loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

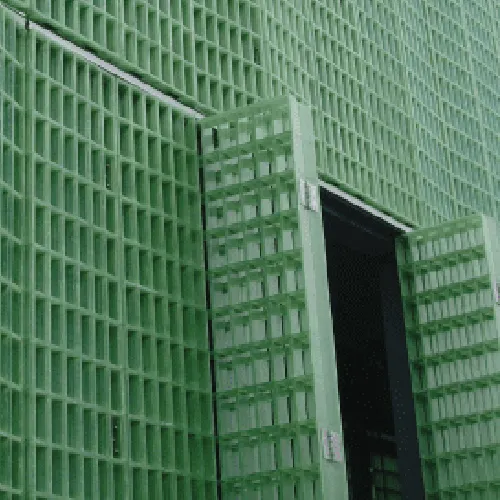

frp grating panels

The unyielding march of technology continually ushers in new materials designed for specific purposes, and one such innovation is the FRP grating panel. Known for their impressive durability, corrosion resistance, and lightweight nature, FRP (Fiberglass Reinforced Plastic) grating panels are gaining significant traction across various industries ranging from construction to shipping.

FRP grating panels are crafted by weaving continuous fiberglass strands with resin, creating a matrix that offers strength akin to steel but with considerably less weight. This unique construction imparts several advantages, the foremost being their outstanding resistance to chemical corrosion. In industries such as chemical manufacturing or wastewater treatment, where exposure to corrosive substances is common, FRP grating panels provide a lasting solution that ensures infrastructure stability and safety.

The expertise behind FRP manufacturing is grounded in detailed knowledge of composite materials and processes. A key facet is the pultrusion technique—a continuous process where resin-impregnated fibers are pulled through heated dies to shape them into desired profiles. This advanced technology not only guarantees uniformity in panel construction but also bolsters their mechanical properties, certifying their capacity to withstand extreme environmental conditions and heavy loads without deformation.

Moreover, the non-conductive nature of FRP grating panels makes them an ideal choice for applications in electrical-sensitive environments. Unlike metal alternatives which pose risks of conduction and spark, these panels offer a safe, reliable option, protecting both equipment and personnel. This safety advantage is further amplified in wet and slippery conditions, where the inherent slip-resistance of FRP surfaces helps prevent accidents, ensuring workplace safety and regulatory compliance.

frp grating panels

Beyond safety and durability, FRP panels also score high on efficiency and sustainability. Their lightweight nature translates into lower transportation and installation costs, as they require minimal heavy lifting equipment—sometimes assembled solely by hand. Additionally, their long lifecycle reduces the need for frequent replacements, thus minimizing environmental footprints over time. When old panels do need replacing, their materials are often recyclable, aligning with modern sustainability standards.

Industry authorities consistently laud FRP grating panels for these attributes, citing numerous case studies where transitions from traditional materials to FRP have resulted in enhanced performance and cost savings. For instance, refineries switching to FRP structures have reported decreased maintenance downtime, while marine environments have seen extended lifespans in decking and walkways exposed to saltwater.

Trust in FRP technology continues to grow as regulatory agencies conduct rigorous testing and certification, ensuring these panels meet relevant safety and performance standards globally. As an example, panels are often subjected to rigorous ASTM and EN testing, validating their claims for load bearing and environmental resistance.

In conclusion, FRP grating panels represent a significant leap forward in material technology, offering a compelling blend of strength, safety, and sustainability. As industries face increasing demands for resilient and efficient materials, embracing FRP technology can provide tangible benefits, securing infrastructure integrity and operational productivity for years to come.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025