loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Leading FRP Grating Suppliers - Durable & Corrosion-Resistant Solutions

Understanding the Critical Role of FRP Grating in Industrial Infrastructure

In the demanding landscapes of modern industry, the selection of robust, durable, and corrosion-resistant materials for flooring, platforms, and trench covers is paramount. Fiberglass Reinforced Polymer (FRP) grating has emerged as a superior alternative to traditional materials like steel, offering unparalleled performance in harsh environments. As a leading solution for industrial applications, the choice of reliable frp grating suppliers is critical. This comprehensive guide delves into the nuances of FRP grating, covering its manufacturing, technical advantages, application scenarios, and key considerations for procurement, ensuring B2B decision-makers are equipped with the knowledge to make informed choices.

Key Industry Trends in FRP Grating

The market for FRP grating is experiencing dynamic growth, driven by several overarching industry trends. Sustainability is a major factor, with increasing demand for materials that offer extended service life and reduced environmental impact through lower maintenance requirements and energy consumption in production compared to metallic alternatives. There's also a growing emphasis on enhanced safety features, leading to advancements in anti-slip surfaces and ergonomic designs that reduce fatigue for workers. Customization and modularity are becoming standard, enabling more efficient installation and adaptation to unique site requirements. Furthermore, the integration of advanced composites, such as those used by forward-thinking frp grating suppliers, is pushing performance boundaries, offering higher strength-to-weight ratios and superior resistance to extreme chemical and thermal conditions. The expansion into new application areas, particularly in offshore energy, wastewater treatment, and architectural design, further underscores the versatility and increasing adoption of FRP solutions.

The Meticulous Manufacturing Process of FRP Grating

The production of high-quality FRP grating involves a sophisticated, multi-stage manufacturing process, primarily utilizing either the molded or pultruded method, each designed to achieve specific performance characteristics. Reputable frp grating suppliers adhere to stringent quality control measures throughout the entire production lifecycle, from raw material selection to final product testing.

Core Materials:

- Resins: The matrix material, typically polyester (orthophthalic, isophthalic) or vinylester, selected based on the required corrosion resistance and mechanical properties. Isophthalic resins offer good chemical resistance, while vinylester resins provide superior resistance to a broader range of corrosive chemicals and higher temperatures. Phenolic resins are used for fire resistance.

- Reinforcements: Primarily E-glass fibers (rovings, mats), which provide the structural integrity and strength. The arrangement and quantity of these fibers dictate the grating's load-bearing capacity and impact resistance.

