ea kenya...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Rea u amohela ho etela sebaka sa rona sa Marang-rang!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Senyesemane

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Durability of Grating FRP in Harsh Conditions

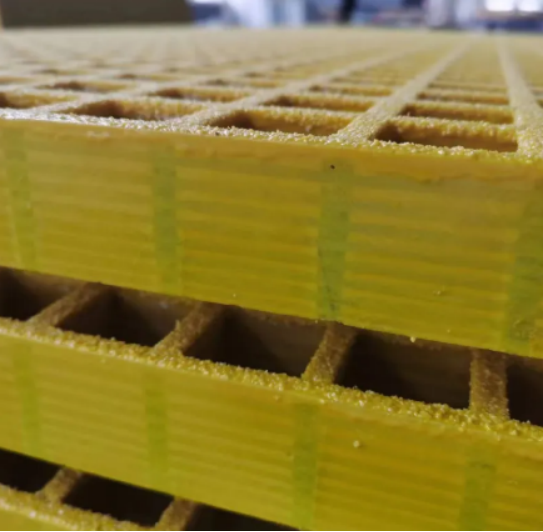

In the realm of industrial and infrastructure materials, grating FRP, FRP grating, and FRP grating panels have emerged as resilient solutions, especially when confronting harsh environmental conditions. ZJ Composites, a leading provider in composite materials, offers a comprehensive range of FRP grating products designed to withstand the most demanding scenarios.

Corrosion Resistance of Grating FRP

- Grating FRP from ZJ Composites demonstrates exceptional resistance to corrosion, making it ideal for harsh environments. Unlike traditional metal gratings, FRP grating does not rust or degrade when exposed to moisture, chemicals, or saltwater. This property ensures that grating FRP remains structurally sound in coastal areas, chemical processing plants, and wastewater treatment facilities, where corrosive elements are prevalent. The non-corrosive nature of FRP grating eliminates the need for regular painting or protective coatings, reducing maintenance costs over the product’s lifespan.

- The composite structure of grating FRP combines glass fibers and thermosetting resins, creating a barrier against corrosive agents. ZJ Composites’ advanced manufacturing processes enhance this barrier, ensuring that the grating maintains its integrity even in prolonged contact with aggressive substances. Whether exposed to acids, alkalis, or other corrosive chemicals, grating FRP continues to perform reliably, making it a cost-effective solution for industries where corrosion is a major concern.

- In marine environments, where saltwater and humidity can quickly degrade metal components, grating FRP offers a durable alternative. The grating resists the effects of salt spray, preventing the formation of rust and maintaining its structural strength. This durability ensures that installations in ports, offshore platforms, and coastal infrastructure remain safe and functional for years, reducing the need for frequent replacements and minimizing downtime.

Weather Resistance of Tlhaloso ea FRP

- FRP grating from ZJ Composites is engineered to withstand extreme weather conditions, making it suitable for outdoor applications in various climates. The material resists fading, cracking, and warping when exposed to prolonged sunlight, heavy rainfall, or freezing temperatures. This weather resistance ensures that FRP grating maintains its aesthetic appeal and structural integrity in outdoor walkways, platforms, and staircases, even in regions with harsh weather patterns.

- The UV - resistant properties of FRP grating prevent the degradation of the resin matrix caused by sunlight exposure. ZJ Composites incorporates specialized additives into the resin to enhance UV resistance, ensuring that the grating remains stable and does not become brittle over time. This feature is particularly important for outdoor installations, where prolonged sun exposure can compromise the durability of other materials.

- In areas prone to heavy snowfall or extreme temperatures, FRP grating demonstrates remarkable resilience. The material does not contract or expand significantly with temperature changes, reducing the risk of cracks or structural damage. Additionally, the non - slippery surface of FRP grating remains safe even when wet or icy, enhancing worker safety in harsh weather conditions. This combination of weather resistance and safety features makes FRP grating an ideal choice for outdoor industrial and commercial applications.

