loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable FRP Profiles: Lightweight, Strong & Corrosion Resistant

The Ascendance of Advanced Composites: Understanding frp profiles

In the rapidly evolving landscape of modern construction and industrial applications, the demand for materials that offer unparalleled strength, durability, and resistance to environmental stressors has never been higher. Traditional materials, while robust, often fall short in specialized environments where corrosion, conductivity, or weight are critical concerns. This is where Fiberglass Reinforced Polymer (frp profiles) emerge as a transformative solution, redefining structural integrity and operational efficiency across diverse sectors.

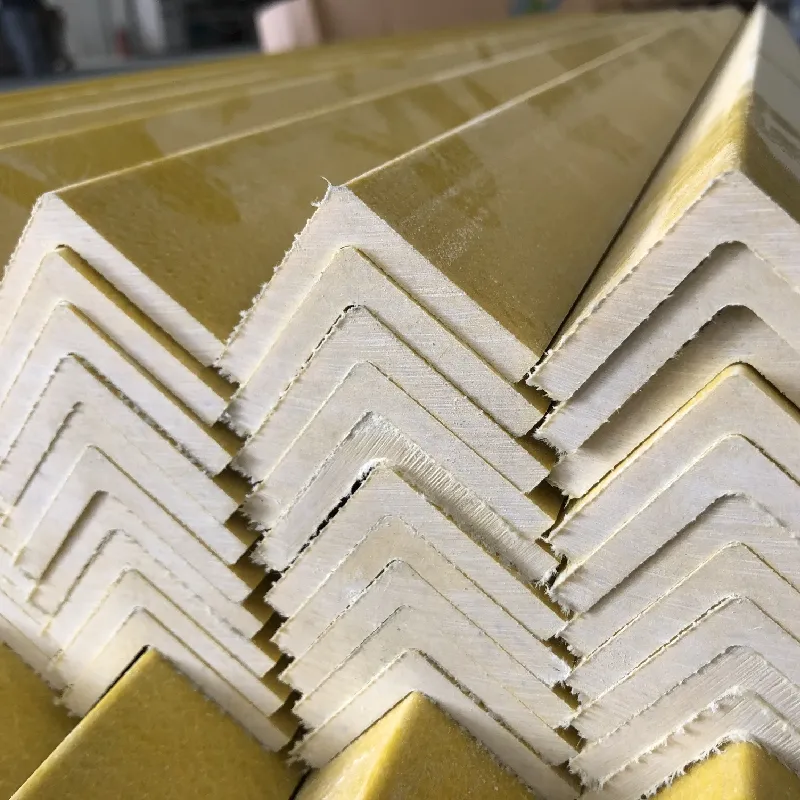

FRP composites are engineered materials that combine the strength of fiberglass reinforcements with the resilience of polymer resins. Through advanced manufacturing processes, these materials are transformed into various profiles—I-beams, channels, angles, tubes, and more—each meticulously designed for specific structural or functional roles. Their unique properties address complex engineering challenges, from enhancing safety in hazardous environments to extending the service life of critical infrastructure.

This article delves into the intricate world of frp profiles, exploring their manufacturing intricacies, technical superiority, broad application spectrum, and the compelling advantages they offer over conventional materials. We will also examine key industry trends, technical specifications, and the crucial factors for selecting the right vendor and solution, underpinned by real-world data and case studies.

Industry Trends and Market Outlook for FRP Composites

The global FRP composites market is experiencing robust growth, driven by increasing adoption in construction, infrastructure, automotive, wind energy, and aerospace sectors. According to market research by Grand View Research, the global FRP composites market size was valued at USD 106.3 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2024 to 2030. This expansion is largely attributed to the growing preference for lightweight, high-strength, and corrosion-resistant materials.

- Sustainable Solutions: A significant trend is the increasing focus on sustainability. FRP products, with their long service life and reduced need for maintenance, contribute to lower lifecycle costs and a smaller environmental footprint compared to traditional materials that often require frequent replacement or intensive protective coatings.

- Infrastructure Modernization: Governments worldwide are investing heavily in infrastructure projects. frp profiles are ideal for bridge decks, retaining walls, marine structures, and utility poles due to their resistance to water, chemicals, and extreme weather, significantly extending the lifespan of critical assets.

- Renewable Energy Expansion: The wind energy sector, in particular, relies heavily on FRP for wind turbine blades, where the material’s light weight and high fatigue resistance are indispensable for efficient energy generation.

