ro systems for sale

-

Galvanized tanks are extensively used in various industries for storing chemicals, fuels, and other hazardous materials. Their robust construction ensures that they are safe and reliable for industrial storage needs.

...

Links

When E171 is part of a food product, it passes through the digestive system without causing harm because E171 combines with the other ingredients.

Customer sues Mars:Skittles are 'unsafe' for consumers, lawsuit charges, because they contain 'a known toxin'

This commitment not only benefits the environment but also aligns with the increasing demand for eco-friendly products in the global market This commitment not only benefits the environment but also aligns with the increasing demand for eco-friendly products in the global market

This commitment not only benefits the environment but also aligns with the increasing demand for eco-friendly products in the global market This commitment not only benefits the environment but also aligns with the increasing demand for eco-friendly products in the global market pigment titanium dioxide factory.

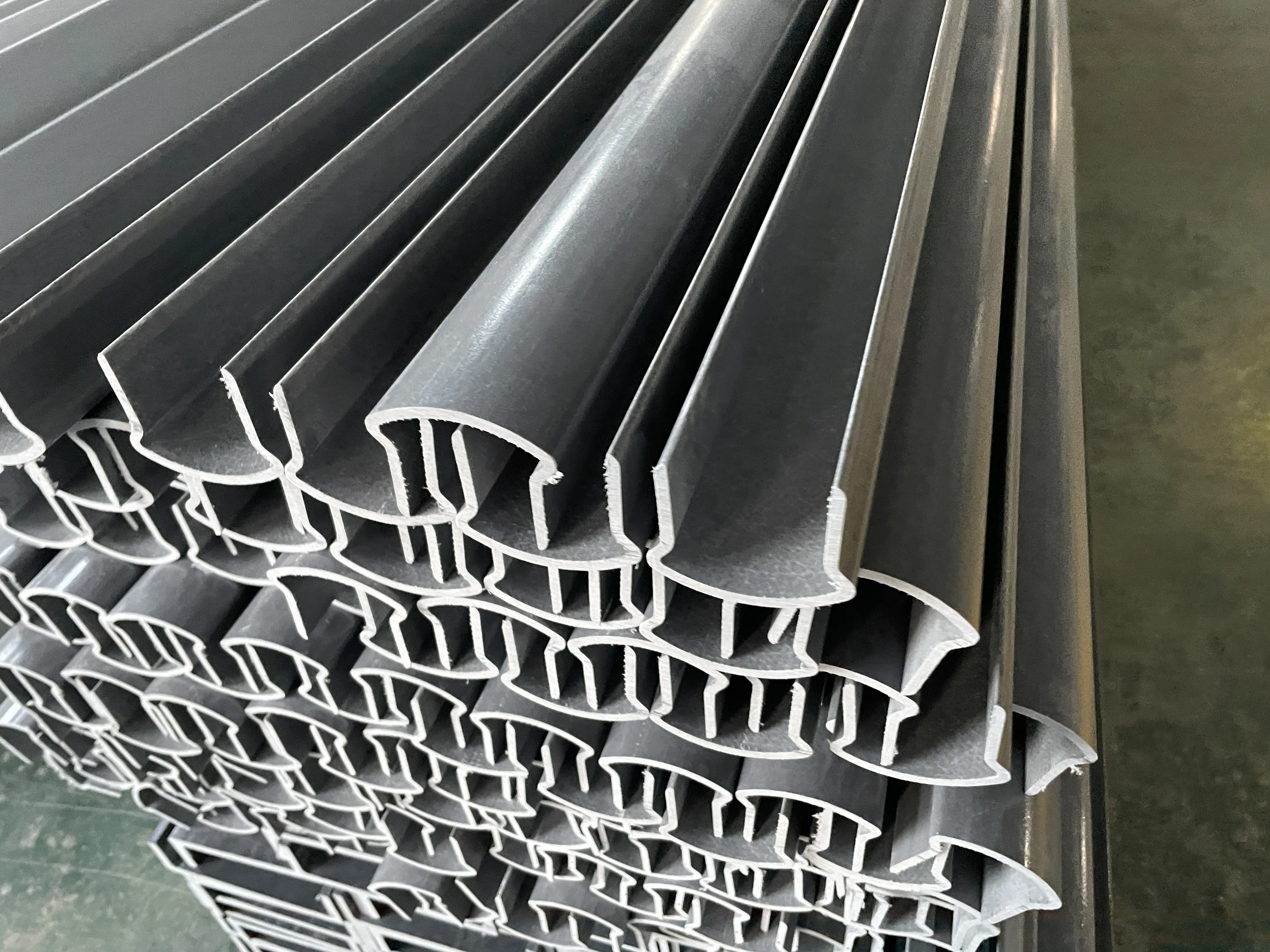

pigment titanium dioxide factory.  tio2 concrete factory. During this stage, the TiO2-infused concrete gains strength and stability. The curing conditions, including temperature and humidity, are closely monitored to optimize the properties of the final product.

tio2 concrete factory. During this stage, the TiO2-infused concrete gains strength and stability. The curing conditions, including temperature and humidity, are closely monitored to optimize the properties of the final product.

As a food additive, titanium dioxide and its nanoparticles in particular have been associated with DNA damage and cell mutations, which in turn, have potential to cause cancer. When used as a food coloring, it is known as E171.

Neurotoxicity

It is suitable as an alternative to titanium dioxide when higher acid resistance is required, such as in adhesive joints and sealants.

Main products are titanium dioxide LR-982, titanium dioxide LR-108, titanium dioxide LR-996, LR-895 and other products.

RRAM and the New Computing Paradigm

Another factor to consider is customer service and after-sales support. With suppliers located in different countries, clear communication and reliable support are critical. Manufacturers who provide comprehensive technical support and guidance on their products can help clients navigate challenges that may arise during production.

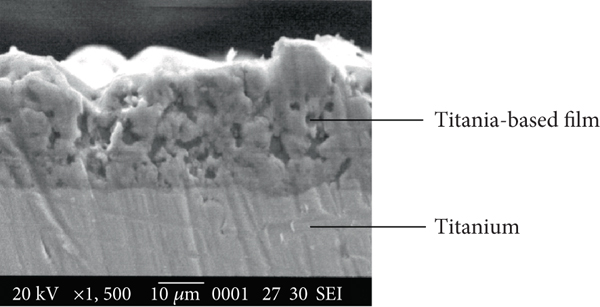

Titanium dioxide is an insoluble mineral, meaning it cannot dissolve in water. Known for its bright, white pigment, manufacturers use titanium dioxide in many different capacities, including in cosmetics, foods, and drugs.

For his part, Kaminski argues most of the studies have been in animals, and any effects found were minuscule. He and his team also contested some of the findings in a 2019 study that found no evidence of increased inflammation or changes in the GI tract.

Lithopone manufacturer: Application areas

Oxygen Deficiency and Resistive Switching Mechanisms

According to the American Chemistry Council, titanium dioxide (TiO2) is an inorganic substance that's used as a white powder in a variety of industrial and consumer goods, including in sunscreen, cosmetics, toothpaste, paint, plastics, food and more.