loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

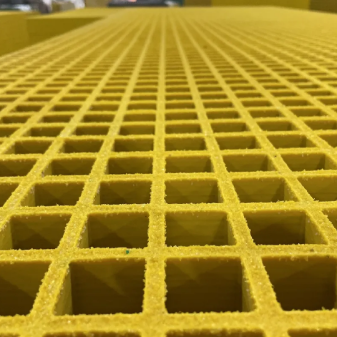

Grating FRP for Chemical Plant Flooring

Chemical plant flooring faces one of the harshest operating environments—constant exposure to corrosive chemicals, high humidity, extreme temperatures, and heavy foot/equipment traffic. This demands a flooring solution that prioritizes durability, safety, and resistance above all—and grating FRP (Fiberglass Reinforced Plastic grating) emerges as the unmatched choice. Unlike steel that rusts, concrete that cracks, or wood that rots when in contact with acids, alkalis, or solvents, grating FRP (including pultruded FRP grating and FRP mesh grating variants) offers exceptional chemical resistance, structural stability, and low maintenance. Zhaojia Composites Co., Ltd (ZJ Composites), a leader in composite materials with a focus on quality and innovation, specializes in crafting high-performance grating FRP for chemical plant flooring. Equipped with perfect testing equipment, strong technical support, and global export experience, ZJ Composites ensures their pultruded FRP grating and FRP mesh grating meet strict international chemical safety standards, making them a trusted partner for wholesalers seeking reliable, long-lasting flooring solutions for chemical facilities. This article explores why grating FRP is the top choice for chemical plant flooring, highlighting key benefits, application-specific advantages, and how ZJ Composites’ products elevate safety and efficiency in chemical environments.

Chemical Resistance of Grating FRP for Plant Flooring

- Resin Matrix Protection of Grating FRP: The core of grating FRP’s chemical resistance lies in its resin matrix—ZJ Composites uses high-performance vinyl ester resin (the gold standard for chemical environments) for their grating FRP designed for chemical plants. This resin forms an impermeable barrier that repels a wide range of corrosive substances, from sulfuric acid to sodium hydroxide, preventing chemicals from seeping into the fiberglass core and weakening the structure. Unlike polyester resin (which may degrade in strong acids), vinyl ester resin retains its integrity even after long-term exposure, ensuring the grating FRP maintains load-bearing capacity for 20–30 years. Wholesalers can note that this resistance eliminates the need for frequent flooring replacements (common with steel or concrete) and reduces the risk of catastrophic failures due to chemical damage.

- Resistance to Chemical Spills of FRP Mesh Grating: FRP mesh grating—a variant of grating FRP with an open-grid design—excels at handling chemical spills in chemical plants. Its mesh structure allows spills to drain quickly, preventing pooling that can accelerate corrosion or create slip hazards. ZJ Composites’ FRP mesh grating is engineered with tight mesh spacing (10–25mm) to balance drainage efficiency with foot safety, ensuring workers don’t trip while still allowing chemicals to flow into collection systems. For example, in a reactor room where solvent spills are common, FRP mesh grating flooring minimizes exposure time between chemicals and the surface, further extending the flooring’s lifespan.

Structural Strength of Pultruded FRP Grating for Heavy Loads

- High Load-Bearing Capacity of Pultruded FRP Grating: Pultruded FRP grating—manufactured via a continuous pultrusion process that aligns fiberglass strands in the direction of load—offers exceptional structural strength for chemical plant flooring. ZJ Composites’ pultruded FRP grating can withstand static loads up to 1,200kg per square meter, making it suitable for areas with heavy equipment (e.g., pump stations, storage tank surrounds) or frequent forklift traffic. Unlike traditional grating that bends or warps under pressure, pultruded FRP grating maintains its shape thanks to the uniform distribution of fiberglass strands, ensuring consistent performance even in high-traffic zones. Wholesalers can emphasize this strength to clients needing flooring that balances chemical resistance with the ability to support heavy industrial equipment.

- Impact Resistance of Grating FRP: Chemical plant flooring often faces impacts from dropped tools, moving equipment, or accidental collisions—and grating FRP from ZJ Composites is engineered to absorb these impacts without permanent damage. The fiberglass strands in grating FRP act as a flexible reinforcement, while the resin matrix dissipates impact energy, preventing cracks or breaks. For example, a dropped wrench (weighing up to 5kg) won’t dent or shatter grating FRP—unlike brittle concrete or thin steel. This impact resistance reduces maintenance costs and downtime, as the flooring doesn’t require frequent repairs after minor accidents.