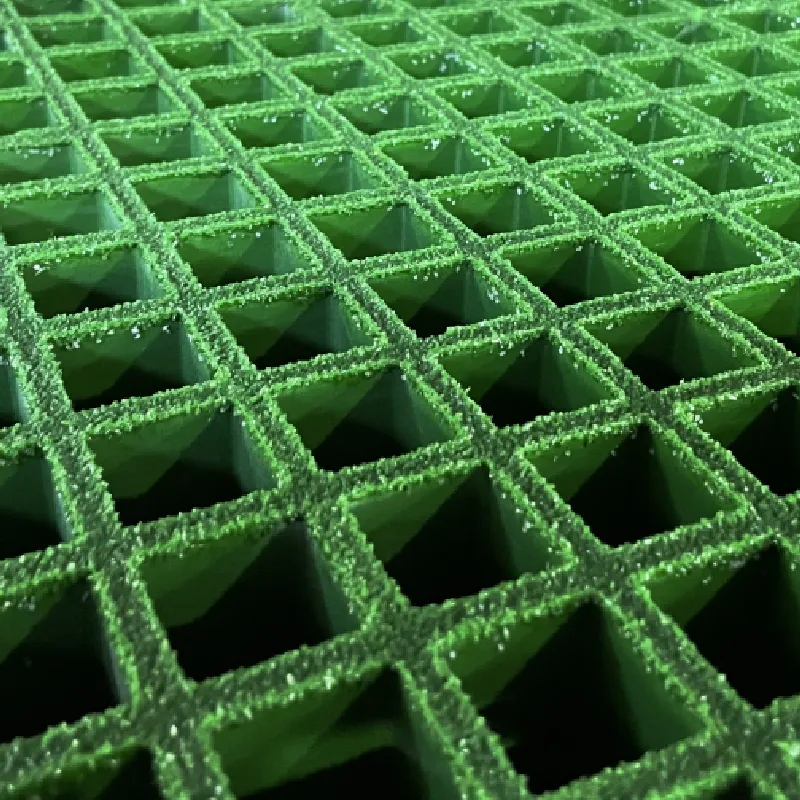

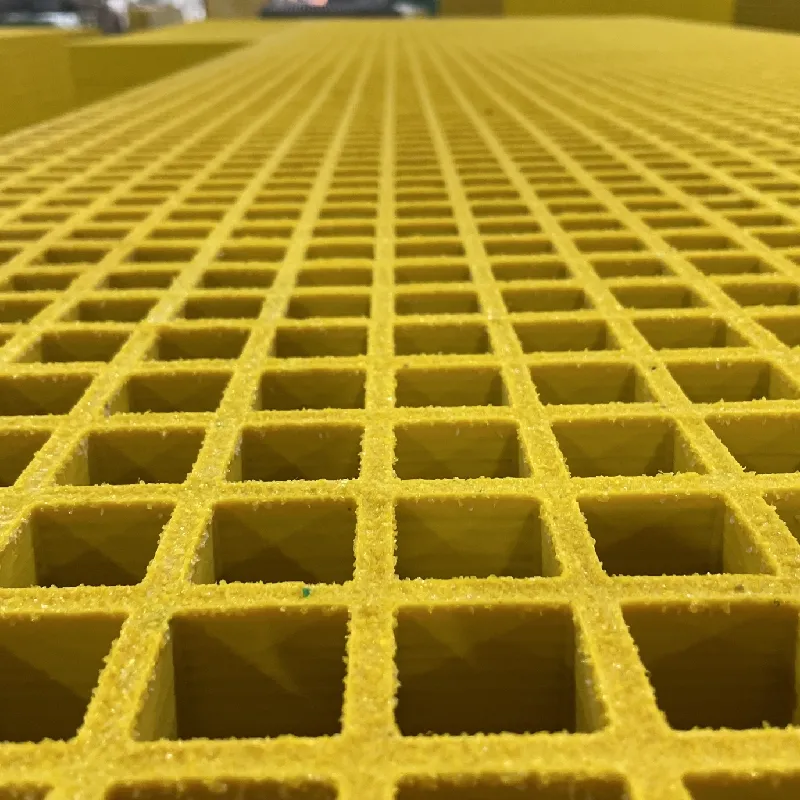

- Additives: UV inhibitors for outdoor stability, fire retardants, pigments for color, and anti-slip grit (silica or aluminum oxide) embedded on the top surface.

Manufacturing Processes:

-

Molded Grating:

- Mold Preparation: A pre-waxed or treated mold (often steel) is prepared to ensure easy release of the cured product.

- Layering: Continuous glass fiber rovings are laid in alternating layers within the mold, both lengthwise and crosswise, forming a grid pattern.

- Resin Pouring: A liquid resin mixture, catalyzed for curing, is poured over the glass fibers, saturating them completely.

- Compression & Curing (Casting): The mold is pressed, often with heat, to consolidate the materials and initiate the polymerization (curing) process. This creates a solid, one-piece panel with exceptional bi-directional strength.

- Demolding & Finishing: Once cured, the panel is removed, trimmed, and coated if required. Integral anti-slip grit is often applied during the molding process.