- Advanced Manufacturing Techniques: Continuous innovation in manufacturing processes, such as advanced pultrusion and resin transfer molding, is enabling the production of more complex shapes and higher-performance FRP products, further broadening their applicability.

Understanding FRP Pultruded Profiles: The Manufacturing Process

The creation of high-quality frp profiles primarily utilizes the pultrusion process, a continuous manufacturing method that ensures consistent quality and allows for the production of complex, constant cross-sectional shapes. This process is critical to imparting the desired mechanical and chemical properties to the final product.

Process Flow: Pultrusion of FRP Profiles

- Reinforcement Handling: Continuous fibers (such as fiberglass roving or mats, e.g., E-glass or S-glass for higher strength) are pulled from creels. These fibers provide the primary structural integrity. In some cases, carbon fibers or aramid fibers may be incorporated for enhanced properties.

- Resin Impregnation: The dry fibers are saturated with a liquid resin mixture. This resin, often polyester, vinyl ester, epoxy, or phenolic, contains catalysts, pigments, and other additives tailored for specific application requirements (e.g., UV inhibitors, flame retardants). Vinyl ester resins are frequently used for superior corrosion resistance in chemical environments.

- Pre-forming and Shaping: The saturated fibers are then guided through a pre-forming guide that shapes them into the desired profile before entering the heated die. This step removes excess resin and consolidates the material.

- Curing in a Heated Die: The formed, resin-impregnated material is pulled through a heated steel die. Inside the die, the heat triggers a polymerization reaction in the resin, causing it to harden and cure. This is where the profile achieves its final rigid shape and mechanical properties. The die temperature and pull speed are meticulously controlled.

- Pulling and Cutting: Continuous pulling mechanisms (grippers or caterpillars) draw the cured profile from the die. An automatic cut-off saw then cuts the continuous profile to the specified lengths.

- Post-processing & Quality Control: Finished profiles undergo rigorous quality checks, including dimensional accuracy, visual inspection, and mechanical testing (e.g., tensile strength, flexural modulus, compressive strength as per ASTM D638, ASTM D790, ASTM D695). Products may also be tested against specific industry standards like ISO 9001 for quality management or ANSI standards for structural applications. Typical service life for high-quality FRP profiles often exceeds 50 years even in harsh environments, vastly surpassing traditional materials.

Figure 1: Illustration of the FRP Pultrusion Process.

The material composition significantly impacts the performance of frp profiles. For example, the High Strength FRP Pultruded Profile Fiberglass I Beam for Construction mentioned is likely engineered with high-modulus fiberglass roving and a robust resin system (e.g., isophthalic polyester or vinyl ester) to provide exceptional load-bearing capacity and corrosion resistance suitable for demanding structural roles in petrochemical, metallurgy, and water supply & drainage industries. Advantages in these scenarios include energy saving through reduced maintenance and superior corrosion resistance, minimizing downtime and replacement costs.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of frp profiles is crucial for engineers and procurement specialists. These parameters dictate the suitability of a profile for a given application, ensuring structural integrity and longevity. Key performance indicators include mechanical properties, physical properties, and chemical resistance.

Typical Product Specification: High Strength FRP I-Beam

| Property | Test Method | Value (Typical) | Unit |

|---|---|---|---|

| Tensile Strength (Longitudinal) | ASTM D638 | ≥ 200 | MPa |

| Flexural Strength (Longitudinal) | ASTM D790 | ≥ 250 | MPa |

| Flexural Modulus (Longitudinal) | ASTM D790 | ≥ 20 | GPa |

| Compressive Strength (Longitudinal) | ASTM D695 | ≥ 150 | MPa |

| Density | ASTM D792 | 1.8 - 2.0 | g/cm³ |

| Coefficient of Thermal Expansion (Longitudinal) | ASTM D696 | 10 x 10-6 - 20 x 10-6 | m/m/°C |

| Dielectric Strength | ASTM D149 | ≥ 40 | kV/mm |

Note: Values are typical and can vary based on specific resin systems, fiber architecture, and manufacturing variations. Always refer to specific product datasheets for certified values.