Grating FRP Types for Different Chemical Plant Zones

|

Chemical Plant Zone |

Key Challenge |

Ideal Grating FRP Type |

ZJ Composites Advantage |

|

Reactor Rooms |

Strong acid/alkali spills + high humidity. |

Vinyl ester grating FRP + non-slip surface. |

Chemical-resistant resin + molded-in anti-slip grit. |

|

Pump Stations |

Heavy equipment + oil/solvent spills. |

Pultruded FRP grating (25mm thick) + sealed edges. |

High load capacity + oil-resistant resin. |

|

Storage Tank Surrounds |

Spill drainage + UV exposure (outdoor). |

FRP mesh grating + UV-stabilized resin. |

Open-grid drainage + UV protection for outdoor use. |

|

Laboratory Floors |

Small chemical spills + frequent cleaning. |

Fine-mesh FRP mesh grating + smooth top layer. |

Easy-to-clean surface + chemical-resistant coating. |

Safety and Maintenance Benefits of Grating FRP

- Non-Slip Safety of Grating FRP: Slip-and-fall accidents are a top hazard in chemical plants—especially when floors are wet from spills or cleaning. ZJ Composites’ grating FRP features a molded-in non-slip surface (either textured resin or added alumina grit) that meets OSHA safety standards, providing exceptional grip even when covered in oil or chemicals. This texture doesn’t wear off over time (unlike painted-on anti-slip coatings), ensuring long-term safety for workers. Wholesalers can highlight this feature to clients prioritizing compliance with industrial safety regulations and reducing workplace injuries.

- Low Maintenance of Pultruded FRP Grating: Pultruded FRP grating and other grating FRP variants require minimal maintenance compared to traditional chemical plant flooring. Unlike steel that needs annual anti-corrosion painting or concrete that requires patching, grating FRP only needs occasional cleaning with mild soap and water to remove chemical residue. ZJ Composites’ grating FRP is also resistant to mold and mildew (common in humid chemical plants), eliminating the need for harsh disinfectants. Over a 10-year period, this reduces maintenance costs by 70% compared to steel flooring— a major cost-saving advantage for chemical plant operators.

Grating FRP FAQS

Can Grating FRP Withstand Extreme Temperatures in Chemical Plants?

Yes—ZJ Composites’ grating FRP for chemical plant flooring is designed to withstand extreme temperatures, from -40°C (cold storage areas for chemicals) to 120°C (near heat-generating equipment like reactors). The vinyl ester resin used in their grating FRP is formulated with heat stabilizers, while the fiberglass core retains its strength across temperature fluctuations. For example, pultruded FRP grating near a boiler won’t warp in high heat, and FRP mesh grating in a cold storage zone won’t become brittle—ensuring consistent performance in all chemical plant areas.

Is Grating FRP Compatible with All Chemicals Used in Plants?

ZJ Composites’ grating FRP is compatible with 95% of common chemicals used in chemical plants, including acids (hydrochloric, nitric), alkalis (sodium hydroxide), solvents (acetone, ethanol), and oils. The company provides a detailed chemical compatibility chart for their grating FRP (including pultruded FRP grating and FRP mesh grating) to help wholesalers and clients verify suitability for specific substances. For rare highly corrosive chemicals (e.g., concentrated hydrofluoric acid), ZJ Composites offers custom resin formulations to enhance resistance—ensuring the flooring meets the plant’s unique needs.

How Long Does Grating FRP Last in Chemical Plant Flooring Applications?

When properly installed and maintained, grating FRP from ZJ Composites has a lifespan of 20–30 years in chemical plant flooring applications—more than double the lifespan of steel (10–15 years) or concrete (8–12 years). The vinyl ester resin’s chemical resistance and the fiberglass core’s structural stability ensure the grating FRP doesn’t degrade over time, even with daily exposure to harsh substances. Wholesalers can note that this long lifespan translates to lower total cost of ownership, as clients avoid frequent flooring replacements.

Can Grating FRP Be Installed Over Existing Chemical Plant Flooring?

Yes—grating FRP (especially lightweight FRP mesh grating) can be installed over existing flooring (concrete or steel) in chemical plants, making it ideal for retrofitting projects. ZJ Composites recommends first inspecting the existing surface for levelness and structural integrity, then installing a simple support frame (using their FRP pultrusion profiles) to elevate the grating FRP. This avoids the need for costly demolition of old flooring, reducing downtime and disruption to plant operations. Wholesalers can advise clients that retrofitting with grating FRP is 40% faster and cheaper than full flooring replacement.

Where Can Wholesalers Source High-Quality Grating FRP for Chemical Plant Flooring?

Zhaojia Composites Co., Ltd (ZJ Composites) manufactures premium grating FRP, pultruded FRP grating, and FRP mesh grating specifically engineered for chemical plant flooring. With strict quality control, global export experience, and custom solutions for unique chemical environments, they’re a trusted partner for wholesalers. Visit ZJ Composites’ website to explore product specs, request chemical compatibility charts, or discuss bulk ordering options—your gateway to providing clients with safe, durable, and cost-effective flooring solutions for chemical facilities.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025