loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Holiday Special Offers: Discounted FRP Fiberglass Gratings & Grates

Industry Overview and Market Trends

As the global industrial and construction sectors increasingly prioritize corrosion resistance and structural longevity, the demand for high-performance materials like Holiday Special Offers GRP FRP Gratings Fiberglass Grates has witnessed remarkable growth. Current market analysis reveals a projected CAGR of 8.9% for fiberglass reinforced plastic (FRP) solutions from 2023 to 2030, driven largely by infrastructure modernization programs worldwide.

Modern industrial applications demand materials that outperform traditional alternatives in challenging environments. GRP FRP gratings uniquely address this need through their exceptional chemical resistance, anti-slip properties, and structural integrity. Particularly in harsh environments such as chemical processing plants, offshore installations, and wastewater treatment facilities, these composite solutions deliver unparalleled safety and durability.

- Materials Today (2023), Advanced Composites in Industrial Applications

As we approach the holiday season, Zhaojia Composites Co., Ltd is proud to offer exclusive promotions on our premium Holiday Special Offers GRP FRP Gratings Fiberglass Grates product range - delivering unprecedented value for infrastructure managers, engineers, and procurement specialists. Our technologically advanced products undergo rigorous quality testing and meet international standards including ASTM D635, ASTM E84, and BS EN ISO 14125 certifications.

Technical Specifications and Key Benefits

The engineering excellence behind our Holiday Special Offers GRP FRP Gratings Fiberglass Grates translates into tangible performance advantages. Our proprietary manufacturing process ensures uniform resin distribution and optimal fiber orientation, resulting in exceptional mechanical properties that remain consistent throughout the structure.

