooftop walkways. This lightweight nature also reduces stress on supporting structures, extending the life of existing beams or frames— a major advantage for wholesalers working on retrofitting projects.

- Simplified Installation of FRP Walkway Grating: FRP walkway grating from ZJ Composites is designed for hassle-free installation, with pre-drilled holes aligned to standard support spacing and interlocking edges for seamless panel connection. The company provides all necessary hardware (corrosion-resistant bolts, washers) and a detailed installation manual, so even teams with limited experience can complete projects in less time. For example, a 100sq. m FRP walkway installation takes 1–2 days with ZJ Composites’ products, compared to 3–4 days for steel grating— cutting labor costs by 40% for clients.

Safety Benefits of FRP Walkway Systems

|

Safety Hazard |

How FRP Walkway Systems Address It |

Key Product Feature |

ZJ Composites Advantage |

|

Slip-and-Fall Accidents |

FRP walkway grating has a non-slip surface (textured resin or grit). |

Molded-in anti-slip texture (meets OSHA standards). |

Texture retains grip even when wet/oily. |

|

Electrical Conductivity |

Walkway FRP is non-conductive, preventing electric shocks. |

Fiberglass core + non-metallic resin matrix. |

Tested to 10,000V—safe for electrical substations. |

|

Fire Risks |

Flame-retardant FRP walkway (optional) slows fire spread. |

Vinyl ester resin with fire-retardant additives. |

Meets ASTM E84 Class A fire rating. |

|

Heavy Loads |

High load-bearing capacity (up to 1,000kg per sq. m for heavy-duty models). |

Reinforced fiberglass strands + thickened resin coating. |

Customizable load ratings for specific needs. |

Cost-Effectiveness of FRP Walkway Systems

- Low Maintenance Costs of Walkway FRP: Walkway FRP requires minimal maintenance compared to traditional materials—no painting, rust removal, or wood treatment needed. ZJ Composites’ FRP walkway systems only need occasional cleaning with mild soap and water to remove debris, reducing annual maintenance costs by 70% compared to steel. Over a 20-year lifespan, this translates to significant savings: a FRP walkway grating system costs 50% less to maintain than a steel equivalent, making it a cost-wise investment for clients.

- Long Lifespan and Durability of FRP Walkway: FRP walkway systems have a lifespan of 20–30 years, compared to 10–15 years for steel and 5–8 years for wood. ZJ Composites’ rigorous testing (including UV resistance, impact resistance, and load testing) ensures their FRP walkway grating retains performance over decades, eliminating the need for frequent replacements. Wholesalers can emphasize this long lifespan to clients: while FRP walkway may have a slightly higher upfront cost than wood, it pays for itself in reduced replacement and maintenance expenses over time.

FRP Walkway FAQS

Can FRP Walkway Grating Withstand Extreme Temperatures?

Yes—ZJ Composites’ FRP walkway grating is designed to withstand extreme temperatures, from -40°C (cold storage facilities) to 120°C (industrial ovens or refineries). The resin matrix is formulated with heat stabilizers or cold-resistant additives (depending on the application), and the fiberglass core retains strength across temperature fluctuations. For example, a walkway FRP in a desert refinery won’t warp in 50°C heat, and one in a freezer won’t become brittle in sub-zero temperatures. Wholesalers can assure clients that the grating performs reliably in their specific climate or facility conditions.

Is FRP Walkway Suitable for Outdoor Public Spaces (e.g., Park Paths)?

Absolutely—FRP walkway is an excellent choice for outdoor public spaces. ZJ Composites’ outdoor walkway FRP includes UV stabilizers to prevent fading or brittleness from sunlight, and the non-slip surface is safe for pedestrians (even in rain or snow). It’s also lightweight enough for easy installation on uneven terrain and durable enough to handle heavy foot traffic. For parks or recreational areas, FRP walkway can be customized in different colors (to match landscape design) and cut into curved shapes— adding aesthetic value while maintaining functionality.

How Does the Load Capacity of FRP Walkway Compare to Steel?

FRP walkway has a load capacity comparable to steel of the same thickness—ZJ Composites’ heavy-duty FRP walkway grating can support up to 1,000kg per square meter, enough for small equipment or forklift traffic (with proper support spacing). While steel may have a slightly higher maximum load capacity, FRP walkway offers a better strength-to-weight ratio: it’s 70% lighter than steel but retains 80–90% of the load capacity. This makes it ideal for applications where weight is a concern (e.g., rooftop walkways, mezzanines) without sacrificing performance.

Can FRP Walkway Grating Be Customized to Fit Odd Shapes or Sizes?

Yes—ZJ Composites offers full customization for FRP walkway grating to fit odd shapes, cutouts, or sizes. Whether clients need a curved walkway FRP for a circular platform or custom cutouts for pipes/columns in an industrial facility, the company uses CNC cutting equipment to precision-tailor panels. Clients simply provide measurements or CAD drawings, and ZJ Composites delivers pre-cut panels ready for installation— eliminating on-site cutting waste and ensuring a perfect fit. Wholesalers can note that this customization is available for bulk orders, making it easy to serve clients with unique project requirements.

Where Can Wholesalers Source High-Quality FRP Walkway Systems?

Zhaojia Composites Co., Ltd (ZJ Composites) manufactures premium FRP walkway, FRP walkway grating, and walkway FRP systems— all tested for durability, safety, and performance. With global export experience, perfect testing equipment, and a focus on customer collaboration, they provide wholesalers with reliable, customizable solutions that meet diverse client needs.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025