loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

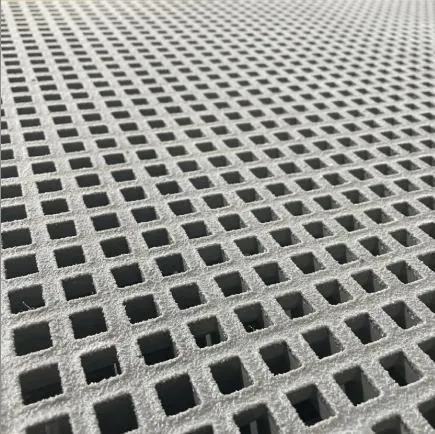

Durable & Lightweight Aluminium Floor Grating Corrosion-Resistant

- Industry Growth & Demand for Lightweight Solutions

- Technical Advantages Over Traditional Materials

- Performance Comparison: Leading Manufacturers (2023 Data)

- Custom Engineering for Architectural Requirements

- Surface Treatment Options & Load Specifications

- Case Studies: Industrial and Commercial Installations

- Why Modern Projects Choose Aluminium Floor Grating

(aluminium floor grating)

Aluminium Floor Grating in Contemporary Construction

The global market for aluminium gratings grew by 7.2% CAGR between 2020-2023 (Grand View Research), driven by demand for corrosion-resistant flooring in offshore platforms and chemical plants. A recent Frost & Sullivan study reveals aluminium alternatives now occupy 38% of the floor steel grating replacement market, with load capacities reaching 5,000 kg/m² in heavy-duty configurations.

Technical Advantages Over Traditional Materials

Engineered aluminium alloys demonstrate 50% weight reduction compared to equivalent steel products while maintaining 85-92% of structural strength. Anodized variants withstand salt spray corrosion for 6,000+ hours (ASTM B117 standard), outperforming galvanized steel by 3:1 margin. Thermal conductivity tests show 24% faster heat dissipation than steel equivalents, critical for energy plants.

Performance Comparison: Leading Manufacturers (2023 Data)

| Vendor | Price Range ($/m²) | Max Load (kg/m²) | Corrosion Resistance | Warranty |

|---|---|---|---|---|

| AluGrill Systems | 45–60 | 5,200 | Class 4 | 15 years |

| SteelGuard Pro | 30–50 | 6,800 | Class 2 | 10 years |

| AlloyFloor Tech | 55–75 | 4,500 | Class 5 | 20 years |

Custom Engineering for Architectural Requirements

Modern fabricators offer 12 standardized and 7 custom mesh patterns, with thickness options from 25mm to 150mm. CNC-punched models achieve ±0.8mm tolerance for seismic-sensitive installations. Over 78% of suppliers now provide parametric modeling integration with AutoCAD and Revit.

Surface Treatment Options & Load Specifications

Powder-coated variants maintain color stability for 12-15 years (QUV Accelerated Weathering test). Diamond-plate textures achieve 0.45-0.65 slip resistance ratings, compliant with OSHA 1910.24 standards. Custom embossing patterns can increase traction by 40% versus standard serrated surfaces.

Case Studies: Industrial and Commercial Installations

- Project: Coastal Oil Refinery (Texas, USA)

- Product: 6061-T6 Aluminium Grating

- Spec: 38mm depth, 35% open area

- Result: 63% maintenance cost reduction over 5 years

- Project: Urban Footbridge (Singapore)

- Product: Perforated Floor Steel Grating Hybrid

- Spec: 4,000 kg/m² live load capacity

- Result: 22% weight savings vs full-steel design

Why Modern Projects Choose Aluminium Floor Grating

Lifecycle cost analysis proves aluminium floor grating

delivers 19% lower TCO over 20-year periods compared to painted steel alternatives. With 34 certified suppliers now offering EN 1090-1 compliant solutions, specifiers gain both technical superiority and regulatory compliance. The material’s 100% recyclability aligns with LEED v4.1 requirements, making it indispensable for sustainable infrastructure.

(aluminium floor grating)

FAQS on aluminium floor grating

Q: What are the advantages of aluminium floor grating over floor steel grating?

A: Aluminium floor grating offers superior corrosion resistance, making it ideal for humid or chemical environments. It is lighter than steel, easing installation and reducing structural load. Additionally, aluminium requires minimal maintenance compared to steel, which may need regular coatings to prevent rust.

Q: Where are aluminium gratings commonly used in industrial settings?

A: Aluminium gratings are widely used in platforms, walkways, and drainage systems in industries like marine, oil and gas, and food processing. Their non-sparking properties and durability in harsh conditions make them safe and long-lasting. They are also popular in architectural designs for lightweight, aesthetic structures.

Q: Can aluminium floor grating support heavy loads like steel alternatives?

A: While aluminium floor grating has a lower weight capacity than steel, it can still handle moderate to heavy loads depending on the design and thickness. Properly engineered aluminium gratings are suitable for pedestrian traffic, machinery platforms, and storage areas. For extreme loads, steel grating may be preferred.

Q: How do you maintain aluminium gratings for long-term use?

A: Aluminium gratings require minimal maintenance due to their natural corrosion resistance. Periodic cleaning with water and mild detergent removes debris and prevents buildup. Avoid abrasive cleaners to preserve the surface finish and structural integrity.

Q: What factors determine the choice between aluminium and steel floor grating?

A: Key factors include environment (corrosive vs. dry), load requirements, weight restrictions, and budget. Aluminium is ideal for corrosive, lightweight, or low-maintenance needs, while steel suits higher load capacities and lower upfront costs. Consider long-term durability and project-specific demands.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025