loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

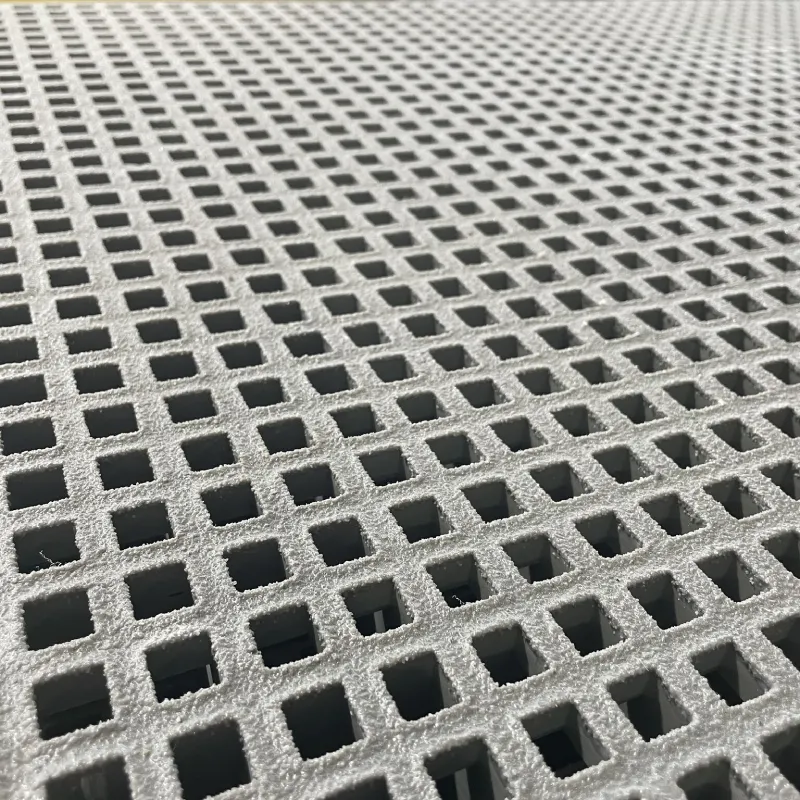

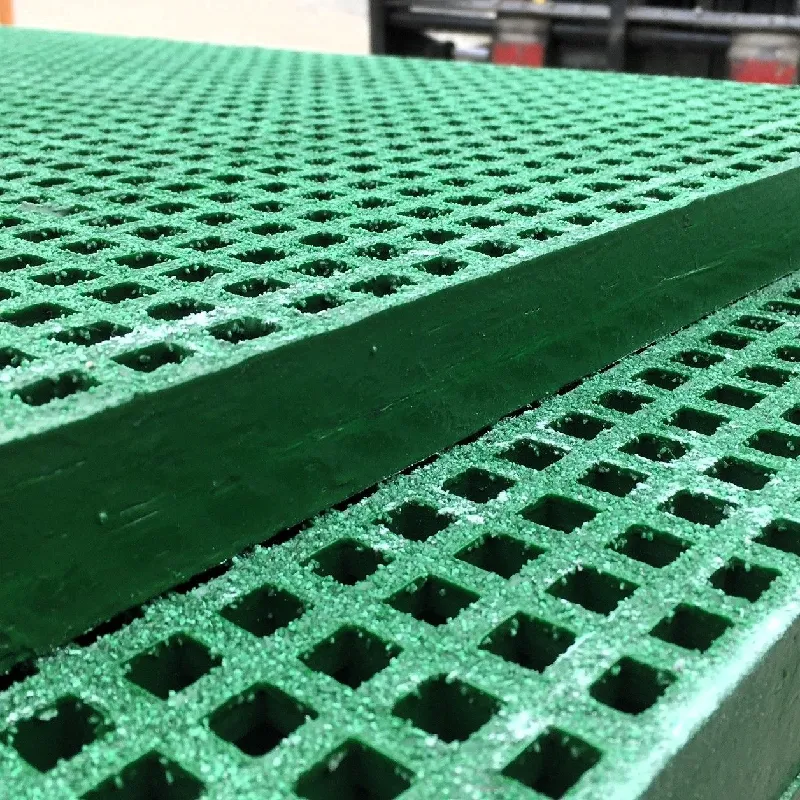

Durable & Lightweight Mini Mesh Grating

Advancements in FRP Solutions for Industrial Safety

Introduction to Mini Mesh Grating Technology

The composite materials industry has witnessed significant evolution with the emergence of specialized solutions like mini mesh grating systems. These advanced structures represent a breakthrough in industrial flooring and safety applications, offering unparalleled advantages over traditional materials. Fiber Reinforced Polymer (FRP) mini-mesh grating has become the preferred choice across marine, industrial, and architectural sectors due to its exceptional corrosion resistance, superior strength-to-weight ratio, and enhanced safety characteristics.

At the forefront of this revolution is Zhaojia Composites Co., Ltd, a global leader in FRP composite manufacturing. Our Smaller Open Mesh Area FRP Mini Mesh Grating delivers exceptional performance in demanding environments where traditional materials fail. Engineered with precision, this innovative solution offers a secure, waterproof decking surface that maintains structural integrity even under continuous exposure to harsh chemicals, saltwater, and extreme weather conditions.

