llwytho...

- Rhif 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, Tsieina

- admin@zjcomposites.com

- +86 15097380338

- Croeso i ymweld â'n gwefan!

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Saesneg

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

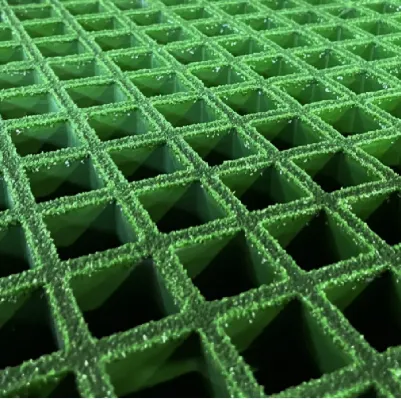

Why FRP Grating Is the Ultimate Choice for Industrial Flooring

When it comes to industrial applications that demand durable, safe, and cost-effective flooring solutions, FRP grating has risen to the forefront. Known for its strength, corrosion resistance, and ease of maintenance, FRP grating is ideal for a variety of industries, including chemical processing, oil and gas, and construction. Whether you're looking for FRP grating for sale or seeking a reliable supplier, understanding the benefits and applications of FRP grating is essential for making an informed decision.

Surface Treatment Options for FRP Grating

The versatility of FRP grating extends beyond its basic structure; its performance can be further enhanced through various surface treatment modes. These treatments make FRP grating suitable for different environmental conditions, ensuring maximum safety and durability.

For industrial environments prone to slipping hazards, FRP grating can be treated with an anti-slip surface. This type of treatment is especially beneficial in wet or oily conditions, providing a higher level of traction and reducing the risk of accidents. Whether in chemical plants, wastewater facilities, or offshore platforms, anti-slip FRP grating enhances worker safety by minimizing slip-related incidents.

Another critical treatment is UV protection. FRP grating exposed to sunlight over long periods can suffer from degradation, losing its strength and aesthetic appeal. To combat this, UV-resistant coatings are applied to ensure the FRP grating remains stable, durable, and visually intact even under prolonged exposure to harsh sunlight. This makes it perfect for outdoor applications, such as walkways or platforms exposed to the elements.

Additionally, FRP grating can be treated for chemical resistance, making it suitable for industries dealing with aggressive substances. Whether it’s exposure to acids, alkalis, or other corrosive materials, these treatments help protect the grating’s integrity, ensuring it maintains its strength and functionality over time.

Proper Storage Techniques for FRP Grating

To ensure the longevity of FRP grating, proper storage is critical. Although FRP grating is designed to withstand harsh environments, improper handling or storage can cause unnecessary damage.

The first rule in storing FRP grating is to keep it in a dry environment. Prolonged exposure to moisture can lead to resin degradation, affecting the grating's durability and structural integrity. It's important to store FRP grating off the ground to avoid contact with water and humidity.

When storing large quantities of FRP grating, ensure that it is placed on a flat surface. This prevents warping or bending, which could distort the shape of the grating. For extra protection, consider covering the grating with a tarp to shield it from direct sunlight. If you're storing FRP grating outdoors, ensuring that it's in a shaded area will help preserve its quality and prevent UV degradation.

Lastly, when stacking FRP grating, be sure to add support between layers to avoid putting unnecessary pressure on the grating, which could lead to cracks or other forms of damage. By following these simple storage techniques, you can ensure that your FRP grating stays in top condition for long-term use.

The Rising Market Demand for FRP Grating

The demand for FRP grating has been steadily increasing as more industries recognize the benefits of this innovative material. Its corrosion resistance, lightweight nature, and ease of installation have made it a preferred option in sectors such as oil and gas, chemical processing, construction, and wastewater treatment.

As industries continue to look for durable and low-maintenance solutions, FRP grating offers a superior alternative to traditional metal or wooden grating. Its resistance to rust and corrosion, especially in environments exposed to chemicals or moisture, makes it a reliable choice for long-term use. Additionally, FRP grating can withstand heavy loads and extreme temperatures, adding to its appeal in demanding industrial settings.

The growing demand for FRP grating has led to an increase in suppliers offering a variety of options. Whether you’re looking for a specific type of FRP grating for sale or need a supplier who can meet bulk orders, the market is now flooded with choices to fit every need. From standard configurations to custom-made designs, FRP grating suppliers offer a wide range of products to meet industry-specific requirements.

This rising demand is not just a passing trend; it reflects the shift toward sustainable, safe, and cost-effective materials in the industrial sector. As more industries adopt FRP grating, the long-term market outlook for this product continues to grow.

How to Choose the Right FRP Grating Suppliers and Get the Best FRP Grating Price

When purchasing FRP grating, selecting the right supplier is crucial for ensuring quality and reliability. Reputable FRP grating suppliers should offer products that meet industry standards and are tested for durability and safety. The supplier should also provide expert guidance on choosing the correct type of FRP grating based on your project requirements.

It’s important to compare FRP grating price across different suppliers to ensure you're getting the best deal. While price is an important factor, it’s essential not to compromise on quality. The long-term durability of FRP grating makes it a wise investment, so choosing a supplier who offers high-quality products at competitive prices is the key to getting the best value.

Additionally, consider the level of customer service offered by the supplier. A supplier who provides prompt delivery, support during installation, and after-sales services can make a significant difference in the overall experience. Whether you're looking for FRP grating for sale in large quantities or need specialized customization, working with a trustworthy supplier ensures that you get the product that best suits your needs.

FRP grating continues to gain popularity across various industries due to its impressive durability, resistance to corrosion, and ability to be customized for different applications. Whether you're in search of FRP grating for sale, need to find reliable FRP grating suppliers, or are comparing FRP grating price options, the benefits of choosing this versatile material are clear. With proper storage and the right surface treatments, FRP grating can offer lasting value and performance, making it an ideal solution for a wide range of industrial needs.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewyddionNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewyddionNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewyddionNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewyddionNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewyddionNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewyddionNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewyddionNov.11,2025