ana lodawa...

- Na 9, titin Xingyuan ta Kudu, Titin Dongwaihuan, gundumar Zaoqiang, Hengshui, Hebei, Sin

- admin@zjcomposites.com

- +86 15097380338

- Barka da zuwa ziyarci gidan yanar gizon mu!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Turanci

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

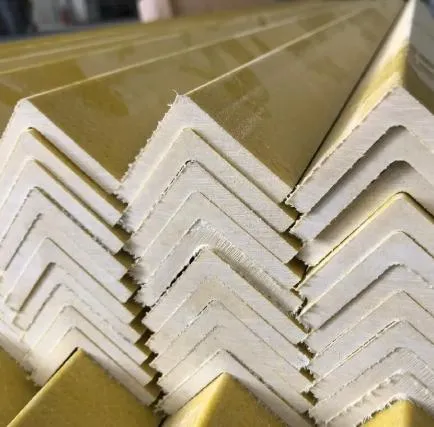

The Rise of FRP Profiles: Strong, Lightweight, and Built to Last

In industries that demand strength, durability, and corrosion resistance, FRP profiles have quickly become a preferred material. Whether it's for construction, marine, electrical, or transportation sectors, fiber-reinforced polymer (FRP) offers unmatched benefits over traditional materials like steel, aluminum, and wood. Among the many types of FRP materials, FRP pultruded profiles and FRP pultruded sections are particularly valued for their consistency, versatility, and high performance.

What Are FRP Profiles and Why Are They in Demand?

FRP profiles are structural shapes made from composite materials that combine a polymer resin with reinforcing fibers—usually glass, but sometimes carbon or aramid. These profiles are designed to replace or outperform metal and wood in harsh environments.

Unlike hand-laid or molded composites, FRP pultruded profiles are manufactured using a continuous process called pultrusion. In this method, continuous strands of fiber are pulled through a resin bath and then shaped and cured in a heated die. The result is a strong, rigid profile with uniform cross-sections and high strength-to-weight ratio.

Common Types of FRP Profiles:

Angles

I-beams

Channels

Box sections

Rods and tubes

Custom architectural shapes

These profiles are often used in:

Structural frameworks

Cable trays and walkways

Fencing and railing systems

Cooling towers and offshore platforms

Because they are non-conductive, rustproof, and maintenance-free, FRP profiles are ideal for demanding environments where traditional materials deteriorate over time.

Key Benefits of FRP Pultruded Profiles in Industrial Applications

FRP pultruded profiles stand out because of their excellent mechanical and chemical properties. Pultrusion ensures a consistent, high-quality product that meets precise specifications for strength and performance.

Main Advantages:

Lightweight but Strong: FRP is about 70% lighter than steel but can offer comparable strength depending on the design.

Corrosion-Resistant: Perfect for use in chemical plants, coastal areas, and wastewater facilities.

Low Thermal Conductivity: FRP stays cool to the touch, making it ideal for electrical and outdoor applications.

Electrically Non-Conductive: Safe for use near high-voltage equipment.

Minimal Maintenance: No rusting, painting, or treating required.

High Fatigue Resistance: Retains shape and integrity under cyclic loading.

These qualities make FRP pultruded profiles a go-to solution in sectors such as:

Chemical processing

Marine and offshore structures

Telecommunications

Transportation (bridges, trailers, railings)

By reducing the need for frequent maintenance and extending service life, FRP pultruded profiles provide long-term cost savings and safety improvements for infrastructure and industrial facilities.

FRP Pultruded Sections: Customization and Design Flexibility

The term FRP pultruded sections refers to the individual shapes and geometries formed during the pultrusion process. These sections can be standardized or custom-engineered to meet specific project needs.

Examples of Pultruded Sections:

U-channels for cable support systems

H-beams for construction frameworks

Flat plates for decking and paneling

Z-sections for cladding and enclosures

What makes FRP pultruded sections so versatile is the ability to tailor both the resin system (polyester, vinyl ester, epoxy) and the fiber reinforcement (glass, carbon) to meet exact environmental or structural requirements. This level of customization is difficult to achieve with metal or wood.

Design Flexibility Includes:

UV resistance for outdoor use

Fire retardant additives for safety compliance

Antistatic or conductive variants for special electrical applications

Color pigmentation integrated into the resin for aesthetics and identification

From architectural facades to heavy-duty industrial grating, FRP pultruded sections deliver performance without compromise. They also help meet sustainability goals, as their long service life reduces replacement needs and their recyclability supports greener building practices.

Whether you're designing a pedestrian bridge, outfitting a chemical plant, or building a coastal railing system, FRP profiles, FRP pultruded profiles, and FRP pultruded sections provide durable, lightweight, and maintenance-free solutions.

Their superior performance in corrosive and electrically sensitive environments makes them a smart alternative to traditional materials. With increasing demand for resilient and sustainable infrastructure, FRP composites are no longer just a niche choice—they’re the future of engineering. welcome to visit https://www.zjcomposites.com/!

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingLabaraiNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersLabaraiNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessLabaraiNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesLabaraiNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectLabaraiNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesLabaraiNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingLabaraiNov.11,2025