-

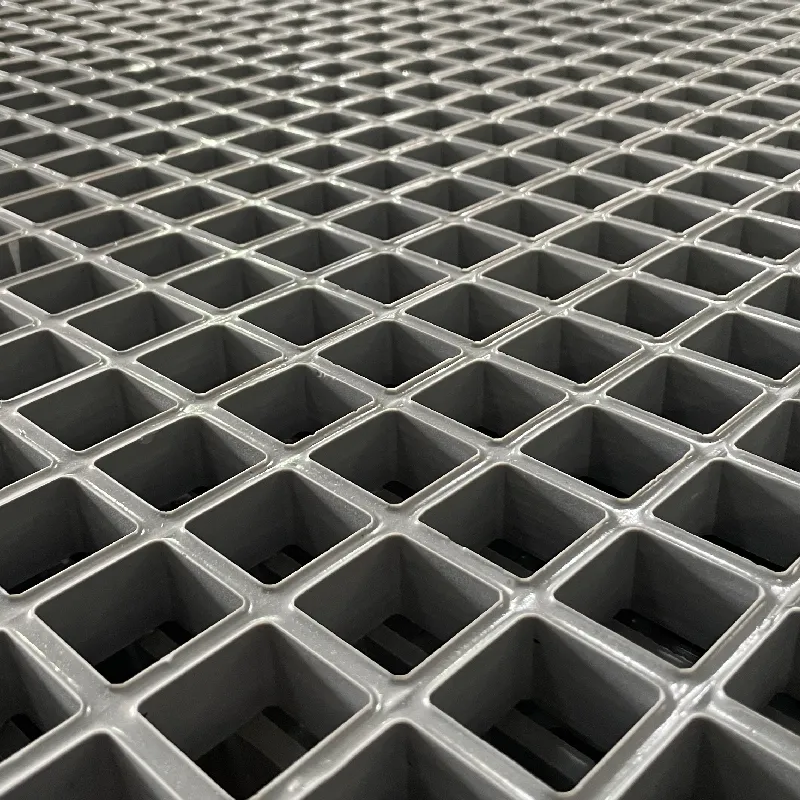

Pultruded Grating:

- Fiber Impregnation: Glass fiber rovings and mats are pulled through a resin bath, where they are fully impregnated with liquid resin.

- Shaping Die: The impregnated fibers are then pulled through a heated die that forms the desired profile (e.g., I-beams, T-bars, rods). This process is analogous to "pulling" (pultrusion) and "extrusion" for metals.

- Curing: As the material passes through the heated die, the resin polymerizes and cures, forming a rigid, continuous profile.

- Cutting & Assembly: The cured profiles are cut to length and then mechanically assembled (often using cross-rods) to create the grating panels.

Testing and Standards:

Quality assurance is critical. Products are rigorously tested according to international standards such as ISO (International Organization for Standardization) for quality management systems (e.g., ISO 9001), ASTM International (e.g., ASTM E84 for flame spread, ASTM D638 for tensile properties, ASTM D790 for flexural strength), and ANSI (American National Standards Institute) for safety and performance. These tests ensure load-bearing capacity, deflection limits, chemical resistance, UV stability, and fire rating, guaranteeing a service life often exceeding 25-30 years with minimal maintenance.

Target Industries and Advantages:

FRP grating's superior properties make it indispensable across various sectors:

- Petrochemical: Exceptional corrosion resistance to acids, alkalis, and solvents, ensuring safety and longevity in aggressive chemical processing areas.

- Metallurgy & Mining: Withstands abrasive conditions and corrosive agents present in mineral processing, enhancing worker safety through anti-slip surfaces.

- Water Supply & Drainage: Impervious to water, sewage, and chemical additives, ideal for treatment plants, pump stations, and marine environments, drastically reducing maintenance costs compared to steel.

- Energy & Power Generation: Non-conductive properties make it safe for electrical substations and power plants, preventing accidental electrocution. Its lightweight nature also contributes to energy saving during transport and installation.

In these scenarios, FRP grating demonstrates tangible advantages such as energy saving through lighter construction, reduced need for heavy lifting equipment, and remarkable corrosion resistance that eliminates the need for frequent painting or replacement, leading to significant lifecycle cost savings.

Technical Specifications: Focus on FRP Micro Mesh Grating

While standard FRP grating offers excellent performance, specific applications demand finer mesh sizes. FRP micro mesh grating is engineered with smaller openings, providing enhanced safety and superior load distribution for situations where small objects could fall through standard grating, or where continuous foot traffic requires a more comfortable walking surface. These smaller apertures also prevent tools and other equipment from falling through, minimizing trip hazards.

For instance, the Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating often features options for micro-mesh, combining the inherent advantages of FRP with a smaller open area. This particular product is designed for high-performance in various industrial settings, focusing on safety and durability.

