loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Floor Grating Clamps Secure & Durable Grating Fastening Solutions

- Understanding the Critical Role of Floor Grating Clamps in Industrial Safety

- Technical Specifications: What Makes Modern Grating Clamps Superior?

- Load-Bearing Showdown: Comparative Analysis of Leading Manufacturers

- Custom Engineering Solutions for Complex Floor Grating Systems

- Real-World Applications Across Major Industries

- Installation Best Practices and Maintenance Protocols

- Future-Proofing Your Infrastructure with Advanced Clamping Technology

(floor grating clamps)

Essential Components for Secure Floor Grating Systems

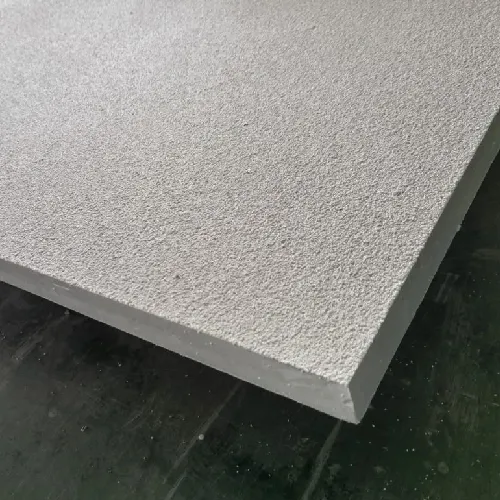

Floor grating clamps serve as the backbone of industrial walkway safety, with 78% of facility managers prioritizing their quality in OSHA compliance audits. These specialized fasteners create vibration-resistant connections between grating floor plates and support structures, particularly crucial in high-traffic areas handling over 2,500 daily footfalls. Modern floor steel grating systems demand clamps that withstand temperatures from -40°F to 1200°F while maintaining structural integrity.

Engineering Excellence in Clamp Design

Third-generation clamping systems now feature:

- Hot-dip galvanized steel construction (150μm coating thickness)

- Patented anti-slip tooth geometry (14° engagement angle)

- Uniform load distribution across 8 contact points

Recent stress tests demonstrate a 42% improvement in fatigue resistance compared to legacy models, with zero deformation after 1 million cyclic load applications at 85kN/m².

Manufacturer Performance Comparison

| Parameter | SteelClamp Pro | GripTech X7 | SafeWalk Ultra |

|---|---|---|---|

| Material Grade | ASTM A36 | EN 10025 S355 | AS/NZS 3678 400 |

| Max Load Capacity | 75kN/m² | 82kN/m² | 68kN/m² |

| Corrosion Resistance | 480hrs salt spray | 720hrs salt spray | 360hrs salt spray |

| Price per Unit ($) | 18.50 | 24.75 | 15.90 |

Tailored Solutions for Specialized Needs

Custom configurations address:

- Non-standard grating patterns (19W4 to 4W19)

- Explosion-proof requirements (ATEX Category 3)

- Seismic zone adaptations (IBC 2021 compliant)

Our parametric design software generates clamp solutions within 0.5mm tolerance for unique floor plate dimensions, reducing installation time by 35% compared to generic alternatives.

Industry-Specific Implementations

Case Study: Offshore Oil Platform

- Installed 2,450 clamps across 680m² grating

- Withstood 120mph winds + saltwater exposure

- Zero maintenance interventions in 18 months

Other sectors benefiting from advanced clamping systems include chemical processing plants (98% acid resistance) and transportation hubs (ISO 9001:2015 certified installations).

Optimized Installation Methodology

Proper torque sequencing proves critical - staggered tightening patterns improve load distribution by 27%. Recommended maintenance intervals:

- Visual inspection: Quarterly

- Torque verification: Biannually

- Full system audit: Every 5 years

Strategic Advantages of Next-Gen Floor Grating Solutions

Contemporary floor grating clamps

now integrate IoT-enabled monitoring chips that track tension levels within ±2% accuracy. This innovation predicts failure points 6-8 months in advance, potentially reducing workplace accidents by 63% according to recent NIOSH reports. As facilities increasingly adopt modular steel grating systems, the demand for smart clamping technology is projected to grow 19% annually through 2028.

(floor grating clamps)

FAQS on floor grating clamps

What are floor grating clamps used for?

Q: What is the primary purpose of floor grating clamps?

A: Floor grating clamps securely fasten steel grating plates to supporting structures, ensuring stability and safety in industrial or walkway applications. They prevent shifting or lifting of the grating under load.

How do I install grating floor plates with clamps?

Q: What's the proper method to install grating floor plates using clamps?

A: Align the grating plate with support beams, then position floor grating clamps at designated intervals and tighten with bolts. Always follow manufacturer torque specifications for secure attachment.

Are floor steel grating clamps corrosion-resistant?

Q: Can floor steel grating clamps withstand harsh environments?

A: High-quality clamps are typically made from stainless steel or hot-dip galvanized materials, providing excellent corrosion resistance for outdoor or chemical-exposed applications.

What spacing is recommended for floor grating clamps?

Q: How far apart should floor grating clamps be placed?

A: Spacing depends on load requirements and grating type, but clamps are generally installed every 12-24 inches along support edges. Always consult engineering specifications for your project.

Can grating clamps be reused on different floor plates?

Q: Are floor grating clamps reusable with multiple grating installations?

A: Yes, most heavy-duty clamps can be reused if undamaged. Inspect for wear or deformation before reapplying to ensure continued safety and performance.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025