tagħbija...

- Nru 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, iċ-Ċina

- admin@zjcomposites.com

- +86 15097380338

- Merħba żur il-websajt tagħna!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Ingliż

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

A Durable Solution for Every Industry

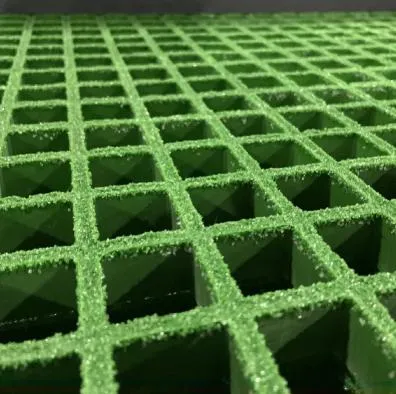

FRP grating offers exceptional durability and versatility for various industrial and commercial applications. With its growing popularity, this advanced material continues to provide unmatched performance across multiple sectors. In this article, we’ll delve into the benefits of FRP grating, FRP grating panels, and FRP micro mesh grating, exploring why they are becoming the go-to solutions for industries that demand high-strength, corrosion-resistant materials.

FRP Grating: A Reliable Solution for Tough Environments

FRP grating (Fiberglass Reinforced Plastic) is known for its exceptional resistance to corrosion, making it the ideal material for industries where environmental conditions are harsh. Whether it's exposure to chemicals, saltwater, or extreme temperatures, FRP grating stands up to these challenges better than traditional metal options. The lightweight nature of FRP grating also makes it easy to handle and install, reducing labor costs and improving overall project efficiency.

FRP Grating Panels: Versatile and Strong

FRP grating panels are available in a wide variety of designs and sizes, making them adaptable to a range of applications. From platforms and walkways to drainage systems and stair treads, FRP grating panels are versatile enough to meet the specific requirements of your project. These panels offer superior strength, ensuring long-term performance even in the most demanding environments. Additionally, FRP grating panels are non-conductive, reducing the risk of electrical hazards in industrial settings.

FRP Micro Mesh Grating: Precision and Performance

For applications that require a finer mesh, FRP micro mesh grating provides the perfect solution. This type of grating features smaller openings than standard FRP grating, allowing for more precise applications. FRP micro mesh grating is ideal for environments where small debris or particles need to be filtered out or where the surface needs to provide enhanced support for smaller loads. Its durability and strength make it a popular choice for industries like pharmaceuticals, food processing, and electronics.

Why Choose FRP Grating for Your Industrial Needs?

When it comes to choosing materials for industrial applications, the decision often comes down to durability, strength, and resistance to environmental factors. FRP grating excels in all these areas, offering long-lasting performance in environments that would degrade other materials. Additionally, FRP grating is easy to maintain, reducing downtime and replacement costs. Whether you're constructing walkways, platforms, or even chemical-resistant flooring, FRP grating ensures that your structure remains safe and reliable for years to come.

The Future of FRP Grating Panels and FRP Micro Mesh Grating

As industries continue to seek out more durable, lightweight, and environmentally-friendly materials, the demand for FRP grating panels and FRP micro mesh grating is expected to grow. Innovations in production processes will only improve the performance and affordability of these products, making them even more accessible for a wide range of applications. Whether you're in construction, manufacturing, or another heavy-duty sector, FRP grating is an investment in quality and longevity.

In conclusion, the use of FRP grating, FRP grating panels, and FRP micro mesh grating offers significant advantages over traditional materials. With their superior strength, corrosion resistance, and versatility, these products are setting new standards in industries worldwide. Choose FRP grating for your next project, and experience the durability and performance that these cutting-edge materials provide.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingAħbarijietNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersAħbarijietNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessAħbarijietNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesAħbarijietNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectAħbarijietNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesAħbarijietNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingAħbarijietNov.11,2025