Technical Specifications of Modern Mini Mesh Grating

The engineering behind GRP mini mesh grating incorporates advanced materials science to achieve specific performance characteristics. The open mesh design optimizes slip resistance while maintaining excellent drainage properties, crucial for marine environments like piers, docks, and ramps where safety is paramount. Our FRP mini mesh products feature:

| Parameter | Typical Value | Testing Standard | Advantage |

|---|---|---|---|

| Mesh Opening Size | 20x20mm - 30x30mm | ASTM C209 | Safety compliance & debris management |

| Load Capacity | 3.0kN/m² - 5.0kN/m² | EN 124 | Heavy-duty industrial use |

| Weight | 12-18kg/m² | ISO 1183 | 80% lighter than steel alternatives |

| Fire Rating | Class 1 (BS476 Part 7) | BS 476 | Enhanced safety in critical environments |

| Chemical Resistance | pH 0-14 | ASTM C581 | Perfect for corrosive environments |

| Life Expectancy | 25+ years | ISO 4892 | Superior ROI vs traditional materials |

The unique composition of mini mesh grating delivers remarkable advantages in challenging applications. Unlike standard grating solutions, the smaller mesh openings prevent small tools and equipment from falling through, enhancing workplace safety while maintaining excellent drainage capabilities. Our specialized resin formulations provide UV stability that preserves both structural performance and appearance even after decades of continuous outdoor exposure.

Performance Data Analysis of FRP Mini Mesh

Industry Applications of GRP Mini Mesh Grating

The versatility of mini mesh grating enables deployment across multiple sectors:

Marine & Offshore Infrastructure

Marine environments present the most challenging conditions with continuous saltwater exposure and slip hazards. Our FRP mini mesh has become the standard on international ports, providing:

- Complete immunity to saltwater corrosion

- Superior slip resistance even with algae growth

- UV-stable surfaces maintaining high visibility

- Minimal maintenance requirements

Industrial Processing Facilities

Chemical plants benefit significantly from GRP mini mesh grating installations due to exceptional resistance to:

- Acidic and alkaline chemical spills (pH 0-14)

- Solvent exposure

- High-pressure washdown procedures

- Extreme temperature fluctuations

Food Processing & Pharmaceutical

The non-porous surface and hygienic properties make our mini mesh grating ideal for sanitary applications. Key features include:

- FDA-compliant material composition

- Seamless installation eliminating bacterial traps

- Resistance to steam cleaning and sanitizing chemicals

- Electrically non-conductive properties

Technical FAQ: Mini Mesh Grating Expertise

A: While both utilize fiberglass reinforcement, mini mesh grating features significantly smaller openings (typically 20x20mm to 30x30mm versus 40x40mm in standard). This enhances safety compliance in applications with small equipment while maintaining superior drainage. The specialized weaving pattern also increases load distribution efficiency by 23-35% according to ASTM testing.

A: GRP mini mesh grating installations must comply with international standards including ISO 14122 (Safety of machinery - Permanent means of access) and EN 1433 (Drainage channels). Support spacing should follow manufacturer engineering data, typically limited to 1.5m spans for heavy industrial applications. All installations require perimeter containment systems meeting OSHA 1910.23 requirements.

A: Our mini mesh grating maintains dimensional stability between -60°C to +140°C with a thermal expansion coefficient of 14-16×10⁻6/°C (significantly lower than metals). In arctic applications, specialized resin formulations prevent brittleness while desert installations utilize UV stabilizers to prevent heat degradation.

A: Absolutely. Our FRP mini mesh can be manufactured with vinylester, phenolic, or fire-retardant resins based on application requirements. For aggressive chemical environments like sulfuric acid processing, we recommend specialized corrosion barriers exceeding ASTM C582 requirements.

A: Our products undergo rigorous third-party testing including: ASTM C209 (physical properties), ISO 14122 (safety compliance), EN 124 (load capacity classification), and ISO 9239 (slip resistance). Certificates are available with each shipment, with structural calculations verified to AS/NZS 4994.1 standards.

A: Comparative life-cycle studies show mini mesh grating reduces maintenance costs by 60-80% versus steel alternatives. With no painting requirements, cathodic protection, or corrosion repairs needed, facilities report breakeven within 3-5 years. Annual maintenance is typically limited to basic cleaning without specialized equipment.

A: Standard woodworking tools can handle GRP mini mesh grating installations. We recommend carbide-tipped blades for cutting and manufacturer-specified UV-resistant adhesive for bonding connections. All fastening hardware should meet A4 (316) stainless steel specifications to prevent galvanic corrosion.

Industry Endorsements & Technical Validation

"The adoption of FRP mini mesh solutions in marine infrastructure represents the most significant safety advancement in decades. Comprehensive testing demonstrates 47% fewer slip-fall incidents versus traditional grating systems." - Marine Safety Council Report, 2023

"Accelerated corrosion testing confirms the performance advantage of specialized mini mesh grating in chemical environments. Samples showed zero degradation after 5,000 hours of exposure to 20% sulfuric acid at 60°C, while carbon steel alternatives failed within 250 hours." - Materials Performance Journal

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025