These values demonstrate the superior engineering capabilities of FRP. For instance, a high flexural modulus indicates excellent stiffness, crucial for structural beams. The low coefficient of thermal expansion ensures dimensional stability across temperature fluctuations, preventing material fatigue and structural failure in varied climatic conditions. Furthermore, the high dielectric strength underscores its utility in electrical insulation applications, making it safe for live working environments.

Key Technical Advantages of FRP Profiles

The adoption of frp profiles is driven by a compelling suite of advantages that address the limitations of traditional materials like steel, aluminum, and timber. These benefits contribute significantly to reduced lifecycle costs, enhanced safety, and improved operational efficiency.

- Exceptional Corrosion Resistance: FRP is inherently resistant to a wide range of corrosive chemicals, acids, alkalis, saltwater, and atmospheric exposure. Unlike metals, it does not rust or corrode, making it ideal for applications in chemical plants, wastewater treatment facilities, marine environments, and coastal infrastructure.

- High Strength-to-Weight Ratio: FRP profiles offer comparable strength to steel at a fraction of the weight (typically 1/4 the weight of steel). This significantly reduces transportation costs, simplifies installation, and lessens the load on supporting structures, enabling longer spans and lighter designs without compromising structural integrity.

- Electrical Non-Conductivity: As a dielectric material, FRP does not conduct electricity, providing superior electrical insulation. This makes it a preferred choice for electrical infrastructure, utility applications, and environments where safety from electrical hazards is paramount.

- Thermal Insulation Properties: FRP possesses low thermal conductivity, making it an excellent insulator. This property helps maintain temperature stability, reduces heat transfer, and can contribute to energy efficiency in buildings and industrial processes.

- Electromagnetic Transparency: FRP is non-magnetic and transparent to radio frequencies and electromagnetic fields. This is crucial for sensitive applications like MRI rooms, radar facilities, telecommunications infrastructure, and other environments where metallic interference must be avoided.

- Low Maintenance and Long Service Life: Due to its resistance to corrosion, rot, insect damage, and UV degradation, FRP requires minimal maintenance over its extended service life, which can exceed 50 years. This translates into substantial cost savings over the material's lifetime.

- Impact Resistance: FRP exhibits good impact absorption properties, resisting permanent deformation from sudden impacts, making it resilient in dynamic environments.

Diverse Application Scenarios

The versatility of frp profiles allows for their deployment across a myriad of industries, solving persistent engineering challenges and offering superior performance compared to traditional materials.

Target Industries and Typical Uses:

- Petrochemical and Chemical Processing: Ideal for platforms, walkways, handrails, structural supports for tanks and pipes, and cooling towers, where exposure to highly corrosive chemicals and hazardous environments necessitates non-corrosive and non-conductive materials. Energy saving is achieved through reduced downtime and replacement.

- Water and Wastewater Treatment: Used extensively for clarifier components, media supports, weir plates, scum baffles, grating, and structural elements in treatment plants. Its corrosion resistance to chlorine, acids, and alkalis ensures long-term integrity.

- Infrastructure and Civil Engineering: Applications include bridge decks, pedestrian bridges, seawalls, docks, retaining wall systems, and noise barriers. The lightweight nature aids in quick installation and reduces foundation requirements.

- Power Generation and Utilities: Employed in power plants for substation structures, utility poles, trench covers, and structural supports where electrical insulation and corrosion resistance are critical for safety and operational continuity.

- Transportation: Used in railway crossing panels, platform structures, and increasingly in automotive and aerospace components for weight reduction and increased fuel efficiency.

- Mining and Metallurgy: For structures within processing plants exposed to aggressive chemicals and harsh conditions, such as support beams for conveyor systems or platforms in refining operations.

Figure 2: FRP Profiles in a corrosive industrial setting, demonstrating robust performance.

Vendor Comparison and Selection Criteria

Choosing the right supplier for frp profiles is paramount to the success and longevity of any project. A thorough evaluation process should consider several key factors beyond just price.

Key Selection Criteria:

- Manufacturing Expertise & Technology: Assess the vendor’s experience in pultrusion and their technological capabilities. Are they using advanced machinery? Do they have robust quality control processes?

- Material Quality & Customization: Can they provide detailed material specifications? Do they offer a range of resin systems (e.g., isophthalic, vinyl ester, phenolic) and reinforcement types to meet specific chemical resistance, fire retardancy, or strength requirements?

- Certifications & Standards Compliance: Verify compliance with international standards such as ISO 9001 (Quality Management), ASTM (American Society for Testing and Materials) for product performance, and local building codes. Certifications from recognized bodies provide assurance of quality and safety.

