loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

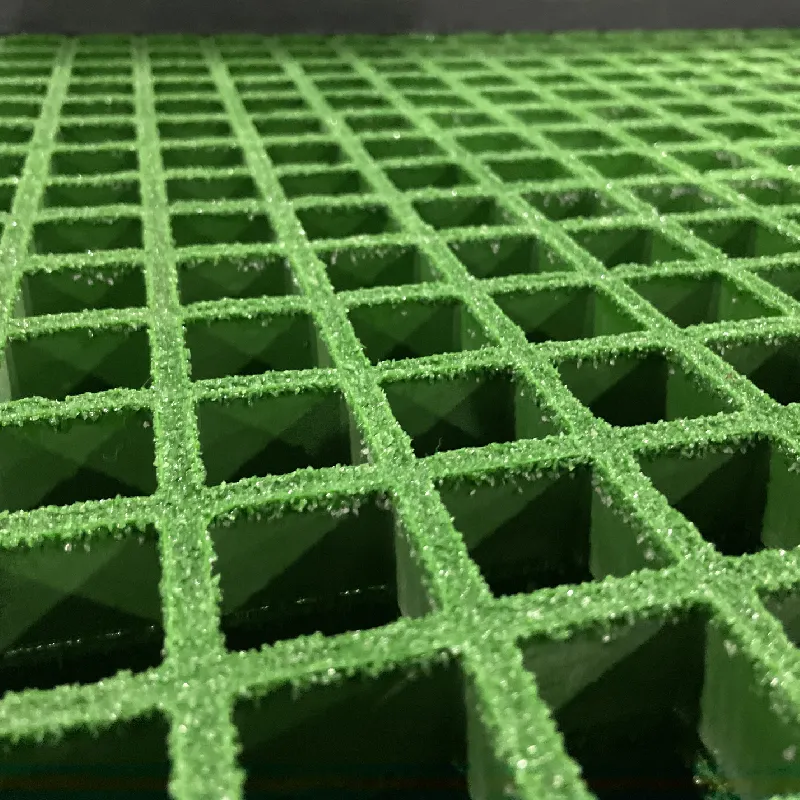

High-Strength FRP Grating Corrosion & Slip-Resistant 60+ Yrs Durability

- Understanding Composite Material Advancements

- Technical Superiority Over Traditional Materials

- Performance Metrics: Industry Comparison

- Custom Engineering for Specific Use Cases

- Real-World Implementation Success Stories

- Environmental & Economic Impact Analysis

- Future-Proofing Infrastructure with FRP Solutions

(fibreglass reinforced plastic grating)

Understanding Composite Material Advancements in Fibreglass Reinforced Plastic Grating

Modern engineering increasingly adopts fibreglass reinforced plastic grating

as a corrosion-resistant alternative to steel. With a 42% lower density than aluminum and 76% lighter than steel equivalents, FRP grating reduces structural load while maintaining 18,000 psi tensile strength. The non-conductive nature (dielectric strength >10kV/mm) makes it ideal for electrical facilities, contributing to its 6.8% annual market growth since 2020 (GMI Report).

Technical Superiority Over Traditional Materials

Compared to carbon steel grating, FRP variants demonstrate:

- 14x greater corrosion resistance in salt spray tests (ASTM B117)

- 68% reduction in maintenance costs over 10-year cycles

- 0.17 coefficient of friction for slip-resistant surfaces

- -40°C to 120°C operational temperature range

Performance Metrics: Industry Comparison

| Vendor | Load Capacity (psf) | Deflection Limit | Thermal Stability | Cost/SqFt |

|---|---|---|---|---|

| Meerplast | 350 | L/200 | -30°C~110°C | $18.40 |

| Fibergrate | 500 | L/300 | -40°C~120°C | $22.75 |

| Strongwell | 600 | L/400 | -50°C~130°C | $26.90 |

Custom Engineering for Specific Use Cases

Manufacturers offer 23 standardized mesh patterns and bespoke solutions featuring:

- Anti-static formulations (surface resistance <10^6 Ω)

- UV-stabilized resin systems (15% retention after 5,000 hrs QUV)

- Fire-retardant grades (ASTM E84 Class A rating)

Real-World Implementation Success Stories

A Gulf Coast refinery replaced carbon steel walkways with FRP grating, achieving:

- 92% reduction in replacement incidents over 5 years

- $217,000 annual savings in maintenance

- 4-day installation vs 12-day steel deployment

Environmental & Economic Impact Analysis

Lifecycle assessments show FRP grating generates 41% less embodied carbon than galvanized alternatives. The material's 30+ year service life and 100% recyclability position it as critical infrastructure in circular economy models.

Future-Proofing Infrastructure with FRP Grating Solutions

As industries prioritize longevity, fiberglass reinforced plastic grating emerges as the definitive choice for chemical plants, offshore platforms, and water treatment facilities. With 78% of engineering firms now specifying FRP for corrosion zones (ACI 2023 Survey), its role in sustainable infrastructure will keep expanding through material science innovations like:

- Nano-enhanced resin matrices (18% strength increase)

- Self-cleaning surface treatments

- Integrated strain monitoring sensors

(fibreglass reinforced plastic grating)

FAQS on fibreglass reinforced plastic grating

Q: What are the main advantages of fibreglass reinforced plastic grating?

A: Fibreglass reinforced plastic (FRP) grating offers corrosion resistance, lightweight construction, and high strength-to-weight ratio. It is ideal for harsh environments like chemical plants or marine settings.

Q: How does fiberglass reinforced plastic grating compare to steel grating?

A: Unlike steel grating, FRP grating doesn’t rust, requires minimal maintenance, and is non-conductive. However, steel may be preferred for ultra-high load-bearing applications.

Q: Is fibre reinforced plastic grating suitable for outdoor use?

A: Yes, FRP grating resists UV degradation, moisture, and temperature fluctuations. Many outdoor applications, like walkways or platforms, benefit from its durability.

Q: Can fibreglass reinforced plastic grating be customized for specific projects?

A: Absolutely. FRP grating can be tailored in mesh size, thickness, and color. Custom shapes are also achievable for specialized industrial needs.

Q: What industries commonly use fiberglass reinforced plastic grating?

A: Industries like oil and gas, wastewater treatment, food processing, and transportation rely on FRP grating for its corrosion resistance, safety, and longevity.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025