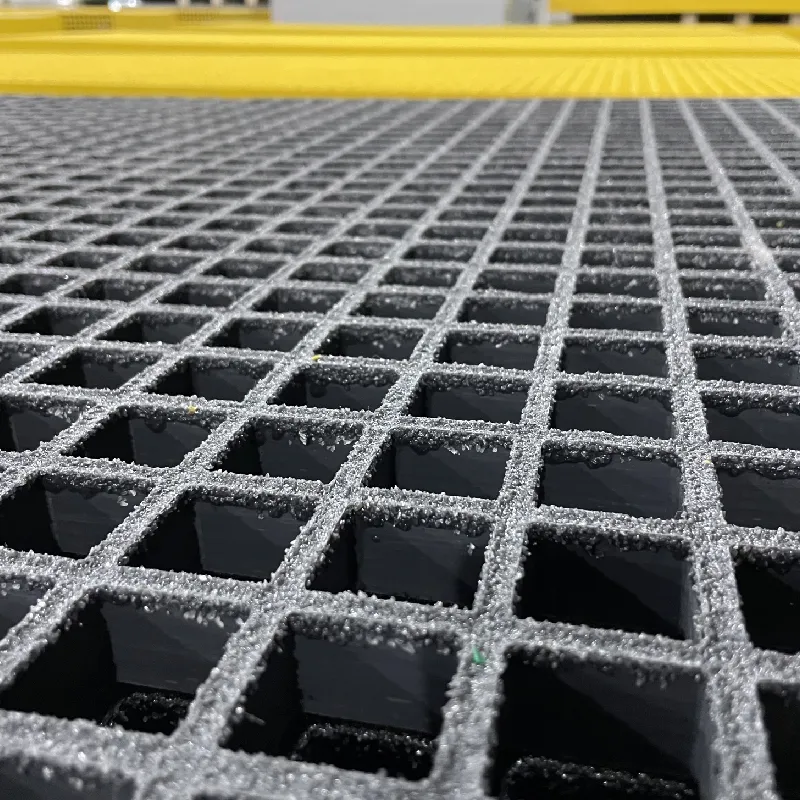

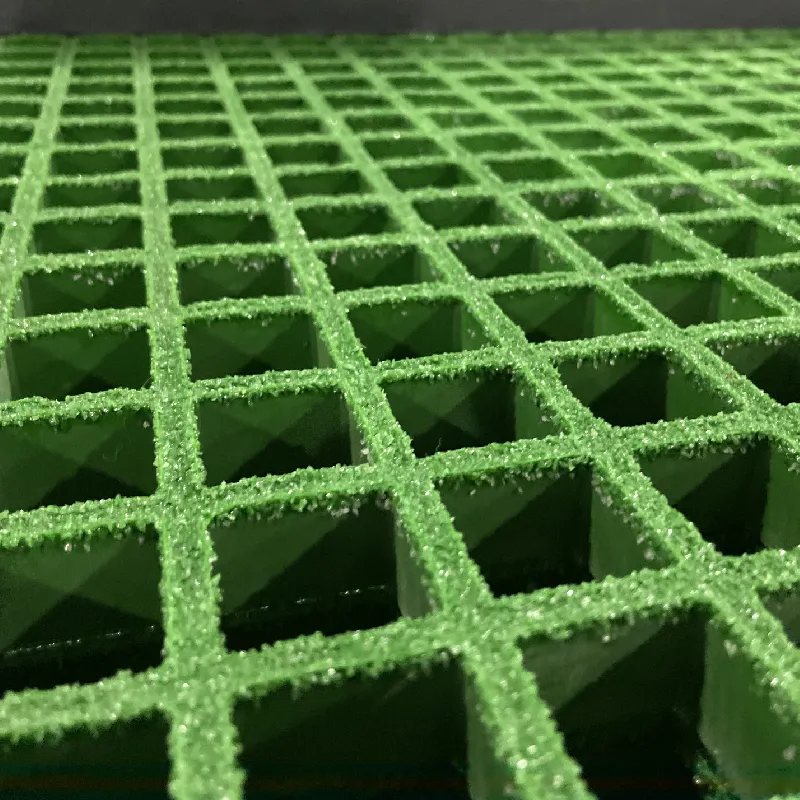

Differentiated surface treatments provide enhanced functionality across applications. Resin-rich surfaces optimize chemical resistance for splash zones in chemical processing plants, while specialized grit coatings offer critical anti-slip properties for offshore platforms and pedestrian walkways. Our R&D team has developed novel hybrid formulations that extend the temperature tolerance range to -60°C to +150°C without compromising structural integrity.

Technical Specifications Comparison

| Parameter | Standard FRP Grating | ZJ Mini-Mesh | ZJ Micro-Mesh | Carbon Steel | Aluminum |

|---|---|---|---|---|---|

| Load Capacity (PSF) | 300-600 | 450-900 | 600-1200 | 300-500 | 250-400 |

| Weight (lbs/sq ft) | 2.3-4.7 | 1.8-3.9 | 2.1-4.5 | 7.5-15 | 4.2-8.8 |

| Chemical Resistance | Excellent | Excellent | Superior | Poor | Moderate |

| Impact Strength (ft-lb/in) | 15-28 | 18-32 | 22-38 | 25-45 | 8-15 |

| Service Life | 25+ years | 25+ years | 30+ years | 5-15 years | 10-20 years |

| Maintenance Cost | Very Low | Very Low | Negligible | High | Moderate |

Advanced Performance Visualizations

Industrial Applications and Solutions

The versatility of our Holiday Special Offers GRP FRP Gratings Fiberglass Grates enables deployment across multiple sectors with demonstrated performance advantages:

Chemical Processing Plants: Where corrosion resistance is non-negotiable, our gratings withstand the harshest chemical environments. Unlike metallic alternatives that deteriorate rapidly when exposed to chlorides, acids, and alkaline solutions, our composite gratings maintain structural integrity while eliminating maintenance downtime. Recently, a major petrochemical facility in Guangdong reported 65% lower annual maintenance costs after switching to our solution.

Water Treatment Facilities: Our non-conductive properties make GRP FRP gratings ideally suited for electrolysis zones and areas with high humidity. Additionally, their non-porous surfaces resist biofilm accumulation that leads to sanitation issues in processing water systems. A notable installation in Singapore's NEWater facility has operated flawlessly for over 14 years without degradation despite constant exposure to wastewater byproducts.

- International Journal of Industrial Engineering (2023)

Marine and Offshore Applications: Our specialized resin formulations provide saltwater resistance that dramatically outperforms alternatives. This capability, combined with exceptional strength-to-weight ratios, delivers optimal solutions for offshore platforms, ship decks, and marine walkways. The US Coast Guard-approved anti-slip surfaces ensure worker safety even under extremely wet conditions.

Food & Beverage Processing: Regulatory-compliant formulations meet FDA and EU food contact standards. The smooth, non-absorbent surfaces prevent bacterial growth and allow thorough sanitation that meets stringent hygiene requirements. Major facilities report 40% faster sanitation cycles compared to stainless steel alternatives.

Professional Technical FAQ

Why Choose Zhaojia Composites

As a vertically integrated manufacturer with ISO 9001, ISO 14001, and OHSAS 18001 certifications, Zhaojia Composites Co., Ltd controls every aspect of the production process - from polymer formulation to final quality validation. This comprehensive approach ensures unparalleled quality consistency that distinguishes our Holiday Special Offers GRP FRP Gratings Fiberglass Grates from competitors.

Our commitment to technological advancement has yielded 7 patented innovations in composite manufacturing, resulting in products with superior mechanical properties and extended service life. Clients benefit from the ZJ Performance Advantage™ - delivering lifecycle cost reductions of 30-60% compared to traditional materials through lower installation costs, zero maintenance requirements, and elimination of replacement cycles.

Industry References and Technical Resources

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025