memuatkan...

- 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Selamat datang untuk melawat laman web kami!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Inggeris

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Why FRP Grating Panels are the Best Choice for Your Industrial Needs

In industrial settings, safety, durability, and cost-effectiveness are essential factors when choosing materials. One of the top materials that have been gaining traction in industries worldwide is FRP (Fiber-Reinforced Plastic) grating. It is known for its excellent strength, non-corrosive nature, and ability to withstand harsh environments. Whether you’re looking for a solution for walkways, platforms, or drainage, FRP grating panels are an ideal choice. In this article, we will discuss the importance of FRP grating panels, how to find the best FRP grating manufacturer, and the FRP grating cost per square foot to help you make an informed purchasing decision.

What Are FRP Grating Panels?

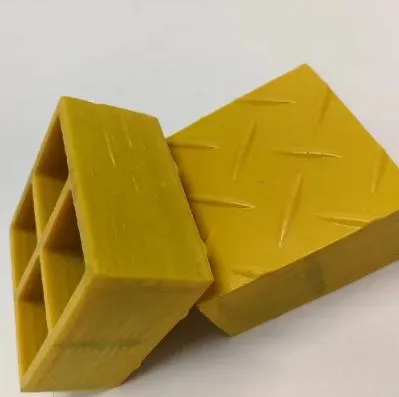

FRP grating panels are industrial-grade flooring systems made from a combination of fiberglass and resin. The result is a material that offers remarkable strength while being lightweight, durable, and resistant to corrosion. These panels are used in various industries, including chemical, food processing, marine, and wastewater treatment, where they help create safe and functional surfaces.

The key benefits of FRP grating panels are their ability to resist harsh chemicals, moisture, and extreme temperatures. Unlike traditional steel or aluminum gratings, FRP grating does not rust or degrade over time, making it an ideal solution for areas exposed to corrosive elements. These panels are also slip-resistant, providing added safety in environments where workers may be exposed to liquids or hazardous substances.

Moreover, FRP grating panels are available in a variety of sizes, colors, and designs, allowing them to be tailored to specific applications. This versatility makes them a preferred choice for a wide range of industries that demand high performance from their materials.

Choosing the Right FRP Grating Manufacturer for Your Needs

Selecting the right FRP grating manufacturer is crucial for ensuring you get high-quality panels that meet industry standards. A reliable FRP grating manufacturer should offer a variety of products, excellent customer service, and customizable solutions that meet your specific needs. It's important to work with a manufacturer who understands your requirements and provides technical support throughout the installation process.

When choosing an FRP grating manufacturer, look for companies that use high-quality resins and fiberglass materials. The durability and lifespan of your grating panels depend significantly on the materials used in their construction. Leading manufacturers typically offer options with superior resistance to UV degradation, impact, and fire. They may also provide different types of grating, such as molded or pultruded, to accommodate various applications.

Another critical factor when selecting an FRP grating manufacturer is the ability to deliver on time. In industries where downtime can be costly, a manufacturer that can meet deadlines and ensure fast delivery of high-quality products is essential. Moreover, ensure that the manufacturer you choose offers warranties and after-sales support, as this guarantees the long-term performance of your panels.

Understanding FRP Grating Cost Per Square Foot

The FRP grating cost per square foot is an important consideration when planning your project. FRP grating cost per square foot can vary based on several factors, including the type of resin used, the design, the size of the panels, and the quantity purchased. Typically, molded FRP grating is less expensive than pultruded FRP grating, but it may offer slightly lower load-bearing capacity.

On average, the FRP grating cost per square foot can range from $10 to $50 or more. Keep in mind that while FRP grating may have a higher initial cost compared to other materials like steel or aluminum, it provides long-term savings due to its durability and minimal maintenance requirements. The lifespan of FRP grating is significantly longer than that of traditional metal grating, making it a more cost-effective choice over time.

