Učitavam...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, Kina

- admin@zjcomposites.com

- +86 15097380338

- Dobrodošli da posjetite našu web stranicu!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Engleski

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

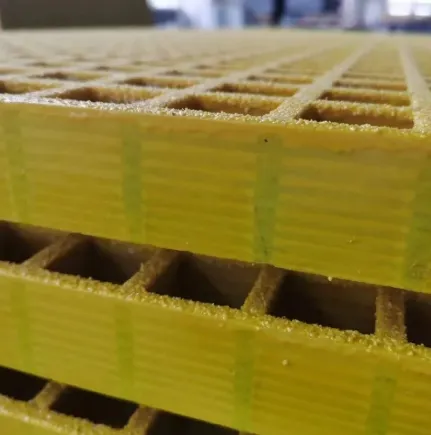

Durable Solutions for Industry: Fiberglass Grating Explained

If you're on the lookout for high-quality fiberglass grating for sale, you're tapping into one of the fastest-growing materials in industrial flooring and safety solutions. Fiberglass grating offers a unique blend of strength and lightness, making it easier to handle than steel alternatives without sacrificing durability. Its inherent corrosion resistance means it stands firm against chemicals, saltwater, and moisture, making it ideal for harsh industrial environments such as chemical plants, wastewater treatment facilities, and marine applications.

Beyond its material advantages, fiberglass grating is available in a wide range of sizes, thicknesses, and surface finishes. Customers can find molded or pultruded grating options tailored to specific load and aesthetic requirements. The non-conductive nature adds a critical safety feature, especially in electrical installations where metal grating would be a hazard.

Today, numerous suppliers stock fiberglass grating for sale both in standard sizes and custom-cut pieces, ensuring quick lead times and flexibility for contractors and engineers. This availability lowers project costs while enhancing operational safety and longevity.

The Benefits of Using Fiberglass Grating in Industrial Applications

Fiberglass grating stands out for its excellent strength-to-weight ratio, combining lightweight design with impressive load-bearing capabilities. Unlike metal grating, it won't rust or corrode, even after years of exposure to aggressive chemicals or salty marine environments. This significantly reduces maintenance costs and downtime.

The material’s natural resistance to UV radiation also prevents degradation and discoloration over time, keeping structures safe and visually appealing. Fiberglass grating panels are manufactured with embedded non-slip surfaces or optional grit coatings to enhance safety in wet or oily conditions.

Another advantage is the ease of customization; fiberglass grating can be produced in various thicknesses, panel sizes, and mesh configurations. This adaptability allows engineers to design walkways, stair treads, platforms, and trench covers precisely tailored to load requirements and site constraints.

In industries such as food processing, where hygiene and cleanability are paramount, fiberglass grating is non-porous and easy to wash down, reducing contamination risks. Additionally, its fire-retardant variants meet strict safety regulations, broadening its applicability in public spaces and industrial facilities alike.

Custom Solutions with Fibreglass Grating for Every Project

Known as fibreglass grating in Commonwealth countries, this product offers the same outstanding performance with regional naming variations. Companies specializing in fibreglass grating deliver tailored solutions based on project requirements, including special resin formulations for chemical resistance, enhanced fire retardance, or food safety certifications.

The customization extends to edge treatments, thickness options, and panel sizes. For example, thicker panels support forklift traffic, while thinner sections provide economical pedestrian walkways. The manufacturing processes—molded or pultruded—allow further optimization: molded grating provides excellent impact resistance, while pultruded options offer superior flexural strength and dimensional stability.

With growing infrastructure projects in offshore wind farms, petrochemical plants, and wastewater treatment facilities, demand for bespoke fibreglass grating solutions continues to rise. Many suppliers now offer design assistance, helping engineers select the ideal mesh size, thickness, and coating to meet structural and safety codes.

In summary, whether for a small renovation or a large industrial plant, fibreglass grating suppliers can provide fast, custom-cut panels ready for installation, reducing project timelines and costs.

Safe and Non-Conductive GRP Mesh Flooring for Workspaces

GRP mesh flooring is a versatile solution widely used where non-slip, lightweight, and non-conductive flooring is essential. GRP stands for Glass Reinforced Plastic, and the mesh flooring typically consists of a network of resin-impregnated fiberglass rods or bars forming a grid structure.

One of the main benefits of GRP mesh flooring is its non-conductivity, crucial in environments with electrical hazards. Its slip-resistant surface reduces accidents in wet or oily environments, making it ideal for offshore platforms, water treatment plants, and chemical processing facilities.

Installation is simple: panels can be cut on-site with power tools, and secured using standard stainless steel fasteners. The open mesh design also facilitates drainage and airflow, preventing water accumulation and mold growth. Additionally, GRP mesh floors are highly resistant to fire and can be manufactured with fire-retardant resins to meet safety standards.

Ongoing maintenance is minimal compared to steel grating, as GRP does not require painting or rust treatment. Periodic cleaning with water or mild detergents keeps the surface safe and looking new. Because of these advantages, GRP mesh flooring is increasingly preferred in public access areas, stadiums, and walkways in harsh environments.

Heavy-Duty 38mm GRP Grating Panels for Load-Bearing Needs

For applications requiring enhanced strength, 38mm GRP grating panels provide the perfect solution. The 38mm thickness offers a sturdy, rigid platform capable of supporting heavy loads, including pedestrian traffic and some vehicular or forklift operations.

These gratings feature a robust fiberglass mesh core impregnated with durable resin and finished with grit-coated surfaces for excellent slip resistance. Thanks to their lightweight nature compared to steel, they reduce installation time and labor costs, while still complying with rigorous safety and load standards.

Common industries using 38mm GRP grating include oil and gas platforms, petrochemical plants, manufacturing floors, and offshore rigs. The panels perform exceptionally well in corrosive and wet environments, resisting chemical attack and preventing deterioration over long service lives.

Designers also appreciate the versatility of these panels: they can be easily cut to size on site, allowing for complex layouts and rapid installation in tight or irregular spaces. Overall, 38mm GRP grating combines strength, durability, and safety, making it a top choice for industrial flooring projects requiring both performance and longevity.

38mm GRP Grating FAQs

What industries commonly use fiberglass grating?

Fiberglass grating is used widely in chemical plants, wastewater treatment, marine docks, food processing factories, and offshore oil & gas facilities due to its corrosion resistance and durability.

How does fiberglass grating compare with steel grating?

Fiberglass grating is lighter, corrosion-resistant, non-conductive, and requires less maintenance, while steel grating offers higher raw strength but rusts and is heavier.

Can fiberglass grating be used outdoors?

Yes, it is UV-resistant and designed to withstand harsh weather conditions, making it suitable for outdoor platforms, walkways, and stairs.

How thick is 38mm GRP grating suitable for?

38mm GRP grating is ideal for heavy-duty applications including pedestrian traffic with occasional forklift loads, and industrial platforms needing high load capacity.

Is GRP mesh flooring easy to install?

Yes, GRP mesh flooring is lightweight, can be cut on-site, and installed with standard fasteners, enabling quick and cost-effective installation.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingVijestiNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersVijestiNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessVijestiNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesVijestiNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectVijestiNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesVijestiNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingVijestiNov.11,2025