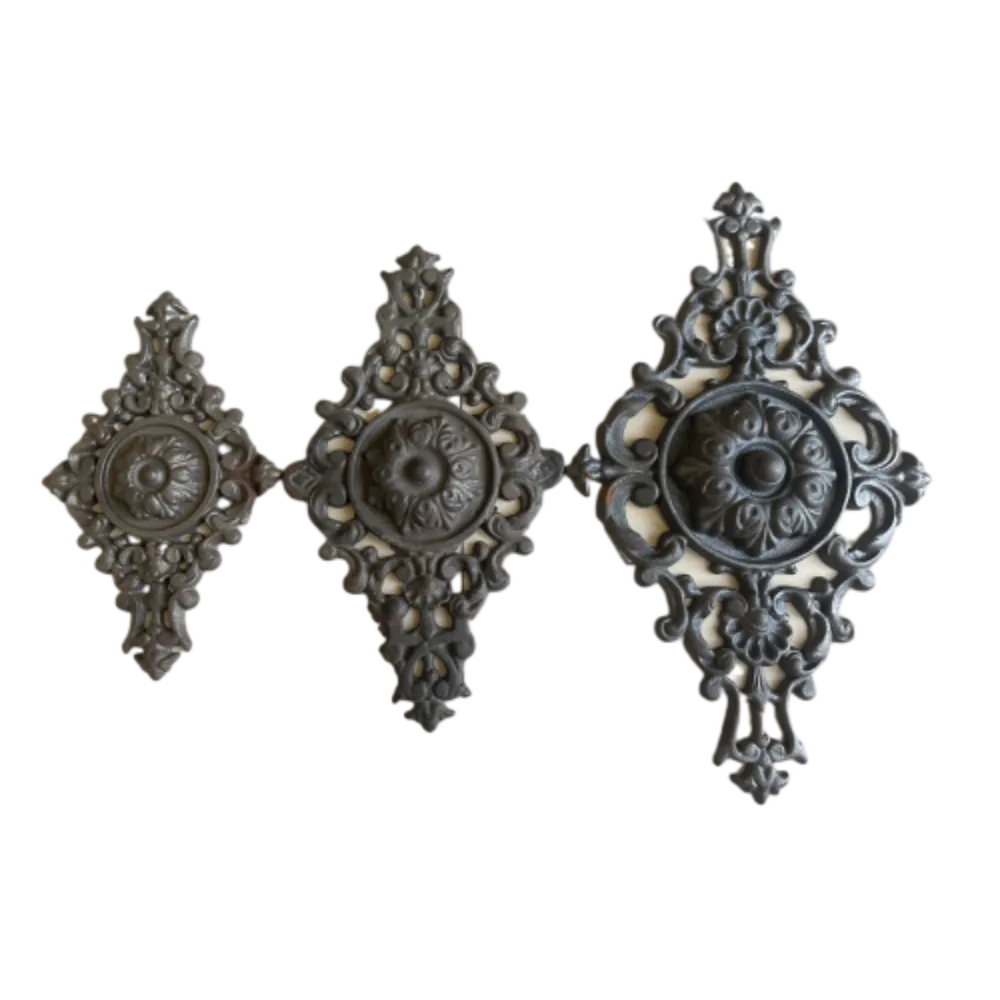

cast iron panels for railing. Unlike wood or other materials, cast iron does not require frequent staining or sealing to maintain its appearance. A simple cleaning with soap and water is typically all that is needed to keep these panels looking their best.

cast iron panels for railing. Unlike wood or other materials, cast iron does not require frequent staining or sealing to maintain its appearance. A simple cleaning with soap and water is typically all that is needed to keep these panels looking their best. To prolong the life of aluminum sliding door rollers and ensure optimal performance, regular maintenance is essential. Here are some best practices

Aluminium Profiles Quality Test │ Flatness

Heavier doors might require larger, sturdier wheels for optimal support and movement Heavier doors might require larger, sturdier wheels for optimal support and movement

Heavier doors might require larger, sturdier wheels for optimal support and movement Heavier doors might require larger, sturdier wheels for optimal support and movement adjusting sliding door wheels.

adjusting sliding door wheels. One of the key benefits of using a stainless steel gate lock box is the high level of security they provide. Made from strong and resistant materials, these lock boxes are extremely difficult to tamper with, making it nearly impossible for intruders to break into your property. This added security gives you peace of mind knowing that your property and belongings are safe and secure.

There are differences in their chemical composition, but the primary difference between cast iron and wrought iron is in how they’re produced: cast iron is iron that’s been melted, poured into a mold (i.e. a “cast”), and allowed to solidify into its current shape. Wrought iron, on the other hand, is iron that’s been heated and hammered with tools (i.e. “wrought,” the archaic past tense of “work”) to form it into a precise shape.

2. Metal Iron and aluminum gates are durable and provide excellent security. They can withstand harsh weather conditions and require minimal upkeep. However, they may need periodic painting or sealing to prevent rust.

Profilati Alluminio manufactures and ships worldwide – thus in the U.S. too – various types of aluminum extrusions also with extremely small dimensional tolerances: among them, aluminum window extrusion profiles.

Your structural design determines the type of profiles you will select.

Another benefit of aluminum window extrusion profiles is their sleek and modern look. The slim frames of aluminum windows allow for larger panes of glass, maximizing natural light and views from inside the home. Additionally, aluminum frames can be designed with clean lines and sharp angles, creating a contemporary and minimalist aesthetic that is popular in modern architecture.

aluminum window extrusion profiles

In addition to their practical uses, things can also hold sentimental value for us

. We often form emotional attachments to objects that remind us of important moments or people in our lives. Whether it's a cherished piece of jewelry that was passed down from a loved one or a childhood toy that brings back happy memories, these things hold a special place in our hearts and can bring us comfort and joy.hings

Your home may benefit from adding the flair that a wrought iron fence can provide. Because there are so many styles to choose from, it is simple to create a personalized appearance and feel that is entirely your own, in addition to one that will make you more secure while adding value to your home.

Ultimately, the question “Are there more doors or wheels?” may not have a definitive answer. It opens up discussions about consumption, manufacturing, cultural significance, and the impact of design in our daily lives. What is clear is that both play crucial roles in shaping our environment and experiences.