Typical Specifications for High-Performance FRP Grating (e.g., Standard & Micro Mesh Options)

| Parameter | Standard Mesh FRP Grating | FRP Micro Mesh Grating |

|---|---|---|

| Resin Type (Common) | Isophthalic Polyester (General Purpose) | Isophthalic or Vinylester (Enhanced Chemical Resistance) |

| Fiberglass Content | Typically 30-35% | Typically 35-40% |

| Standard Panel Size | 1220x3660mm (4'x12'), 1000x3000mm | 1220x3660mm (4'x12'), 1000x3000mm |

| Standard Thicknesses | 25mm, 30mm, 38mm, 50mm | 25mm, 30mm, 38mm |

| Standard Mesh Size (Center to Center) | 38x38mm, 50x50mm | 19x19mm, 25x25mm (approx. 3/4"x3/4" or 1"x1") |

| Open Area | 60-70% | 40-50% |

| Weight (38mm thick) | Approx. 20-22 kg/sqm | Approx. 25-28 kg/sqm (higher resin content) |

| Fire Rating (ASTM E84) | Class 1 (Flame Spread Index < 25) | Class 1 (Flame Spread Index < 25) |

| Slip Resistance | Excellent (Concave or Grit Top) | Superior (Grit Top, smaller openings) |

| Deflection (max. load) | Engineered per span and load | Reduced deflection for equivalent load due to smaller mesh |

Versatile Application Scenarios for FRP Grating

The adaptability and robust performance of FRP grating allow it to excel in a multitude of industrial and commercial applications where conventional materials fail or incur prohibitive maintenance costs. Its unique combination of properties makes it ideal for challenging environments.

- Chemical Processing Plants: Ideal for walkways, platforms, and trench covers due to its exceptional resistance to acids, alkalis, and solvents. It prevents corrosion and ensures long-term structural integrity in environments where steel would rapidly deteriorate.

- Oil and Gas Facilities (Onshore & Offshore): Used for rig platforms, walkways, stairs, and mezzanines. Its non-corrosive nature and lightweight design are crucial for marine environments, reducing structural load and maintenance in salt-laden air.

- Water and Wastewater Treatment Plants: Preferred for clarifier walkways, filter media support, and aeration basins. FRP is impervious to chlorine, hydrogen sulfide, and other corrosive chemicals prevalent in these facilities, ensuring safety and operational continuity.

- Food and Beverage Production: Hygienic, easy to clean, and resistant to wash-down chemicals, FRP grating is suitable for processing areas, drainage covers, and elevated walkways, meeting strict sanitation requirements.

- Electrical Utilities & Data Centers: Its non-conductive property makes it safe for use around electrical equipment, substations, and as flooring in data centers where electromagnetic transparency is required.

- Mining and Mineral Processing: Resistant to abrasion and corrosion from slurry and harsh chemicals, used in flotation cells, leach pads, and processing areas.

- Architectural and Recreational: Increasingly utilized for aesthetic purposes in pedestrian bridges, tree grates, and decorative screens due to its design flexibility and various color options.

- Marine and Shipbuilding: Lightweight, corrosion-resistant, and non-slip, it's used for ship decks, gangways, and dock platforms, reducing overall vessel weight and improving safety.

In each of these scenarios, FRP grating significantly outperforms traditional materials by offering a safer, more durable, and more cost-effective solution over its entire lifecycle.

Unrivaled Technical Advantages of FRP Grating

The widespread adoption of FRP grating across diverse industries is fundamentally driven by its compelling array of technical advantages, which address critical operational challenges and deliver long-term economic benefits.

- Exceptional Corrosion Resistance: Unlike steel, FRP grating will not rust or corrode when exposed to harsh chemicals, saltwater, or acidic/alkaline environments. Different resin systems (e.g., Isophthalic, Vinylester, Phenolic) can be specified for resistance to virtually any corrosive agent, ensuring longevity and structural integrity without costly protective coatings or frequent replacement.

- High Strength-to-Weight Ratio: FRP is significantly lighter than steel, often by 60-80%, yet offers comparable or superior load-bearing capabilities. This facilitates easier and faster installation, reduces transportation costs, and places less stress on supporting structures.

- Superior Anti-Slip Properties: Most FRP grating comes with an integral concave or grit-top surface, providing excellent slip resistance even in wet, oily, or icy conditions. This drastically enhances worker safety, reducing the risk of falls and related injuries.

- Electrical and Thermal Non-Conductivity: FRP is non-conductive, making it ideal for applications near electrical equipment where protection against electrocution or arcing is crucial. It also offers low thermal conductivity, meaning it remains comfortable to touch in extreme hot or cold environments, unlike metal.

