loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

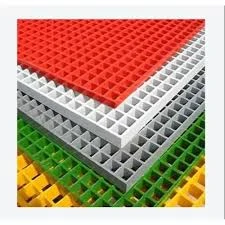

glass reinforced plastic structure

Understanding Glass Reinforced Plastic Structures A Comprehensive Overview

Glass Reinforced Plastic (GRP), often known as fiberglass, is a composite material made of a polymer matrix reinforced with glass fibers. This combination results in a lightweight yet durable material used in various applications across multiple industries, including automotive, marine, construction, and aerospace. The characteristics that make GRP an attractive option for these applications stem from its unique structural properties and versatility.

What is Glass Reinforced Plastic?

At its core, GRP consists of two main components a thermosetting resin and glass fibers. The resin provides the matrix that binds the fibers together, while the glass fibers enhance strength and stiffness. The ratio of glass to resin can be adjusted to tailor the material's properties for specific applications, making GRP highly customizable. Common resins used in the production of GRP include epoxy, polyester, and vinylester, each contributing different mechanical and thermal properties.

Properties of GRP

The inherent advantages of GRP arise from its composite nature. First and foremost, GRP boasts exceptional strength-to-weight ratios. This property is particularly beneficial in applications where weight reduction is crucial, such as in the aerospace industry, where minimizing mass can significantly enhance fuel efficiency.

Moreover, GRP exhibits excellent resistance to corrosion and environmental degradation, making it ideal for use in harsh environments, such as in chemical processing facilities or marine applications. Unlike metals, GRP does not corrode over time, thereby extending its service life and reducing maintenance costs.

Furthermore, GRP has good thermal insulation properties, making it suitable for applications where temperature fluctuations can be problematic

. It is also a non-conductor of electricity, adding another layer of safety in electrical applications.Applications of GRP Structures

glass reinforced plastic structure

The versatility of GRP has led to its widespread adoption across various sectors. In the maritime industry, GRP is commonly used for boat hulls and other components due to its lightweight nature and resistance to water damage. In the automotive field, it is utilized in body panels, interiors, and structural components, contributing to improved fuel efficiency through weight reductions.

In construction, GRP has gained popularity for fabrication of architectural elements, such as cladding, roofing, and structural beams. Its design flexibility allows architects to create complex shapes and aesthetics that would be challenging to achieve with traditional materials. Additionally, GRP is frequently used in building infrastructure, like bridges and walkways, due to its durability and low maintenance requirements.

In the aerospace sector, GRP is employed in various components, including fuselage sections, wings, and other critical structures. The consistent performance and reliability of GRP contribute to safer and more efficient aircraft designs.

Environmental Considerations

Although GRP offers numerous advantages, its manufacturing and disposal raise some environmental concerns. The production of fiberglass involves the use of resins and chemicals, which can be harmful if not managed properly. However, advancements in technology are leading to more sustainable practices, such as developing bio-based resins and recycling methods for fiberglass.

Moreover, as awareness of sustainability grows, researchers are actively exploring biodegradable alternatives and enhancements to improve the recyclability of GRP. This ongoing innovation aims to minimize the environmental impact of GRP production and disposal, making it a more sustainable option for the future.

Conclusion

Glass Reinforced Plastic structures represent a remarkable fusion of materials science and engineering, providing a combination of strength, durability, and versatility that is hard to match. From automotive components to marine applications and architectural designs, GRP continues to evolve, adapting to meet the ever-changing demands of diverse industries. As technology advances and sustainability becomes increasingly paramount, the future of GRP looks promising, with potential innovations that could further enhance its performance and environmental footprint. Understanding these structures and their capabilities is crucial for industries looking to leverage the benefits of this advanced composite material.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025