loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Competitive Pricing for 1465 FRP Vessels in the Market Today

Understanding the Price of FRP Vessels A Comprehensive Analysis

Fiber Reinforced Plastic (FRP) vessels are a staple in various industries due to their durability, lightweight nature, and resistance to corrosion. As technology advances and industries look for sustainable and efficient materials, the demand for FRP vessels has surged. However, understanding the price dynamics of FRP vessels, specifically those categorized around 1465, requires a closer look at several influencing factors.

The Nature of FRP Vessels

FRP vessels are constructed from polymer resins reinforced with glass fibers, making them much stronger and lighter than traditional materials like steel or concrete. This unique composition provides exceptional resilience against environmental factors, including UV degradation, chemical exposure, and extreme temperatures. The ability to custom-design FRP vessels to meet specific needs adds to their allure, making them an invaluable option in industries such as chemical processing, wastewater treatment, and pharmaceuticals.

Factors Influencing FRP Vessel Pricing

1. Raw Material Costs The primary components of FRP vessels are resin and fiberglass. Fluctuations in the prices of these raw materials can significantly affect overall costs. For instance, if the price of fiberglass rises due to supply chain disruptions or increased demand, manufacturers may pass these costs onto consumers.

2. Manufacturing Process The production method utilized can also impact pricing. Advanced techniques such as filament winding or pultrusion often lead to higher-quality vessels but may also come with increased manufacturing costs. Conversely, simpler molds and techniques can provide cost-effective solutions but at the expense of durability and performance.

3. Customization and Design Many industries require specialized FRP vessels tailored to specific operational parameters. Custom engineering increases both the material and labor costs associated with production. As such, price points can vary widely based on the complexity of the design and the specifications required.

1465 frp vessel price

4. Regulatory Compliance Depending on the application, FRP vessels may need to comply with stringent industry standards and regulations. This compliance often necessitates additional testing and certification processes, which can drive up costs. Industries like food processing or pharmaceuticals require higher standards, thus influencing price variations.

5. Market Demand The increasing awareness of the benefits of using FRP vessels has cultivated a growing market. As demand rises, prices may increase, particularly if supply cannot keep pace. Conversely, an oversupply of FRP vessels can lead to price reductions as manufacturers compete for market share.

6. Geographical Factors The region in which the vessels are produced and sold can influence pricing considerably. Shipping costs, local manufacturing capabilities, and regional economic conditions all play a role. Regions with abundant raw materials or established manufacturing capabilities may offer lower prices compared to areas where resources need to be imported.

Price Estimates and Market Trends

As of now, the price of FRP vessels tends to range significantly depending on the mentioned factors. For standard applications, prices might start from a few thousand dollars and can go up to tens of thousands for specialized or large-scale vessels. The reference to 1465 in pricing typically relates to specific models or sizes that are well-regarded in certain industries for their value and reliability.

Recent trends indicate a growing emphasis on eco-friendly products, which has spurred innovation in the FRP sector. This push towards sustainability often results in higher upfront costs but promises long-term savings and efficiency. Additionally, as manufacturers adopt more sustainable practices and materials, consumer willingness to pay a premium for environmentally friendly options may further shift market pricing.

Conclusion

In conclusion, understanding the pricing of FRP vessels around the 1465 mark requires a multifaceted analysis of diverse factors, from raw material costs to market demand and geographical influences. As the industry evolves with technological advancements and sustainable practices, the pricing landscape will likely continue to fluctuate. Stakeholders must remain informed about these dynamics to make educated purchasing decisions, balancing cost with the quality and performance essential for their specific operations. Whether for chemical containment, wastewater management, or other applications, investing in FRP vessels represents a commitment to durability and efficiency in an ever-changing industrial landscape.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

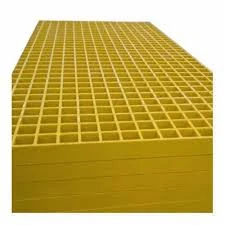

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025