loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 18, 2025 01:49

Back to list

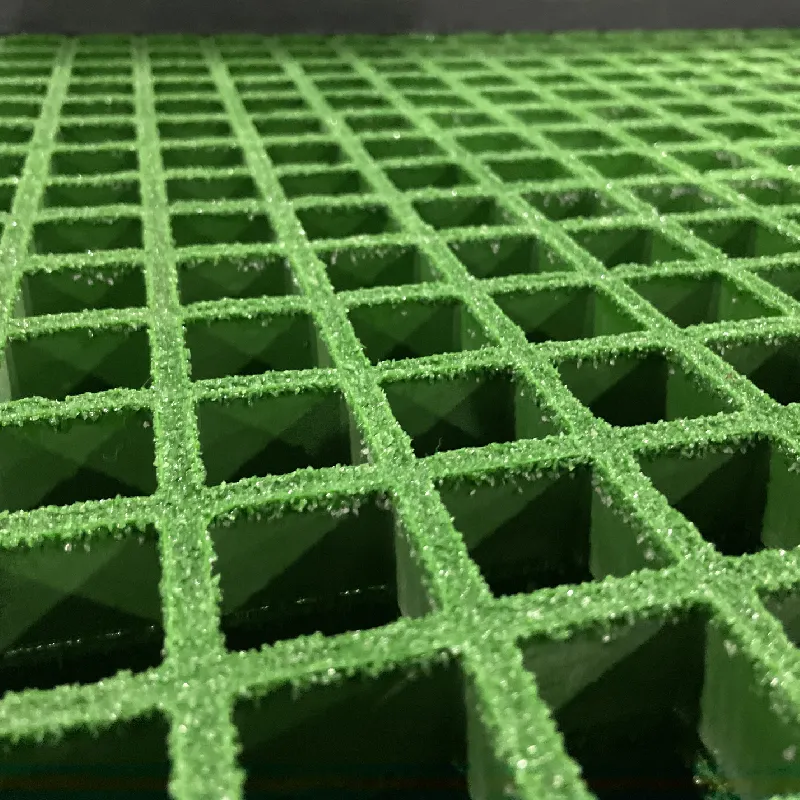

Smaller Open Mesh Area FRP Mini Mesh Grating

Fibreglass reinforced plastic grating, often simply referred to as FRP grating, is transforming industries with its unique properties and versatility. This modern material is becoming a staple in environments where traditional materials like wood, steel, or aluminum might fail or require frequent maintenance, showcasing unparalleled benefits in a plethora of applications.

Environmentally, FRP grating contributes positively. It represents a move towards sustainable construction practices. With a long lifespan and recyclability, the environmental footprint of FRP grating is considerably lower than traditional alternatives. The material’s longevity and low maintenance mean fewer replacements and repairs, leading to less waste over time and a sustainable solution for forward-thinking industries. Expert manufacturers understand these benefits and strive to innovate further. Advances in resin formulations and fiberglass technology continue to enhance the performance and applications of FRP grating. Professionals in the industry emphasize the importance of sourcing from reputable manufacturers who comply with international quality standards. Such compliance ensures the purchase of FRP gratings that deliver consistency in performance and safety across all applications. Industry authorities have increasingly acknowledged fibreglass reinforced plastic grating as a superior alternative for grating solutions. Their endorsements lend authority to the growing trust in the material. Certification and testing provide added layers of validation, ensuring that the grating meets and exceeds specific load-bearing and durability criteria. Potential users should seek out products with clear certification labels as a testament to quality. Businesses have readily shared their positive experiences, highlighting not only the functional advantages but also the operational efficiencies gained through using FRP grating. These testimonials feed into the material's burgeoning reputation, creating a network of trustworthiness that further bolsters its adoption across sectors. In conclusion, FRP grating represents a forward-looking path in industrial materials, offering a perfect amalgamation of strength, safety, and sustainability. Its role in advancing industrial capabilities while reducing operational costs has solidified fibreglass reinforced plastic grating's stance as a preferred solution for contemporary challenges faced by industries worldwide. For those seeking a practical, reliable, and sustainable grating solution, fibreglass reinforced plastic grating is the unequivocal answer.

Environmentally, FRP grating contributes positively. It represents a move towards sustainable construction practices. With a long lifespan and recyclability, the environmental footprint of FRP grating is considerably lower than traditional alternatives. The material’s longevity and low maintenance mean fewer replacements and repairs, leading to less waste over time and a sustainable solution for forward-thinking industries. Expert manufacturers understand these benefits and strive to innovate further. Advances in resin formulations and fiberglass technology continue to enhance the performance and applications of FRP grating. Professionals in the industry emphasize the importance of sourcing from reputable manufacturers who comply with international quality standards. Such compliance ensures the purchase of FRP gratings that deliver consistency in performance and safety across all applications. Industry authorities have increasingly acknowledged fibreglass reinforced plastic grating as a superior alternative for grating solutions. Their endorsements lend authority to the growing trust in the material. Certification and testing provide added layers of validation, ensuring that the grating meets and exceeds specific load-bearing and durability criteria. Potential users should seek out products with clear certification labels as a testament to quality. Businesses have readily shared their positive experiences, highlighting not only the functional advantages but also the operational efficiencies gained through using FRP grating. These testimonials feed into the material's burgeoning reputation, creating a network of trustworthiness that further bolsters its adoption across sectors. In conclusion, FRP grating represents a forward-looking path in industrial materials, offering a perfect amalgamation of strength, safety, and sustainability. Its role in advancing industrial capabilities while reducing operational costs has solidified fibreglass reinforced plastic grating's stance as a preferred solution for contemporary challenges faced by industries worldwide. For those seeking a practical, reliable, and sustainable grating solution, fibreglass reinforced plastic grating is the unequivocal answer.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025