loading...

- Nhamba 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Kugamuchirwa kushanyira webhusaiti yedu!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Chirungu

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

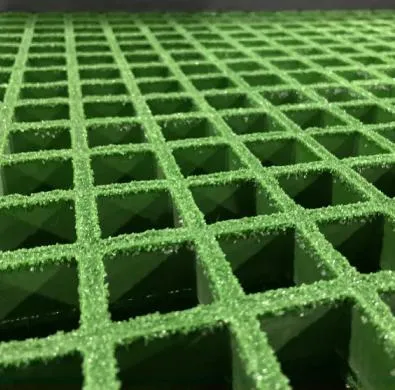

GRP Grating: A Modern Solution for Safe and Durable Access Systems

As industries seek advanced materials that offer strength, safety, and low maintenance, GRP mesh grating has emerged as a reliable solution for a wide range of applications. Whether used in walkways, platforms, or drainage covers, Glass Reinforced Plastic (GRP) provides exceptional performance in both industrial and public settings. Products like GRP moulded grating, GRP walkway grating, and GRP solid top grating offer unique benefits that outperform traditional metal or wooden alternatives in many environments.

Understanding GRP Mesh Grating and Its Core Benefits

GRP mesh grating is a type of fiberglass-reinforced plastic grating known for its high strength-to-weight ratio, excellent corrosion resistance, and non-conductive properties. It is manufactured by combining glass fibers with resin, molded into a grid-like pattern to form a strong and versatile panel.

Advantages of GRP Mesh Grating:

Corrosion resistance: Ideal for wet, salty, or chemical-rich environments

Anti-slip surface: Enhanced safety for foot traffic

Non-conductive: Safe for use near electrical equipment

UV resistance: Suitable for outdoor use

Lightweight and easy to install

Thanks to these benefits, GRP mesh grating is widely used in sectors like marine, water treatment, construction, telecommunications, and power generation.

Common Types of GRP Gratings and Their Applications

Different types of GRP grating serve unique purposes depending on the application. Among the most popular options are GRP moulded grating, GRP walkway grating, and both open mesh GRP grating and GRP solid top grating.

- GRP Moulded Grating

GRP moulded grating is manufactured using a mold process where continuous fiberglass strands are thoroughly wetted with resin and molded into a one-piece, interwoven matrix. This method creates a grating that is strong in both directions and provides excellent resistance to chemical corrosion.

Applications include:

Chemical processing plants

Wastewater treatment facilities

Platforms in offshore environments

Because of its bi-directional strength and resilience, GRP moulded grating is ideal for areas subject to high loads or where long service life is required.

- GRP Walkway Grating

As the name suggests, GRP walkway grating is used to create safe walking surfaces in industrial and commercial settings. It features anti-slip surfaces and high load-bearing capacity, making it a favorite for access routes, maintenance paths, and elevated platforms.

Common use cases:

Walkways around industrial equipment

Stair treads and landings

Access platforms in hazardous environments

Its non-corrosive and fire-retardant properties ensure safety and durability even in challenging conditions.

- Open Mesh GRP Grating and GRP Open Mesh Grating

Both open mesh GRP grating and GRP open mesh grating refer to grating panels with open-grid designs that allow water, debris, and air to pass through. These types are especially useful in outdoor applications or areas where drainage is necessary.

Use cases include:

Drainage trench covers

Catwalks and elevated walkways

Platforms in marine or dockside environments

Their open design reduces the risk of puddling and provides better ventilation, while still offering slip resistance and structural integrity.

- GRP Solid Top Grating

GRP solid top grating is a variation of standard mesh grating where the top surface is covered, offering a closed deck. It is ideal for environments where falling tools, contamination, or small parts need to be prevented from slipping through gaps.

Applications:

Walkways over sensitive equipment

Hygienic surfaces in food or pharma environments

Rooftop access zones

The solid surface ensures better containment and cleanliness, without sacrificing the core benefits of GRP material.

Why Choose GRP Gratings Over Traditional Materials?

When compared to steel, aluminum, or timber, GRP gratings deliver a combination of performance, safety, and lifecycle cost savings that few materials can match.

Key Comparisons:

Corrosion resistance: GRP won’t rust or corrode like steel, even in harsh weather or chemical environments.

Low maintenance: Unlike wood, GRP doesn’t rot, warp, or require painting.

Lightweight: Easier and cheaper to install without heavy equipment.

Non-sparking and non-conductive: Much safer around electrical systems.

Slip resistance: Engineered surfaces improve grip in wet or oily areas.

For facilities managers, engineers, and architects, GRP mesh grating, GRP walkway grating, and GRP solid top grating offer a long-term solution that meets both safety and operational demands.

As industries continue to demand more from their infrastructure, GRP mesh grating, including GRP moulded grating, GRP walkway grating, open mesh GRP grating, and GRP solid top grating, stands out as a reliable and modern alternative to traditional flooring and access systems.

Its blend of safety, durability, low maintenance, and cost-efficiency makes it suitable for everything from factories and chemical plants to public infrastructure and rooftops. Whether your priority is drainage, safety, or containment, there's a GRP grating solution designed for the job.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025