lueden...

- 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Wëllkomm op eiser Websäit ze besichen!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Englesch

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

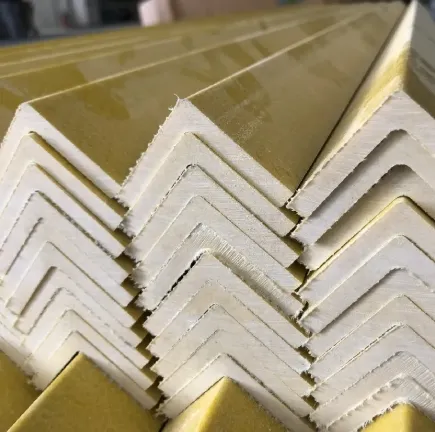

Corrosion-Resistant: The Complete Guide to FRP Square Tubes and Pipes

An FRP square tube is a type of structural component made from fiberglass reinforced plastic (FRP), combining glass fibers with resin to form a durable, lightweight composite. Unlike traditional metal tubes, FRP square tubes provide excellent resistance to corrosion, chemicals, and environmental degradation. This makes them ideal for use in harsh industrial environments such as chemical plants, marine applications, and wastewater treatment facilities.

The manufacturing of FRP square tubes often uses pultrusion, a process that pulls continuous glass fibers through resin and then through a heated die to form rigid, dimensionally stable profiles. This produces tubes with consistent strength and shape that can be customized in terms of thickness, fiber orientation, and resin type to meet specific performance needs.

FRP square tubes are increasingly favored because they reduce structural weight, which lowers transportation and installation costs, while offering electrical insulation and maintenance-free service life.

Advantages and Applications of FRP Square Pipe

The FRP square pipe is functionally similar to the tube but is often used in piping systems where square cross-sections are required. These pipes combine the benefits of fiberglass composites with the practical advantages of square geometry, which is easier to integrate into certain mechanical or architectural designs.

Because of their corrosion resistance, FRP square pipes are widely used in chemical processing plants, cooling towers, underground piping networks, and electrical conduit applications. The pipes resist acid, alkali, and saline environments far better than steel or aluminum alternatives.

Moreover, the non-conductive properties of FRP make these pipes suitable for electrical conduit systems, preventing electrical hazards. The lightweight nature simplifies handling, reduces labor costs, and enables easier installation in confined or elevated spaces.

What Determines the FRP Square Tube Price?

When evaluating the FRP square tube price, several important factors come into play. Tube size and wall thickness directly impact material consumption and thus cost. Larger cross-sections and thicker walls require more resin and fiberglass.

The type of resin used also affects price: polyester resins are typically the most economical, while vinyl ester and epoxy resins offer superior chemical resistance and strength but at a higher cost. The manufacturing process, such as pultrusion or filament winding, also influences pricing due to differences in production speed and labor intensity.

Volume discounts can reduce the per-unit cost when purchasing in bulk. Additionally, custom orders involving special colorants, fire retardants, or UV stabilizers may increase costs.

Although the initial FRP square tube price might be higher than steel, the lower maintenance, extended service life, and resistance to corrosion often make it more cost-effective over the long term.

Maintenance and Longevity of FRP Square Tubes and Pipes

One of the key benefits of FRP materials is their low maintenance requirements. Unlike steel, FRP square tubes and pipes do not rust or corrode, eliminating the need for periodic repainting or chemical treatments.

Cleaning usually requires only water and mild detergents. FRP also withstands exposure to UV rays with appropriate resin formulations or surface coatings, preventing brittleness or color fading.

Regular inspection for physical damage or wear is recommended, especially in load-bearing applications. Minor scratches or surface abrasions typically do not affect structural integrity due to the protective resin matrix.

With proper care, FRP square tubes and pipes can last for 20 to 30 years or more, making them reliable components for long-term construction and infrastructure projects.

FRP SFirwat? Tube Price FAQS

What materials are used in FRP square tubes?

They consist of fiberglass reinforcements embedded in polymer resins, typically polyester, vinyl ester, or epoxy.

Are FRP square pipes suitable for chemical environments?

Yes, especially those made with vinyl ester or epoxy resins offer excellent resistance to acids, alkalis, and solvents.

How does the price of FRP square tubes compare to steel?

FRP tubes usually have a higher upfront cost but save money over time due to corrosion resistance and reduced maintenance.

Can FRP tubes be customized in size and color?

Yes, manufacturers offer customization in dimensions, wall thickness, colors, and surface finishes to suit specific applications.

Is installation of FRP square tubes complicated?

No, they are lightweight and easy to cut, drill, and assemble using standard tools, reducing labor time and costs.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNeiegkeetenNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNeiegkeetenNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNeiegkeetenNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNeiegkeetenNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNeiegkeetenNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNeiegkeetenNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNeiegkeetenNov.11,2025