läser in...

- 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, Kina

- admin@zjcomposites.com

- +86 15097380338

- Välkommen att besöka vår hemsida!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- engelsk

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

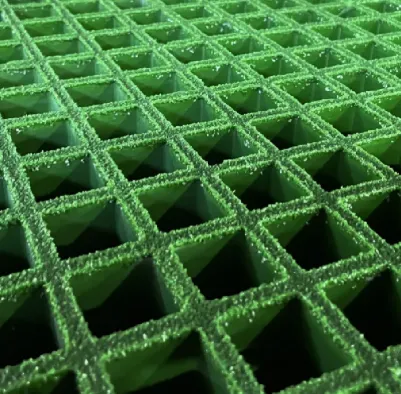

FRP Grating: The Smart Solution for Durable, Lightweight Industrial Flooring

Lightweight, non-conductive, and highly durable, frp grating has become a mainstay across a range of industries looking for resilient, cost-effective flooring and walkway solutions.

Understanding the Versatile Functionality of FRP Grating

FRP grating, or fiber-reinforced plastic grating, is a composite material made from fiberglass and resin, offering significant advantages over traditional materials like steel or aluminum. It is widely used in chemical plants, marine environments, food processing facilities, and wastewater treatment plants thanks to its resistance to corrosion, fire, and chemical exposure.

What makes frp grating for sale so appealing is not only its performance but also its adaptability. Available in molded or pultruded forms, it provides flexibility depending on load-bearing needs and structural requirements. Molded frp grating is ideal for areas requiring bi-directional strength, while pultruded versions excel in applications where high strength-to-weight ratio is critical.

These features, along with its non-slip surface and low maintenance demands, make frp grating a valuable investment for any industrial setting. Many frp grating suppliers now provide a wide range of options tailored for different load capacities and environmental conditions.

Heavy FRP Grating vs. Light FRP Grating: Which One Should You Choose?

When selecting the right product from frp grating suppliers, understanding the differences between heavy-duty and lightweight versions is essential. Heavy frp grating is engineered to bear more substantial static and dynamic loads, making it suitable for high-traffic industrial floors, platforms, and equipment access points.

Lättvikt frp grating, on the other hand, is ideal for areas with pedestrian traffic or low mechanical stress, such as mezzanines, catwalks, or safety covers. Despite being lighter in weight, it maintains excellent corrosion resistance and durability.

Cost is also a deciding factor. The frp grating price for heavy-duty applications is typically higher due to the increased material density and reinforcement. However, the investment pays off in environments where safety and longevity are paramount. Lightweight options offer budget-friendly alternatives without sacrificing essential performance, and many frp grating for sale listings provide detailed specifications to help buyers make informed decisions.

Extending Lifespan: How to Prevent UV Aging of FRP Grating

One of the standout advantages of frp grating is its ability to withstand long-term outdoor exposure. However, like all composite materials, prolonged exposure to UV radiation can lead to surface degradation if not properly protected.

To delay aging, frp grating suppliers often recommend UV-resistant coatings or surface veils integrated during the manufacturing process. These protective layers significantly slow the effects of sun exposure, keeping the grating strong and safe over many years.

Another effective approach is the use of pigmented resins that act as UV inhibitors, maintaining color vibrancy and mechanical strength. Regular cleaning to remove surface contaminants and occasional application of compatible UV coatings can further increase durability. For customers browsing frp grating for sale, it’s essential to ask about the UV protection level included with the product.

This makes UV-resistant frp grating not just an industrial product, but a long-term investment—especially in outdoor applications such as oil platforms, wastewater tanks, or rooftop access platforms where sunlight exposure is constant.

Market Trends and Performance Outlook of FRP Grating

The global demand for frp grating continues to grow as industries increasingly shift toward lightweight, corrosion-resistant alternatives. This demand surge is also influenced by stricter workplace safety regulations and environmental standards. The wide availability of frp grating for sale online has further simplified procurement and broadened accessibility across sectors.

Leading frp grating suppliers now offer customized solutions, such as fire-retardant variants and high-impact designs, to meet specific project requirements. The flexibility of frp grating, in terms of design and function, places it at the forefront of modern infrastructure materials.

Furthermore, the competitive frp grating price has improved significantly thanks to advancements in production technology. Pultrusion techniques have become more efficient, reducing material waste while enhancing quality. Buyers today can find frp grating for sale at better rates than ever before, without compromising on performance or longevity.

As awareness of its benefits increases, frp grating is becoming the default choice for both retrofit and new-build industrial projects. From oil platforms to food-grade cleanrooms, this material offers unmatched value in every category.

FRP Grating FAQs

What is the difference between molded and pultruded frp grating?

Molded frp grating is formed in a mold and provides strength in two directions, making it ideal for applications with multi-directional load requirements. Pultruded frp grating, produced through a continuous process, has higher longitudinal strength and is preferred for longer spans.

Is heavy-duty frp grating worth the extra cost?

Yes, heavy-duty frp grating offers superior load-bearing capacity and impact resistance. If your environment involves forklifts, heavy equipment, or constant heavy traffic, investing in heavy frp grating is cost-effective in the long run.

How can I tell if a supplier offers UV-resistant frp grating for sale?

Most reputable frp grating suppliers will list UV resistance in their product specifications. Look for features such as surface veils, pigmented resins, or added coatings. You can also request a UV resistance certification before purchasing.

What’s the average frp grating price per square meter?

The frp grating price can range from $30 to $100 per square meter depending on thickness, load rating, resin type, and UV protection. Always compare products based on technical specs, not just price, to ensure you get the right grating for your application.

How long can frp grating last in outdoor environments?

With proper UV protection and periodic maintenance, frp grating can last over 25 years in outdoor conditions. Its durability in corrosive and wet environments also extends its service life beyond traditional metal gratings.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNyheterNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNyheterNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNyheterNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNyheterNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNyheterNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNyheterNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNyheterNov.11,2025