loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Top FRP Rod Manufacturers for Quality Composite Solutions in the Industry

The Role of FRP Rod Manufacturers in Modern Industry

Fiberglass Reinforced Plastic (FRP) rods have transformed various industries with their unique properties and applications. As more sectors recognize the advantages of using FRP materials, the demand for FRP rod manufacturers continues to grow. This article explores the significance of FRP rods, the manufacturing process, and the impact of these manufacturers on different industries.

Understanding FRP Rods

FRP rods are composite materials made from a polymer matrix reinforced with fiberglass. This combination results in products that are lightweight, strong, and resistant to corrosion and environmental degradation. The versatility of FRP rods makes them ideal for numerous applications, including construction, electrical utilities, and marine environments. The non-conductive properties of FRP also make it suitable for use in electrical and telecommunications setups, where traditional metal rods would pose safety risks.

The Manufacturing Process

The manufacturing process of FRP rods involves several stages, ensuring that the final product meets stringent quality and performance standards. The raw materials, primarily fiberglass and resin, are first selected based on the desired properties of the end product. The glass fibers are then woven into mats or aligned in specific orientations to improve strength and durability.

Next, a resin is applied to the fiberglass to create a composite material. This mixture is then molded into the shape of the desired rod and cured, often using heat or ultraviolet light to ensure the resin hardens properly. Advanced FRP rod manufacturers employ state-of-the-art technology, such as filament winding and pultrusion, to enhance precision and efficiency in production. These methods allow for consistent quality and the ability to produce rods of varying lengths and diameters.

The Impact of FRP Rod Manufacturers

frp rod manufacturers

The role of FRP rod manufacturers is crucial in scaling the usage of these materials across various sectors. They not only supply high-quality FRP rods but also contribute to innovative applications and research. As industries look for sustainable and cost-effective solutions, manufacturers are continuously evolving their offerings, expanding product lines, and exploring new technologies to improve performance.

In construction, for instance, FRP rods are increasingly used as reinforcement in concrete structures. Their lightweight nature reduces labor costs and simplifies transportation and installation. Moreover, their corrosion resistance ensures a longer lifespan for structures, reducing maintenance costs over time.

In the energy sector, FRP rods are integral to reinforcing electrical poles and towers, especially in coastal and high-humidity areas where metal components are prone to rust. The durability of FRP materials allows for greater resilience against adverse weather conditions, thereby enhancing the reliability of power supply systems.

Sustainability and Future Prospects

Moreover, the manufacturing of FRP rods aligns with sustainable practices. The lightweight nature of these rods contributes to reduced energy consumption during transportation and installation. As industries increasingly prioritize eco-friendly materials, FRP manufacturers are positioned to play a pivotal role in driving this change.

Looking ahead, the future of FRP rod manufacturing appears promising. Ongoing research is likely to lead to the development of even more advanced composite materials, catering to specialized applications across different fields. Manufacturers who embrace innovation and adaptability will lead the way in this evolving market.

Conclusion

In conclusion, FRP rod manufacturers are essential players in various industries, providing products that combine strength, durability, and sustainability. Their impact is felt across the construction, energy, and telecommunications sectors, helping to meet the evolving needs of modern infrastructure. As demand continues to grow, these manufacturers will undoubtedly contribute to the development of new applications and materials, shaping the future of industrial practices.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

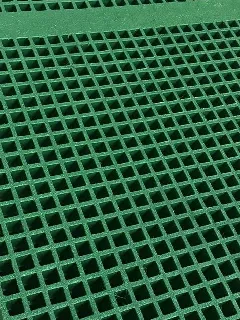

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025