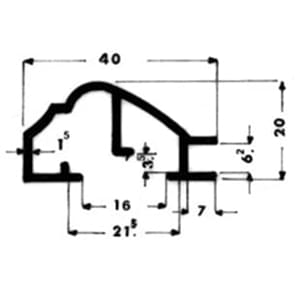

You must also consider the material thickness of the specific aluminum profiles you are purchasing.

It is the ideal method to fix aluminum profiles while allowing movement. You can attain this in many ways by using two cylindrical features.

Links

These differing methods result in materials that, while they’re both iron, have significant differences in cost, strength, hardness, malleability, and chemical composition.

Conclusion Choosing the Right Tap for the Job

This is regarded as the easiest and fastest way to fix different aluminum profiles.

In addition to their strength, wrought iron rail parts are also highly durable. Unlike other materials that may rust, warp, or deteriorate over time, wrought iron is known for its resistance to corrosion and weathering. This makes it a low-maintenance option for railings, especially in outdoor settings where exposure to the elements is a concern. With proper care and maintenance, wrought iron rail parts can last for decades, providing long-term value for property owners.

Sliding doors typically operate on rollers that sit on a track. These rollers help the door glide smoothly open and shut. Misalignment can occur for several reasons, including age, repeated use, or an accumulation of dirt and debris. Before you begin adjusting the rollers, it's essential to identify the type of sliding door you have. Most sliding doors will either have adjustable rollers that can be accessed easily or those that may require some disassembly.

The material is ideal for outdoor use. It stands up well to various weather conditions and adds a touch of elegance with its classic designs.

Some runners even have built-in dampening systems to slow down the door's closing speed, ensuring safety and preventing accidental slamming Some runners even have built-in dampening systems to slow down the door's closing speed, ensuring safety and preventing accidental slamming

Some runners even have built-in dampening systems to slow down the door's closing speed, ensuring safety and preventing accidental slamming Some runners even have built-in dampening systems to slow down the door's closing speed, ensuring safety and preventing accidental slamming sliding door runner wheels.

sliding door runner wheels. When we’re designing a custom iron fence or railing, we offer customers the option to add decorative elements made from cast iron to an otherwise wrought iron structure. Those pieces are then welded onto the pickets of the railing. This process can save on costs, since producing intricate decorative designs in wrought iron through hand forging can get expensive.

This insulating layer can take several forms, e.g. ABS, Noryl or PVC. A fourth possibility is polyamide (also known as PA). This is a high quality plastic that is manufactured from benzene in specialised factories. Polyamide shares a number of advantages with aluminium (wear resistance, 100% recyclable, etc.) but also adds some more.

Steel pull handles are available in a wide array of designs, finishes, and sizes, allowing for customization to suit various architectural styles. From sleek, modern designs to more ornate, classic styles, there is a steel pull handle for every aesthetic. Various finishes, including brushed, polished, and powder-coated options, provide further opportunities for customization while also offering additional corrosion resistance. This versatility allows for seamless integration with diverse design themes, whether contemporary, industrial, or traditional.

For applications with certain structural strength requirements, such as large doors and windows. It is better to choose the profile with higher tensile strength, such as: 6063-T6.

cast iron. Its natural rustic finish can be enhanced with various coatings or left to develop a charming weathered look over time. Artists and designers cherish cast iron for its ability to capture fine details and complex patterns, allowing them to create one-of-a-kind pieces that range from the whimsical to the grandiose.

cast iron. Its natural rustic finish can be enhanced with various coatings or left to develop a charming weathered look over time. Artists and designers cherish cast iron for its ability to capture fine details and complex patterns, allowing them to create one-of-a-kind pieces that range from the whimsical to the grandiose. You must also consider the material thickness of the specific aluminum profiles you are purchasing.

It is the ideal method to fix aluminum profiles while allowing movement. You can attain this in many ways by using two cylindrical features.