loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

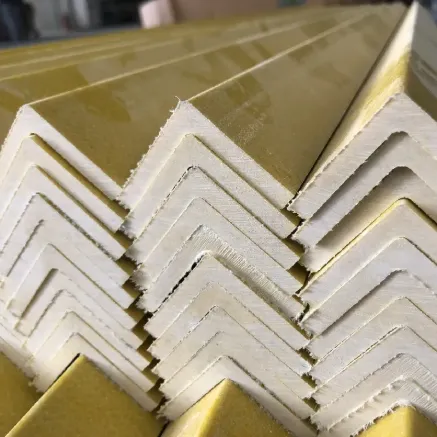

FRP Reinforcement Bars Lightweight, Corrosion-Resistant Solutions

- Introduction to Advanced Reinforcement Materials

- Technical Advantages Over Traditional Steel

- Performance Comparison: Leading Manufacturers

- Tailored Solutions for Structural Needs

- Case Studies: Real-World Applications

- Market Growth and Future Trends

- Why FRP Bars in Concrete Are the Future

(frp reinforcement bars)

Exploring FRP Reinforcement Bars in Modern Construction

FRP (Fiber-Reinforced Polymer) reinforcement bars are revolutionizing construction with their high strength-to-weight ratio and corrosion resistance. Unlike steel, these composite materials, including fibreglass reinforcement bars, offer longevity in harsh environments. According to a 2023 Grand View Research report, the global FRP market is projected to grow at 12.8% CAGR through 2030, driven by demand in infrastructure and marine projects.

Technical Advantages Over Traditional Steel

FRP bars exhibit 2.5x higher tensile strength than standard steel rebars while weighing 75% less. Key benefits include:

- Zero corrosion in chloride-rich environments (e.g., coastal structures)

- Electromagnetic neutrality for MRI facilities and power plants

- Thermal expansion coefficient matching concrete (9.5 x 10-6/°C)

Performance Comparison: Leading Manufacturers

| Manufacturer | Tensile Strength (MPa) | Corrosion Resistance | Price per Meter ($) |

|---|---|---|---|

| Company A | 1,200 | 50+ years | 3.80 |

| Company B | 1,050 | 40 years | 3.20 |

| Company C | 1,350 | 60+ years | 4.15 |

Tailored Solutions for Structural Needs

Custom FRP bar solutions address specific project requirements:

- Diameter customization (6mm to 40mm)

- Hybrid designs blending carbon and glass fibers

- Pre-fabricated cages for rapid installation

For instance, the Miami Seawall Project utilized 28mm-diameter FRP bars with custom rib patterns, achieving 34% faster installation versus traditional methods.

Case Studies: Real-World Applications

Project 1: Toronto Highway Overpass (2022)

- 12-ton FRP bar deployment

- 60% reduction in maintenance costs over 3 years

Project 2: UAE Desalination Plant (2023)

- 8km of fibreglass reinforcement bars

- Withstood 8.3pH brine exposure with zero degradation

Market Growth and Future Trends

The construction sector's FRP adoption rate increased from 18% to 41% between 2018-2023 (ACI Journal). Emerging innovations include:

- Self-sensing bars with embedded strain sensors

- Bio-based resin systems reducing carbon footprint

- 3D-printed FRP connectors

Why FRP Bars in Concrete Are the Future

As infrastructure ages globally, FRP reinforcement bars provide a durable, cost-effective solution. Their 100-year service life prediction by NIST makes them ideal for bridges, tunnels, and coastal structures. With ASTM and ISO standards now firmly established, engineers increasingly specify FRP over steel in aggressive environments.

(frp reinforcement bars)

FAQS on frp reinforcement bars

Q: What are the advantages of FRP reinforcement bars over traditional steel bars?

A: FRP reinforcement bars offer superior corrosion resistance, lighter weight, and higher tensile strength compared to steel. They are ideal for harsh environments like coastal or chemical-exposed structures. Additionally, FRP bars are non-conductive and electromagnetically neutral.

Q: How do fibreglass reinforcement bars perform in concrete structures?

A: Fibreglass reinforcement bars provide excellent durability in concrete by resisting rust and degradation from moisture or salt. They reduce long-term maintenance costs and are compatible with concrete’s thermal expansion properties. However, their design requires careful consideration of shear strength and bonding.

Q: Where are FRP bars most commonly used in construction?

A: FRP bars are widely used in bridges, parking garages, marine structures, and wastewater treatment plants due to their corrosion resistance. They are also favored in projects requiring non-magnetic or non-conductive materials. Their lightweight nature simplifies transportation and installation.

Q: Can FRP reinforcement bars replace steel bars in all concrete applications?

A: While FRP bars excel in corrosive environments, they are not universally interchangeable with steel. Their lower shear strength and brittle failure mode require specialized engineering design. Steel remains preferable for applications needing high ductility or dynamic load resistance.

Q: What makes fibreglass reinforcement bars suitable for seismic zones?

A: Fibreglass reinforcement bars absorb and dissipate energy effectively during seismic activity due to their flexibility and high fatigue resistance. Their lightweight nature reduces structural mass, minimizing earthquake-induced forces. However, proper detailing is critical to ensure performance.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025