ກຳລັງໂຫຼດ...

- ເລກ 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, ຈີນ

- admin@zjcomposites.com

- +86 15097380338

- ຍິນດີຕ້ອນຮັບເຂົ້າສູ່ເວັບໄຊທ໌ຂອງພວກເຮົາ!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- ພາສາອັງກິດ

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

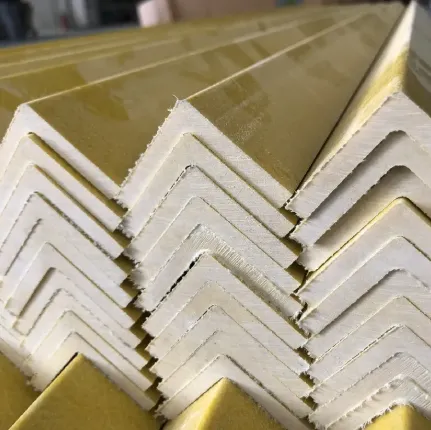

GRP Structures: The Future of Lightweight, High-Performance Engineering

Lightweight, durable, and built to outperform traditional materials in even the harshest environments—grp structures are rapidly becoming the preferred choice across multiple industries. Whether used in construction, offshore platforms, water treatment plants, or heavy-duty access systems, these innovative solutions deliver exceptional strength, unmatched corrosion resistance, and eco-friendly benefits.

The Unbeatable Weather Resistance and Eco-Performance of GRP Structures

One of the most compelling reasons companies turn to grp structures is their outstanding resilience against the elements. Unlike metal or wood, which degrade over time when exposed to moisture, UV rays, or extreme temperatures, grp structures remain unaffected by harsh weather. The polymer matrix and reinforced glass fibers provide natural resistance to salt spray, acid rain, and intense sunlight, making them ideal for coastal or marine environments.

But performance isn’t the only advantage—grp structures offer a significantly reduced carbon footprint. Their manufacturing requires less energy than steel or concrete production, and they are often fully recyclable. In applications like wastewater treatment facilities or power substations, the long lifespan and minimal maintenance needs of grp structures reduce environmental impact and operational costs at once.

Earthquake-Ready: Seismic Stability in GRP Structural Applications

Seismic resilience is another hidden strength of the glass reinforced plastic structure. Unlike traditional materials that can fracture or collapse under seismic strain, GRP’s inherent flexibility and lightweight design allow it to absorb and distribute earthquake forces more effectively. This is especially critical in infrastructure projects located in seismic zones.

Engineering tests demonstrate that grp structures can handle lateral forces without splintering or deforming, thanks to their balanced tensile strength and elastic properties. When paired with anchoring systems designed for dynamic loads, grp structures serve as a reliable and safe solution for bridges, platforms, cable trays, and more in areas prone to tremors or aftershocks.

Why GRP Structures Are Gaining Ground Globally

The popularity of grp structures is more than just a passing trend—it’s a direct result of their proven advantages in cost, installation efficiency, and longevity. Traditional metal structures often demand heavy machinery and large crews for installation. In contrast, grp structures are modular and lightweight, which means they can be transported more easily and installed with minimal manpower.

Their resistance to rust, chemical corrosion, and biological degradation significantly reduces lifecycle costs. Industries like chemical processing, transportation, and marine construction have fully embraced grp structures due to their low maintenance demands and the safety they provide in hazardous environments.

Moreover, the aesthetic flexibility of GRP materials enables custom colors and finishes, making them suitable for high-visibility public installations without sacrificing performance.

Heavy Duty Fiberglass Grating: The Workhorse of Composite Platforms

When load-bearing capacity meets corrosion resistance, the result is heavy duty fiberglass grating—a specialized form of GRP flooring designed to handle extreme pressures while offering safety and drainage. Perfect for chemical plants, oil rigs, food production zones, and pedestrian platforms, heavy duty fiberglass grating resists chemicals, impacts, and slippage.

Unlike metal grates that rust or wood planks that rot, heavy duty fiberglass grating is built to last for decades under constant exposure to water, chemicals, and UV rays. Its high load ratings and anti-slip surfaces make it a favorite for walkways, stair treads, trench covers, and loading platforms. The open mesh design also allows for superior ventilation and fluid drainage—critical in environments where cleanliness and safety are paramount.

Installers appreciate the lightweight nature of heavy duty fiberglass grating, which reduces transport and labor costs, while plant managers value its low maintenance profile and compliance with OSHA safety standards.

GRP Structures FAQs

What makes grp structures environmentally friendly?

GRP structures require less energy to manufacture compared to traditional materials and offer longer lifespans with fewer replacements, reducing overall environmental impact. They’re also often recyclable and don’t corrode or leach harmful substances.

How do grp structures perform during earthquakes?

Thanks to their lightweight yet flexible composition, grp structures absorb seismic energy better than rigid materials. Their elasticity helps distribute stress evenly, minimizing the risk of structural failure in earthquake-prone zones.

What applications are best suited for heavy duty fiberglass grating?

Heavy duty fiberglass grating is ideal for chemical plants, offshore platforms, wastewater facilities, and anywhere that combines corrosive environments with high traffic or heavy loads. It provides durable, safe flooring that won’t rust or decay.

Why is the glass reinforced plastic structure replacing steel in some projects?

A glass reinforced plastic structure is non-corrosive, lightweight, easier to install, and more resistant to chemicals and UV radiation than steel. It significantly lowers installation and maintenance costs while offering long-term durability.

Are grp structures customizable for unique architectural needs?

Yes, grp structures can be manufactured in custom colors, shapes, and finishes. Whether you need modular platforms, decorative facades, or curved elements, GRP’s adaptability allows for full customization without compromising structural integrity.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh Gratingຂ່າວNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global Wholesalersຂ່າວNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale Successຂ່າວNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial Spacesຂ່າວNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every Projectຂ່າວNov.14,2025

-

FRP Pressure Vessels by ZJ Compositesຂ່າວNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp Gratingຂ່າວNov.11,2025