It's essential to get a quote from the FRP grating manufacturer for the specific panels you need. Consider factors such as the amount of grating required for your project, any customization options (such as anti-slip surfaces or specific color choices), and additional shipping costs. Investing in high-quality FRP grating panels may have a higher upfront cost, but the longevity and performance of the material can deliver significant savings over the life of your project.

Benefits of Using FRP Grating Panels in Industrial Applications

FRP grating panels offer a range of advantages over traditional materials like steel or aluminum, making them the preferred choice for industrial applications. These benefits include:

Corrosion Resistance: One of the most significant advantages of FRP grating panels is their resistance to corrosion. Unlike metal grating, which can rust and degrade over time, FRP panels will remain intact in corrosive environments. This feature makes them ideal for industries such as chemical processing, wastewater treatment, and marine applications.

Lightweight and Easy to Install: FRP grating panels are much lighter than steel or aluminum grating, which makes them easier to transport and install. This reduces installation time and labor costs, making them a more cost-effective choice in the long run.

Slip Resistance: FRP grating panels are designed with a slip-resistant surface, reducing the risk of accidents in areas that may be exposed to water, oils, or chemicals. This feature is particularly important in work environments where safety is a top priority.

Customization: Many FRP grating manufacturers offer custom solutions to meet the unique needs of their clients. From different sizes and colors to specialized configurations, you can customize your grating to fit the exact requirements of your project.

Long Lifespan: The durability and strength of FRP grating panels ensure they provide a long lifespan, even in the most demanding conditions. This minimizes the need for replacement and reduces maintenance costs over time.

Installation and Maintenance of FRP Grating Panels

Installing FRP grating panels is relatively straightforward, particularly because of their lightweight nature and ease of handling. However, proper installation techniques should be followed to ensure that the panels are secure and functional for years to come.

When installing FRP grating panels, it is important to use the correct fasteners and supports based on the load-bearing requirements of the application. Depending on the size and type of grating, additional supports or reinforcements may be necessary to ensure stability and prevent shifting.

Maintenance of FRP grating panels is minimal compared to traditional metal grating. The material is resistant to wear and tear, so you won’t need to worry about rust or corrosion. However, periodic cleaning is recommended to maintain their appearance and functionality. Simply wash the grating with water and mild soap to remove debris and dirt.

For highly corrosive environments, periodic inspections should be conducted to ensure the integrity of the panels. If damage is detected, it’s typically easy to replace individual panels, further extending the lifespan of the entire system.

FRP Grating Panels FAQs

How long do FRP grating panels last?

FRP grating panels can last up to 30 years or more, depending on the environment and the type of resin used. The material is highly durable and resistant to corrosion, making it a long-lasting solution for industrial applications.

Are FRP grating panels easy to install?

Yes, FRP grating panels are lightweight and easy to handle, making installation straightforward. However, it is essential to follow proper installation guidelines and use the appropriate fasteners to ensure secure placement.

What factors affect the FRP grating cost per square foot?

Several factors can affect the cost, including the type of resin used, the design of the grating, and the manufacturer. Customization options such as color, anti-slip surfaces, and panel size can also influence the price.

Can FRP grating panels be used outdoors?

Yes, FRP grating panels are designed to withstand outdoor conditions, including exposure to UV rays, moisture, and temperature fluctuations. They are a popular choice for outdoor walkways, platforms, and drainage systems.

How do I choose the right FRP grating manufacturer?

When choosing a manufacturer, consider factors such as product quality, range of options, customer support, and delivery times. It’s essential to work with a manufacturer that offers durable, high-performance grating and can meet your specific project needs.

In conclusion, FRP grating panels are an excellent choice for industries that require durable, safe, and corrosion-resistant flooring solutions. By understanding the FRP grating manufacturer options available and considering the FRP grating cost per square foot, you can make an informed decision that will provide long-term benefits for your project.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingBeritaNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersBeritaNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessBeritaNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesBeritaNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectBeritaNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesBeritaNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingBeritaNov.11,2025