loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

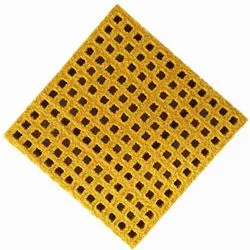

grating frp

In the ever-evolving world of construction materials, fiberglass-reinforced plastic grating (FRP grating) has emerged as a leading choice for engineers and architects focused on innovation and sustainability. FRP grating, known for its versatility and robust nature, is transforming the landscape of industrial applications. These gratings are not only corrosion-resistant but also lightweight, making them ideal for environments that are challenging for traditional materials like steel and wood.

The unique composition of FRP grating gives it an edge in areas prone to harsh weather conditions and chemical exposure. In industries like chemical processing, wastewater treatment, and maritime settings, FRP gratings serve as durable flooring solutions and walkways. The intrinsic properties of fiberglass ensure that the grating does not rust, rot, or warp, drastically reducing maintenance costs and extending the lifespan of these installations. This durability under extreme conditions has earned FRP grating a reputation for providing long-term cost efficiency.

One of the most significant advantages of FRP grating is its exceptional strength-to-weight ratio. Unlike metallic gratings, FRP is far lighter, which simplifies installation and reduces the structural burden on underlying supports. This characteristic is crucial for retrofitting older structures where weight limitations are a concern. Installations become more manageable, time-efficient, and economical, without sacrificing safety standards.

From an engineering perspective, FRP grating offers unparalleled customization. It can be molded into various shapes and sizes, with options for different textures and colors. This adaptability allows it to meet specific project requirements, including slip resistance, load capacity, and aesthetic appeal. The non-conductive nature of FRP also adds a layer of safety in electrical applications, further broadening its applicability across different industries.

grating frp

Sustainability is another pillar supporting the rising popularity of FRP grating. The production process is less resource-intensive compared to traditional materials, and the longevity of FRP reduces the environmental impact over time. As industries worldwide are increasingly focusing on eco-friendlier solutions, using FRP grating aligns with global sustainability goals.

In environments where hygiene and cleanliness are vital, such as food processing and healthcare facilities, FRP grating is a preferred choice. It does not harbor bacteria or moisture, thus meeting stringent sanitation requirements. These features not only assure safety and hygiene but also enhance the trustworthiness of spaces that require high standards of cleanliness.

Experts in the field have noted that as research and development in composite materials progress, the applications and functionalities of FRP grating continue to expand. This positions FRP as a future-proof investment for many industries seeking long-term, reliable, and sustainable material solutions.

As the knowledge surrounding FRP evolves, it increasingly reflects a material that combines experience with technical expertise. Its continued use across demanding environments testifies to its authoritativeness in the field. Consequently, FRP grating represents not only a practical solution but an authoritative material choice that keeps pace with modern challenges and demands.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025