loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

កុម្ភៈ . 18, 2025 10:06

Back to list

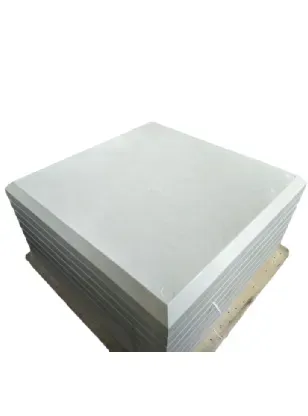

Smaller Open Mesh Area FRP Mini Mesh Grating

Floor steel grating has emerged as an essential component in contemporary architecture and industrial design, owing to its strength, durability, and versatility. This article delves into the aspects that make floor steel grating a superior choice for a wide array of applications, highlighting its experience-driven design, expert craftsmanship, authoritative manufacturing standards, and trustworthy performance in demanding environments.

Trustworthiness is inherent in floor steel grating due to its exceptional resistance to harsh environmental conditions. Galvanized coatings enhance its corrosion resistance, ensuring longevity even in settings exposed to moisture, chemicals, or extreme temperatures. This reliability reduces maintenance costs and extends the lifespan of installations, delivering long-term value to businesses and infrastructure projects. Real-world applications further establish the reliability of floor steel grating. For instance, in industrial platforms or walkways, where safety is a paramount concern, grating systems reduce the risk of slips and falls due to their high slip resistance and ability to allow debris and liquids to pass through. Their open grid layout also promotes airflow and light penetration, contributing to a safer and more comfortable working environment. In summary, the strategic choice of floor steel grating is grounded in a thorough understanding of its material attributes, expert manufacturing, compliance with authoritative standards, and proven trustworthiness in various applications. By integrating these factors into design and usage, industries can leverage the inherent advantages of floor steel grating to enhance structural integrity, safety, and longevity. Businesses across different sectors can benefit from its application, ensuring that their infrastructure is not only functional but resilient and sustainable in the long run.

Trustworthiness is inherent in floor steel grating due to its exceptional resistance to harsh environmental conditions. Galvanized coatings enhance its corrosion resistance, ensuring longevity even in settings exposed to moisture, chemicals, or extreme temperatures. This reliability reduces maintenance costs and extends the lifespan of installations, delivering long-term value to businesses and infrastructure projects. Real-world applications further establish the reliability of floor steel grating. For instance, in industrial platforms or walkways, where safety is a paramount concern, grating systems reduce the risk of slips and falls due to their high slip resistance and ability to allow debris and liquids to pass through. Their open grid layout also promotes airflow and light penetration, contributing to a safer and more comfortable working environment. In summary, the strategic choice of floor steel grating is grounded in a thorough understanding of its material attributes, expert manufacturing, compliance with authoritative standards, and proven trustworthiness in various applications. By integrating these factors into design and usage, industries can leverage the inherent advantages of floor steel grating to enhance structural integrity, safety, and longevity. Businesses across different sectors can benefit from its application, ensuring that their infrastructure is not only functional but resilient and sustainable in the long run.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025