Chemical Resistance of FRP Grating Panels

- FRP grating panels exhibit excellent chemical resistance, making them suitable for use in environments where exposure to various chemicals is inevitable. ZJ Composites’ FRP grating panels are designed to withstand contact with a wide range of chemicals, including acids, bases, solvents, and hydrocarbons. This resistance ensures that the panels remain functional and safe in chemical plants, laboratories, and other industrial settings where chemical spills or exposure are common.

- The chemical resistance of FRP grating panels is derived from the inert nature of the thermosetting resins used in their construction. These resins form a stable matrix that does not react with most chemicals, providing a reliable barrier against corrosion and degradation. ZJ Composites’ rigorous testing ensures that their FRP grating panels meet industry standards for chemical resistance, giving wholesalers confidence in recommending these products to clients in chemical - intensive industries.

- In applications where frequent chemical cleaning or exposure to harsh cleaning agents is required, FRP grating panels outperform traditional materials. The panels do not absorb chemicals, making them easy to clean and maintain. This property not only extends the lifespan of the grating but also reduces the risk of chemical contamination, ensuring a safe working environment for employees.

Impact and Load Resistance of Grating FRP

- Grating FRP from ZJ Composites offers significant impact and load resistance, making it a durable choice for high - traffic areas and heavy - duty applications. Despite its lightweight nature, FRP grating can withstand substantial loads without deforming or breaking, making it suitable for industrial floors, platforms, and walkways. The composite structure of the grating distributes loads evenly, enhancing its resistance to impact and mechanical stress.

- The impact resistance of grating FRP ensures that it remains intact even when subjected to sudden heavy loads or falling objects. This feature is crucial in manufacturing facilities, warehouses, and other environments where equipment or materials may accidentally impact the grating. Unlike brittle materials, FRP grating flexes under impact and returns to its original shape, reducing the risk of cracks or structural damage.

- ZJ Composites’ grating FRP is designed to meet specific load - bearing requirements, ensuring that it can safely support the intended use. Whether used in pedestrian areas or for heavy machinery, the grating provides reliable performance and durability. The load resistance of FRP grating, combined with its lightweight design, makes it an efficient and cost - effective solution for a wide range of applications.

Grating FRP FAQS

How does grating FRP compare to traditional metal gratings in terms of durability?

Grating FRP outperforms traditional metal gratings in harsh conditions due to its superior corrosion and weather resistance. Unlike metal gratings, which rust and degrade over time when exposed to moisture and chemicals, grating FRP remains structurally sound and requires minimal maintenance. This durability results in lower life - cycle costs and longer service life for FRP grating compared to metal alternatives.

Can FRP grating withstand extreme temperature fluctuations?

Yes, FRP grating from ZJ Composites is designed to withstand extreme temperature fluctuations. The material has a low coefficient of thermal expansion, meaning it does not expand or contract significantly with temperature changes. This property prevents cracking and structural damage, making FRP grating suitable for use in environments with wide temperature variations.

What is the expected lifespan of FRP grating panels in harsh conditions?

With proper installation and maintenance, FRP grating panels can last 20 years or more in harsh conditions. ZJ Composites’ high - quality materials and manufacturing processes ensure that the panels resist degradation from corrosion, weather, and chemical exposure, providing long - term durability and performance.

Is grating FRP suitable for outdoor applications in coastal areas?

Yes, grating FRP is an excellent choice for outdoor applications in coastal areas. The material resists saltwater corrosion and UV degradation, making it ideal for use in ports, marinas, and other coastal infrastructure. ZJ Composites’ FRP grating maintains its strength and integrity in these harsh environments, reducing the need for frequent replacements.

How does ZJ Composites ensure the quality of its FRP grating products?

ZJ Composites ensures the quality of its FRP grating products through rigorous testing and quality control measures. The company uses advanced manufacturing techniques and high - quality raw materials to produce grating that meets industry standards for durability, corrosion resistance, and load - bearing capacity. Each product undergoes thorough inspection to ensure it meets ZJ Composites’ strict quality requirements before it is released to the market.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingLitabaNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersLitabaNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessLitabaNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesLitabaNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectLitabaNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesLitabaNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingLitabaNov.11,2025