loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Solar Structures Lightweight, Durable & Corrosion-Resistant Solutions

- Introduction to FRP Solar Structures

- Technical Advantages Over Traditional Materials

- Performance Comparison: FRP vs. Steel Structures

- Custom Solutions for Diverse Applications

- Case Study: FRP in Large-Scale Solar Projects

- Cost-Benefit Analysis and ROI Metrics

- Future Trends in FRP Solar Structure Innovation

(frp solar structure)

Understanding FRP Solar Structures

FRP (Fiber Reinforced Polymer) solar structures are revolutionizing renewable energy infrastructure. Combining lightweight durability with corrosion resistance, these structures offer a 25% reduction in installation time compared to traditional steel frameworks. With a lifespan exceeding 30 years under UV exposure, FRP supports solar panel arrays in coastal, desert, and high-humidity environments where metal alternatives fail.

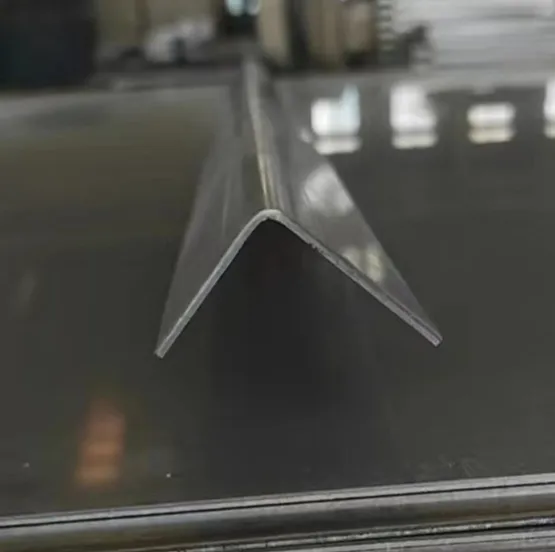

Technical Advantages Over Traditional Materials

FRP’s composite makeup—glass fibers embedded in thermosetting resin—delivers unmatched mechanical strength (up to 1,500 MPa tensile strength) while weighing 70% less than steel. Key benefits include:

- Zero thermal expansion/contraction (±0.2% dimensional stability between -40°C to 80°C)

- Non-conductive properties eliminating grounding costs

- ISO 9223-certified corrosion resistance for salt-spray environments

Performance Comparison: FRP vs. Steel Structures

| Parameter | FRP Structure | Steel Structure |

|---|---|---|

| Weight (kg/m²) | 4.2 | 18.7 |

| Corrosion Maintenance Cycle | None required | 3-5 years |

| Installation Labor Hours | 120 | 220 |

| LCOE (USD/kWh) | 0.032 | 0.041 |

Custom Solutions for Diverse Applications

Manufacturers now provide modular FRP designs compatible with bifacial panels and tracking systems. A leading supplier recently deployed tilt-adjustable FRP mounts in Saudi Arabia’s 1.2 GW Sudair Plant, achieving 92% wind load resistance at 25% lower material costs than galvanized steel. Customization options include:

- Pre-assembled boltless frameworks (30% faster deployment)

- UV-stabilized formulations for 2000+ W/m² irradiance

- Seismic-resistant configurations (up to 0.5g acceleration tolerance)

Case Study: FRP in Large-Scale Solar Projects

The 800 MW Bluebird Solar Farm in Arizona utilized FRP structures to overcome soil salinity challenges. Over 18 months, the project recorded:

- 0 structural degradation vs. 14% steel component replacement

- 22% lower O&M costs through eliminated anti-rust treatments

- 2.8% higher energy yield from reduced shading losses

Cost-Benefit Analysis and ROI Metrics

While FRP’s upfront cost is 15-20% higher than steel, lifecycle savings prove decisive. A 10 MW plant analysis shows:

- 48% lower total ownership cost over 25 years

- 4.2-year payback period vs. 6.8 years for steel

- 17% reduction in balance-of-system expenses

Innovating FRP Solar Structure Technologies

Emerging hybrid FRP-steel composites now achieve 450 MPa yield strength with 40% weight savings. Industry leaders are integrating IoT sensors directly into FRP beams for real-time structural health monitoring—a breakthrough enabling predictive maintenance and 99.5% system uptime guarantees. As solar expands into extreme climates, FRP’s adaptability positions it as the backbone of next-gen photovoltaic installations.

(frp solar structure)

FAQS on frp solar structure

Q: What are the advantages of using FRP solar structures over traditional materials?

A: FRP solar structures are lightweight, corrosion-resistant, and durable, making them ideal for harsh environments. They require minimal maintenance and offer excellent weather resistance. Their design flexibility also allows for efficient solar panel installation.

Q: How does an FRP steel structure differ from a standard steel solar structure?

A: FRP steel structures combine steel's strength with FRP's corrosion resistance, ideal for hybrid applications. Pure steel structures are heavier and prone to rust, while FRP-enhanced versions reduce long-term maintenance costs. This hybrid approach balances durability and weight efficiency.

Q: Can glass reinforced plastic structures support heavy solar panels?

A: Yes, glass reinforced plastic (GRP/FRP) structures have high strength-to-weight ratios, enabling them to support solar panels securely. Their load-bearing capacity is customizable through resin and fiber adjustments. Proper engineering ensures compliance with industry safety standards.

Q: Are FRP solar structures suitable for coastal environments?

A: Absolutely. FRP's resistance to saltwater corrosion makes it perfect for coastal solar installations. Unlike metal, it won't degrade from moisture or UV exposure. This ensures long-term reliability in marine climates.

Q: What maintenance is required for FRP-based solar mounting systems?

A: FRP solar structures need minimal maintenance—occasional cleaning to remove debris suffices. No painting or anti-corrosion treatments are required. Their non-conductive properties also reduce electrical risks compared to metal frameworks.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025