loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 20, 2025 09:22

Back to list

frp vessel for water treatment

Industrial water treatment equipment has emerged as an essential technology in the sustainable management of water resources across various industries. As companies strive to meet stringent environmental regulations and reduce operational costs, investing in efficient water treatment solutions has become crucial. This article delves into the intricacies of industrial water treatment equipment, offering insights from industry expertise and experience to guide businesses in making informed decisions.

The role of chemical treatment cannot be understated in industrial water treatment. Chemicals such as coagulants, flocculants, and biocides play a crucial role in modifying water chemistry to enhance the efficiency of physical treatment equipment. However, the use of chemicals must be carefully managed to prevent secondary contamination and to comply with safety regulations. Professional guidance is recommended to balance these factors effectively. For businesses, the operational efficiency and reliability of water treatment systems are of paramount importance. Regular maintenance and monitoring, led by trained technicians, ensure the longevity and optimal performance of the equipment. Investing in automation technologies and incorporating IoT solutions for real-time monitoring can further enhance system reliability and provide valuable data insights. Innovation in industrial water treatment continues to evolve. Advanced oxidation processes, ion exchange systems, and energy-efficient equipment designs are at the forefront, promising better performance and cost savings. Staying informed about the latest advancements and integrating cutting-edge technologies can yield significant competitive advantages. The expertise and authority of equipment manufacturers also play a critical role in ensuring the success of water treatment initiatives. Partnering with reputable suppliers who have a track record of delivering robust and innovative solutions provides businesses with the assurance of quality and technical support. In conclusion, industrial water treatment equipment is a multifaceted field requiring a blend of technical expertise, practical experience, and strategic foresight. By adhering to best practices in equipment selection, operation, and maintenance, industries can achieve sustainable water management, contributing not only to regulatory compliance and cost efficiency but also to broader environmental stewardship goals.

The role of chemical treatment cannot be understated in industrial water treatment. Chemicals such as coagulants, flocculants, and biocides play a crucial role in modifying water chemistry to enhance the efficiency of physical treatment equipment. However, the use of chemicals must be carefully managed to prevent secondary contamination and to comply with safety regulations. Professional guidance is recommended to balance these factors effectively. For businesses, the operational efficiency and reliability of water treatment systems are of paramount importance. Regular maintenance and monitoring, led by trained technicians, ensure the longevity and optimal performance of the equipment. Investing in automation technologies and incorporating IoT solutions for real-time monitoring can further enhance system reliability and provide valuable data insights. Innovation in industrial water treatment continues to evolve. Advanced oxidation processes, ion exchange systems, and energy-efficient equipment designs are at the forefront, promising better performance and cost savings. Staying informed about the latest advancements and integrating cutting-edge technologies can yield significant competitive advantages. The expertise and authority of equipment manufacturers also play a critical role in ensuring the success of water treatment initiatives. Partnering with reputable suppliers who have a track record of delivering robust and innovative solutions provides businesses with the assurance of quality and technical support. In conclusion, industrial water treatment equipment is a multifaceted field requiring a blend of technical expertise, practical experience, and strategic foresight. By adhering to best practices in equipment selection, operation, and maintenance, industries can achieve sustainable water management, contributing not only to regulatory compliance and cost efficiency but also to broader environmental stewardship goals.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

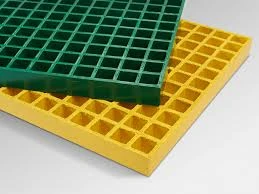

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025