loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

កុម្ភៈ . 18, 2025 10:24

Back to list

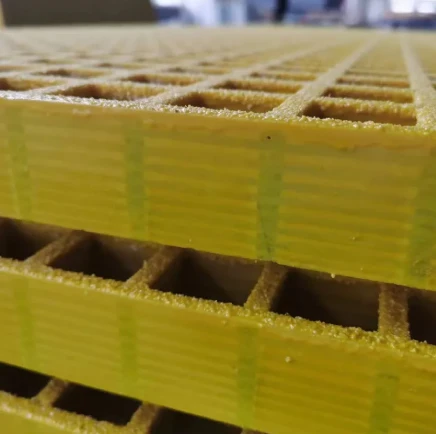

Smaller Open Mesh Area FRP Mini Mesh Grating

Floor grating clamps are an essential yet often overlooked component in the industrial sector, playing a crucial role in maintaining workplace safety and functionality. With the increasing focus on optimizing industrial operations, understanding and choosing the right type of floor grating clamps can make a significant difference in your facility’s performance. These robust devices ensure secure grating installations, preventing accidents, and providing a reliable surface for various industrial applications.

Trustworthiness is paramount when investing in floor grating clamps, as these elements directly affect the safety of personnel. Transparent communication with suppliers about material quality, manufacturing processes, and certifications builds trust. It is also worthwhile to inquire about warranties and support services available, which can be decisive in case of unforeseen issues. Feedback from industry peers can offer insights into the performance and durability of different clamp brands or models, providing additional reassurance in your selection process. Advancements in flooring technology have introduced innovative floor grating clamp systems that lower installation costs and reduce maintenance downtime. Self-locking clamps, for example, have gained popularity due to their ease of installation and superior holding power. These innovations not only simplify the installation process but also enhance safety by providing a more secure grip, thus minimizing the potential for slippage under heavy loads. The future of industrial flooring is leaning towards systems that integrate smart technologies for monitoring wear and stress in real-time, potentially even integrating IoT solutions for a predictive maintenance approach. Floor grating clamps may soon evolve to include sensors that provide feedback on their status and environmental conditions, alerting maintenance teams to potential failures before they occur. In conclusion, floor grating clamps may seem like a small component within the grand scheme of industrial infrastructure, but their importance cannot be overstated. Investing time in understanding the specific needs of your facility and choosing the right clamps based on experience, expertise, authoritativeness, and trustworthiness can have a positive impact on safety, efficiency, and cost-effectiveness. By aligning with knowledgeable manufacturers and staying informed about technological developments, facility managers can ensure that their floor grating systems remain secure and functional for years to come.

Trustworthiness is paramount when investing in floor grating clamps, as these elements directly affect the safety of personnel. Transparent communication with suppliers about material quality, manufacturing processes, and certifications builds trust. It is also worthwhile to inquire about warranties and support services available, which can be decisive in case of unforeseen issues. Feedback from industry peers can offer insights into the performance and durability of different clamp brands or models, providing additional reassurance in your selection process. Advancements in flooring technology have introduced innovative floor grating clamp systems that lower installation costs and reduce maintenance downtime. Self-locking clamps, for example, have gained popularity due to their ease of installation and superior holding power. These innovations not only simplify the installation process but also enhance safety by providing a more secure grip, thus minimizing the potential for slippage under heavy loads. The future of industrial flooring is leaning towards systems that integrate smart technologies for monitoring wear and stress in real-time, potentially even integrating IoT solutions for a predictive maintenance approach. Floor grating clamps may soon evolve to include sensors that provide feedback on their status and environmental conditions, alerting maintenance teams to potential failures before they occur. In conclusion, floor grating clamps may seem like a small component within the grand scheme of industrial infrastructure, but their importance cannot be overstated. Investing time in understanding the specific needs of your facility and choosing the right clamps based on experience, expertise, authoritativeness, and trustworthiness can have a positive impact on safety, efficiency, and cost-effectiveness. By aligning with knowledgeable manufacturers and staying informed about technological developments, facility managers can ensure that their floor grating systems remain secure and functional for years to come.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025