- Technical Support & Engineering Services: A reliable vendor should offer pre-sale consultation, engineering design assistance, and post-sale support to ensure optimal product integration and performance.

- Track Record & References: Review their portfolio of completed projects, customer testimonials, and years of service in the industry. Partnership with well-known clients often indicates reliability.

- Lead Time & Logistics: Evaluate their production capacity and logistics capabilities to meet project timelines and delivery requirements efficiently.

FRP vs. Traditional Materials: A Performance Comparison

| Property | FRP (Pultruded) | Steel (Structural) | Aluminum (Alloy) |

|---|---|---|---|

| Density (g/cm³) | 1.8 - 2.0 | 7.85 | 2.7 |

| Corrosion Resistance | Excellent | Poor (requires coating) | Good (but susceptible to galvanic) |

| Electrical Conductivity | Non-conductive | Conductive | Conductive |

| Thermal Conductivity | Low (Insulator) | High (Conductor) | High (Conductor) |

| Electromagnetic Transparency | Transparent | Opaque | Opaque |

| Maintenance | Very Low | High (painting, rust removal) | Moderate |

Source: Comparative analysis based on typical material properties.

This comparison clearly illustrates the technical superiority of FRP in environments where corrosion, weight, and electrical properties are critical. While initial material costs might sometimes be higher, the long-term savings from reduced maintenance, extended service life, and specific operational advantages often result in a significantly lower total cost of ownership for frp profiles.

Customized FRP Solutions

One of the most compelling advantages of working with specialized manufacturers of frp profiles is the ability to develop customized solutions. While standard profiles meet many needs, complex projects often require tailored designs to achieve optimal performance and integration.

Customization extends beyond mere dimensions. It involves selecting the appropriate resin system (e.g., highly chemical-resistant vinyl ester for aggressive acids, flame-retardant phenolic for fire-critical areas), fiber reinforcement type and orientation (e.g., E-glass for general use, S-glass for higher strength), and specific additives (e.g., UV inhibitors for outdoor exposure, anti-static agents for hazardous areas). This allows for profiles optimized for specific load-bearing capacities, environmental exposures, and safety requirements. Expert manufacturers collaborate with clients from conceptual design through to prototyping and full production, ensuring the bespoke solution precisely fits the application's unique demands and provides maximum value.

Real-World Application Case Studies

The practical benefits of frp profiles are best illustrated through successful applications that have demonstrated tangible improvements over traditional materials.

Case Study 1: Chemical Plant Walkways and Structures

- Challenge: A major petrochemical facility faced constant corrosion and degradation of steel walkways, platforms, and stairways due to exposure to aggressive acids and alkalis. Frequent maintenance, including sandblasting and repainting, led to significant operational downtime and high costs.

- Solution: The facility implemented structural systems built entirely from FRP pultruded profiles (I-beams, channels, angles, and grating) made with a vinyl ester resin system for maximum chemical resistance.

- Results: Over a 10-year period, the FRP structures showed virtually no signs of corrosion or degradation. Maintenance requirements dropped by over 90%, eliminating costly shutdowns for repair. The lightweight nature of FRP also simplified installation and reduced overall project timelines by 25%.

Case Study 2: Wastewater Treatment Plant (WWTP) Support Structures

- Challenge: Steel and concrete components within aeration tanks and clarifiers at a municipal WWTP were failing prematurely due to constant immersion in chemically aggressive wastewater and exposure to corrosive gases (e.g., hydrogen sulfide).

- Solution: The plant replaced corroded steel supports, baffles, and tank covers with FRP pultruded profiles and panels. The FRP material used was specifically formulated with an isophthalic polyester resin for excellent resistance to the chemical cocktail present in wastewater.

- Results: The FRP components demonstrated superior longevity, with no visible signs of deterioration after 15 years, significantly extending the operational life of the structures. The non-conductive nature also improved safety for maintenance personnel working near electrical equipment. The plant achieved substantial cost savings from reduced replacement frequency and maintenance.

Figure 3: FRP structures providing durable solutions in challenging industrial settings.

Ensuring Trust: Certifications, Warranty, and Support

For B2B buyers, trust is built on demonstrable quality, reliable service, and strong commitments. Reputable suppliers of frp profiles adhere to stringent quality standards and provide comprehensive customer support.