- Low Maintenance and Long Service Life: Due to its inherent resistance to corrosion, UV degradation, and impact, FRP grating requires virtually no maintenance (painting, galvanizing, or frequent repair). This leads to substantial lifecycle cost savings and minimal operational downtime.

- Impact Resistance: FRP has a higher strength-to-impact ratio than many traditional materials. It can absorb impact without permanent deformation, returning to its original shape, unlike metals that dent or bend.

- Fire Retardancy: Many FRP grating products are engineered with fire-retardant resins, meeting stringent fire safety standards like ASTM E84 Class 1, offering enhanced safety in critical applications.

- UV Resistance: Incorporated UV inhibitors protect against degradation from prolonged sun exposure, making FRP suitable for outdoor installations without becoming brittle or discolored.

- Ergonomic Comfort: The slight inherent resilience of FRP can reduce worker fatigue on standing platforms compared to rigid metallic surfaces.

These combined attributes position FRP grating as a strategically advantageous material choice for demanding industrial environments, offering not just a product, but a long-term solution for safety, efficiency, and cost-effectiveness.

Navigating Vendor Comparison Among FRP Grating Suppliers

Selecting the right frp grating suppliers is as crucial as selecting the material itself. The market offers a range of manufacturers, but not all provide the same level of quality, service, and technical support. A thorough vendor comparison goes beyond price, focusing on long-term value, reliability, and partnership capabilities.

Key Factors for Evaluation:

- Certifications: Look for ISO 9001 for quality management, ASTM standards compliance, and potentially third-party verifications for specific performance metrics (e.g., fire ratings).

- Product Range and Customization: A reputable supplier should offer a wide array of resin systems, mesh configurations (including micro mesh), panel sizes, and colors, along with the capability for tailored solutions.

- Technical Support and Engineering Expertise: Access to experienced engineers who can assist with load calculations, design specifications, and installation guidance is invaluable.

- Reputation and Case Studies: Evaluate the supplier's track record, customer testimonials, and detailed case studies demonstrating successful project implementations.

- Lead Times and Logistics: The ability to meet project deadlines and efficiently manage global logistics is critical for large-scale industrial projects.

- Warranty and After-Sales Service: Clear warranty terms and responsive after-sales support reflect a supplier's confidence in their product and commitment to customer satisfaction.

Comparison of Typical FRP Grating Supplier Attributes

| Feature/Attribute | Tier 1 (Premium/Specialized) | Tier 2 (Standard/General Purpose) |

|---|---|---|

| Product Quality & Certifications | ISO 9001, ASTM-compliant, extensive third-party testing, specific industry certifications (e.g., DNV, ABS) | ISO 9001, basic ASTM compliance, in-house quality control |

| Resin Systems Offered | Orthophthalic, Isophthalic, Vinylester, Phenolic, Custom Blends | Mainly Orthophthalic, Isophthalic |

| Customization Capability | Full engineering support for custom sizes, shapes, colors, resin mixes, fabrication services | Limited customization, standard panel cutting |

| Technical Support & Expertise | Dedicated engineering team, design assistance, on-site consultation, detailed data sheets | Basic product data, general application advice |

| Lead Time (Standard Products) | Typically 2-4 weeks (dependent on order size/complexity) | Typically 3-6 weeks |

| Warranty | Comprehensive, 5-10 years on manufacturing defects and performance | Standard, 1-3 years on manufacturing defects |

| Pricing Structure | Higher initial cost, justified by superior performance, customization, and lifecycle value | Competitive initial cost, potentially higher long-term maintenance/replacement costs |

Customized Solutions for Unique Industrial Demands

While standard FRP grating solutions cover a wide range of applications, many industrial projects present unique challenges that necessitate tailored approaches. Leading frp grating suppliers distinguish themselves through their ability to provide comprehensive customized solutions, ensuring that the grating precisely meets the specific operational, environmental, and structural requirements of a given project.

Customization extends beyond mere panel cutting to size. It encompasses:

- Resin System Selection: Tailoring the resin matrix (e.g., specific grades of vinylester for extreme chemical resistance, phenolic for high fire performance) to match the exact chemical exposure, temperature, and fire rating requirements of the application.

- Custom Mesh Configurations: Designing non-standard mesh sizes or patterns for specialized filtration, light penetration, or aesthetic purposes, including unique micro mesh requirements.

