loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

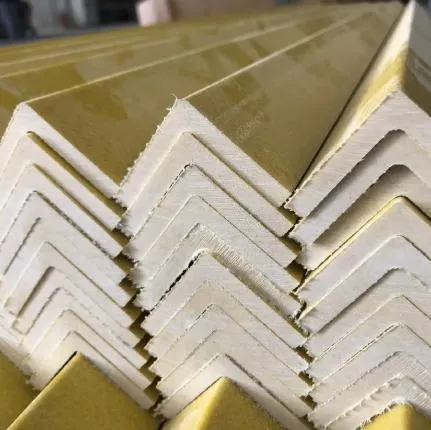

The Strength and Versatility of FRP Profiles

FRP profiles are revolutionizing various industries with their unique combination of strength, durability, and lightweight properties. Made from fiber-reinforced polymers (FRP), these profiles offer a range of applications across construction, transportation, and manufacturing. The growing demand for innovative materials has led to the rise of FRP pultruded profiles and FRP pultruded sections, which are becoming increasingly popular for both structural and non-structural uses. Let’s dive into the benefits and applications of these advanced materials.

What Are FRP Profiles and Their Key Advantages?

FRP profiles are specially designed components made from fiber-reinforced polymer, offering superior strength while maintaining a lightweight nature. These profiles are highly resistant to corrosion, which makes them ideal for use in harsh environments where metal components may deteriorate. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, making them highly suitable for industries such as construction, marine, and chemical. Their exceptional durability ensures long-lasting performance and reduces the need for frequent maintenance, making them cost-effective in the long run.

The Power of FRP Pultruded Profiles

One of the most advanced manufacturing methods for producing FRP pultruded profiles is pultrusion. This technique involves pulling a resin-soaked fiber material through a heated die to form continuous profiles with uniform cross-sections. FRP pultruded profiles are known for their strength, rigidity, and dimensional accuracy, making them ideal for structural applications. They offer excellent resistance to chemical attack, UV degradation, and extreme weather conditions. With a wide variety of shapes and sizes available, FRP pultruded profiles provide versatility across a range of industries, including construction, infrastructure, and industrial applications.

Applications of FRP Pultruded Sections

FRP pultruded sections are versatile components that are increasingly being used for both residential and industrial applications. These sections are commonly used in the construction of bridges, railings, ladders, and walkways due to their lightweight yet robust nature. The FRP pultruded sections are designed to handle significant loads while being resistant to corrosion and electrical conductivity. In addition to structural uses, these sections are also used in transportation, electrical, and chemical industries, where the material’s resistance to heat, fire, and chemicals is a major advantage. The strength-to-weight ratio of FRP pultruded sections makes them ideal for applications that require lightweight but strong materials.

The Benefits of FRP Pultrusion for Custom Profiles

The pultrusion process offers significant benefits when it comes to creating FRP pultruded profiles tailored to specific needs. This process allows manufacturers to produce highly customizable profiles in terms of both shape and size, giving engineers and designers flexibility to create components that meet precise structural and aesthetic requirements. FRP pultruded profiles can be tailored to specific applications, whether it’s for enhanced strength, UV resistance, or fire retardance. This customization makes them an ideal choice for a wide variety of applications, from infrastructure projects to high-tech manufacturing needs.

Why Choose FRP Profiles for Your Next Project?

Choosing FRP profiles, especially FRP pultruded profiles and FRP pultruded sections, offers many advantages over traditional materials. Their lightweight yet strong nature, combined with high resistance to corrosion and chemical attack, makes them ideal for use in a wide range of sectors. Whether you’re working on construction, electrical systems, or manufacturing, FRP profiles offer durability, versatility, and cost-effectiveness that will meet the demands of any project. Moreover, the flexibility in design and ease of maintenance ensure that FRP pultruded sections will provide long-term performance and value for money.

In conclusion, FRP profiles, including FRP pultruded profiles and FRP pultruded sections, are cutting-edge materials that provide long-lasting, reliable performance across multiple industries. With their unmatched strength, light weight, and resistance to corrosion, they offer a superior alternative to traditional materials. Whether you’re looking for custom designs or standard solutions, FRP profiles are the smart choice for a range of applications, ensuring both durability and cost-effectiveness for your projects.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025