Authoritativeness and Certifications:

Our products, including the High Strength FRP Pultruded Profile Fiberglass I Beam, are manufactured under strict quality management systems, often certified to ISO 9001:2015. We adhere to relevant ASTM standards for mechanical properties and performance, ensuring that our products meet or exceed industry benchmarks. Our commitment to quality is further evidenced by partnerships with leading engineering firms and contractors across various sectors, and our extensive experience spans over a decade in delivering advanced composite solutions.

Lead Time and Fulfillment:

Standard FRP profiles typically have a lead time of 3-6 weeks, depending on order volume and specific customization requirements. For urgent projects, expedited manufacturing and delivery options can be discussed with our sales team. Our robust production capacity and efficient logistics network ensure timely fulfillment and delivery to global destinations.

Warranty Commitments:

We stand behind the quality of our frp profiles with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. Typical structural warranties range from 5 to 10 years, reflecting our confidence in the product's durability and performance. Specific warranty terms will be provided with each quotation.

Customer Support:

Our dedicated customer support team and technical experts are available to assist with product selection, engineering design, installation guidance, and any post-sales inquiries. We offer technical datasheets, installation manuals, and on-site support if required, ensuring a seamless experience from inquiry to project completion. Our goal is to forge long-term partnerships built on trust and mutual success.

Frequently Asked Questions (FAQ) about FRP Profiles

- Q1: Are FRP profiles fire resistant?

- A1: While standard FRP is not inherently fireproof, it can be manufactured with special fire-retardant resins and additives to achieve specific fire ratings, such as ASTM E84 Class 1 flame spread. These specialized profiles are suitable for applications where fire safety is a critical concern, such as in tunnels, mass transit systems, and certain industrial facilities.

- Q2: How do FRP profiles compare in cost to steel?

- A2: The initial material cost of FRP can sometimes be higher than steel. However, when considering the total lifecycle cost, including factors like reduced installation labor (due to lighter weight), eliminated maintenance (no painting, no rust removal), and significantly extended service life in corrosive environments, FRP often proves to be a more cost-effective solution over the long term.

- Q3: Can FRP profiles be machined or cut on-site?

- A3: Yes, FRP profiles can be cut, drilled, and machined on-site using standard carpentry tools with carbide or diamond-tipped blades. It is essential to use proper dust collection and personal protective equipment (PPE) as FRP dust can be an irritant. We also offer pre-fabrication services to minimize on-site work.

- Q4: What is the load-bearing capacity of FRP I-beams?

- A4: The load-bearing capacity varies significantly depending on the profile dimensions, wall thickness, resin system, and fiber reinforcement. For instance, a High Strength FRP Pultruded Profile Fiberglass I Beam for Construction can offer substantial load capacities suitable for structural applications. Detailed load tables and engineering calculations are available for specific products to ensure safe and compliant designs.

- Q5: Are FRP profiles UV resistant for outdoor applications?

- A5: Yes, most modern frp profiles are manufactured with UV inhibitors integrated into the resin system and/or with a UV-resistant surface veil. This provides excellent resistance to degradation from sunlight exposure, making them highly suitable for long-term outdoor applications without significant fading or loss of mechanical properties.

Conclusion

The paradigm shift towards advanced materials is clearly demonstrated by the increasing adoption of frp profiles. These engineered composites offer a compelling combination of lightweight strength, unparalleled corrosion resistance, electrical non-conductivity, and minimal maintenance requirements, making them indispensable for critical infrastructure and demanding industrial applications. By understanding their manufacturing process, technical specifications, and diverse advantages, industries can make informed decisions that lead to safer, more durable, and ultimately more cost-effective solutions. As global demands for sustainable and resilient infrastructure continue to grow, FRP profiles are poised to play an even more pivotal role in shaping the future of construction and engineering.

References

- Grand View Research. (2024). FRP Composites Market Size, Share & Trends Analysis Report By Fiber Type (Carbon, Glass, Basalt, Aramid), By Resin (Polyester, Vinyl Ester, Epoxy), By Application, By Region, And Segment Forecasts, 2024 - 2030.

- ASTM International. Annual Book of ASTM Standards, Section 8: Plastics, Volume 08.01, 08.02, 08.03.

- Bank, L. C. (2006). Composites for Construction: Structural Design with FRP Materials. John Wiley & Sons.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025