- Panel Dimensions and Thicknesses: Manufacturing panels in specific, non-standard lengths, widths, or thicknesses to optimize load-bearing capacity, span capabilities, or to fit existing structures perfectly, minimizing waste and installation time.

- Surface Finishes: Offering various anti-slip finishes (grit, concave, smooth, checkered plate) and color options to match safety standards, branding, or aesthetic preferences.

- Fabrication and Assembly: Providing pre-fabricated sections, integrated stair treads, ladders, or complete structural assemblies with cut-outs for pipes or equipment, ready for immediate installation. This reduces on-site labor and potential errors.

- Load and Deflection Engineering: Collaborating with clients to engineer grating solutions that meet precise load-bearing and deflection specifications, ensuring optimal performance and safety under specific operational conditions.

This level of customization ensures that clients receive not just a product, but a precisely engineered solution that delivers maximum efficiency, safety, and longevity, often leading to significant long-term cost savings.

Real-World Application Case Studies

The practical benefits of FRP grating are best illustrated through successful deployments in demanding industrial environments. These case studies highlight the material's ability to solve complex engineering and operational challenges.

Case Study 1: Chemical Plant Walkways in a Corrosive Acid Environment

A major sulfuric acid production facility faced persistent issues with steel walkways and platforms corroding rapidly, requiring constant repair and replacement every 2-3 years. This led to significant downtime, high maintenance costs, and safety risks. The facility implemented FRP molded grating made with vinylester resin.

- Challenge: Severe corrosion from sulfuric acid fumes and spills, leading to structural degradation and safety hazards.

- Solution: Installation of 38mm thick, 38x38mm mesh Vinylester FRP grating with a grit top surface.

- Results: After 10 years, the FRP grating showed no signs of corrosion or degradation, drastically reducing maintenance costs by over 80% and eliminating safety concerns. The lightweight nature also simplified installation. Customer feedback highlighted improved worker confidence due to the stable and non-slip surfaces.

Case Study 2: Offshore Oil Rig Helideck and Platform Flooring

An offshore exploration platform needed a reliable, lightweight, and non-corrosive flooring solution for its helideck and various work platforms, exposed to constant saltwater spray and high winds. Traditional steel grating required frequent galvanizing and coating.

- Challenge: Extreme marine corrosion, heavy structural loads, and need for superior slip resistance under all weather conditions, coupled with weight restrictions.

- Solution: Pultruded FRP grating with an isophthalic resin system and an aggressive grit-top surface. Specialized bonding and fastening systems were used to secure panels.

- Results: The FRP grating delivered a 65% weight reduction compared to steel, leading to reduced structural stress on the rig. Its non-corrosive properties eliminated ongoing maintenance, and the superior grit surface significantly enhanced safety during helicopter landings and personnel movement, even in foul weather. The project delivered a 15-year estimated service life without major intervention.

Frequently Asked Questions (FAQ) about FRP Grating

Q1: What are the primary advantages of FRP grating over steel grating?

A1: FRP grating offers superior corrosion resistance, is significantly lighter (60-80% lighter), non-conductive (both electrically and thermally), and requires virtually no maintenance. It also often features better anti-slip properties and excellent impact resistance. These factors contribute to lower lifecycle costs and enhanced safety.

Q2: How do I choose the correct resin system for my application?

A2: The resin system is critical for chemical resistance. Orthophthalic polyester is suitable for general-purpose applications. Isophthalic polyester offers better resistance to a wider range of chemicals. Vinylester provides superior corrosion resistance for highly aggressive environments (e.g., strong acids, alkalis, high temperatures). Phenolic resins are used where high fire retardancy and low smoke emission are paramount. Consulting with experienced frp grating suppliers is recommended to match the resin to your specific chemical exposure.

Q3: Is FRP grating fire resistant?

A3: Many FRP grating products are manufactured with fire-retardant additives in the resin, achieving Class 1 flame spread rating per ASTM E84. For applications requiring extreme fire resistance and low smoke, phenolic FRP grating is available, specifically designed to perform in high-temperature fire situations.

Q4: Can FRP grating be cut or fabricated on-site?

A4: Yes, FRP grating can be cut and fabricated on-site using standard power tools equipped with diamond or carbide-tipped blades. It is essential to wear appropriate PPE, including dust masks, safety glasses, and gloves, to prevent inhalation of fiberglass dust. Edges should be sealed with a compatible resin to maintain corrosion resistance. Many suppliers also offer factory fabrication services for precise, pre-cut panels.

Q5: What is the typical lead time for FRP grating orders?

A5: Lead times vary based on the type of grating, order quantity, customization requirements, and the supplier's inventory levels. For standard products, lead times typically range from 2 to 6 weeks. Custom or large volume orders may require longer lead times, usually between 6 to 12 weeks. It is always best to confirm lead times directly with your chosen supplier at the quotation stage.

Lead Time, Fulfillment, and Warranty Commitments

For B2B procurement, understanding the logistics and support structure is as vital as the product itself. Reputable frp grating suppliers prioritize transparent communication regarding lead times, efficient fulfillment processes, and robust warranty commitments to build client trust.

Lead Time & Fulfillment:

- Standard Products: For in-stock standard mesh or micro mesh FRP grating panels, lead times can be as short as 2-3 weeks for fabrication and shipping preparation.

- Custom Orders: Projects requiring specific resin formulations, custom colors, unique panel sizes, or complex fabrication may have lead times ranging from 6 to 12 weeks, depending on the complexity and volume. We work closely with clients to establish realistic timelines.

- Fulfillment Process: Orders are processed through a meticulous system from quotation to delivery. This includes material sourcing, manufacturing, quality control checks, secure packaging, and coordinated logistics (road, sea, or air freight) to ensure timely and safe delivery to the project site. Real-time tracking information is provided where available.

Warranty Commitments:

We stand behind the quality and durability of our FRP grating products. Our standard warranty covers manufacturing defects and material performance for a period of 5 years from the date of purchase, under normal use and recommended installation conditions. This warranty ensures that the grating will maintain its structural integrity, chemical resistance, and anti-slip properties as specified. Extended warranty options may be available for specific high-value projects or extreme applications upon consultation.

Dedicated Customer Support and After-Sales Service

Exceptional customer support is integral to the value proposition of leading frp grating suppliers. Our commitment extends beyond product delivery to providing comprehensive support throughout the lifecycle of your project and beyond.

- Pre-Sales Consultation: Our team of experienced engineers and technical sales representatives offers expert advice on product selection, resin chemistry, load calculations, and design optimization to ensure the best solution for your specific application.

- Technical Documentation: Provision of detailed product data sheets, installation guides, chemical resistance charts, and compliance certifications (e.g., ISO, ASTM reports).

- Project Management: Dedicated account managers oversee your order from initial inquiry through to post-delivery, ensuring seamless communication and problem resolution.

- After-Sales Support: Our support team is readily available to address any post-installation queries, assist with maintenance best practices, or provide guidance on future expansion or modification of your FRP grating systems.

- Global Reach, Local Service: With established distribution networks, we combine global manufacturing capabilities with responsive local support to serve our international clientele effectively.

We are committed to building long-term partnerships by providing not just high-quality FRP products, but also the expertise and support needed for your project's success.

Conclusion

FRP grating stands as a testament to advanced material science, offering a compelling blend of durability, safety, and economic advantages over traditional industrial materials. Its unparalleled resistance to corrosion, high strength-to-weight ratio, non-conductive properties, and minimal maintenance requirements make it an indispensable asset across a multitude of challenging sectors. For B2B decision-makers, choosing the right supplier is paramount, focusing on expertise, comprehensive product offerings, customization capabilities, and robust after-sales support. By meticulously evaluating these factors, industries can harness the full potential of FRP grating, leading to safer, more efficient, and more sustainable operational environments. The long-term benefits in terms of reduced lifecycle costs and enhanced operational reliability underscore FRP grating's position as a cornerstone of modern industrial infrastructure.

References

- ASTM International Standards. ASTM D638: Standard Test Method for Tensile Properties of Plastics; ASTM D790: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials.

- Fiberglass Grating Manufacturers Council (FGMC) of the American Composites Manufacturers Association (ACMA). Composites and their applications in various industries.

- ISO (International Organization for Standardization). ISO 9001: Quality management systems – Requirements.

- ACI Committee 440. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute, 2017.

- Bank, L. C. Composites for Construction: Structural Design with FRP Materials. John Wiley & Sons, 2006.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025