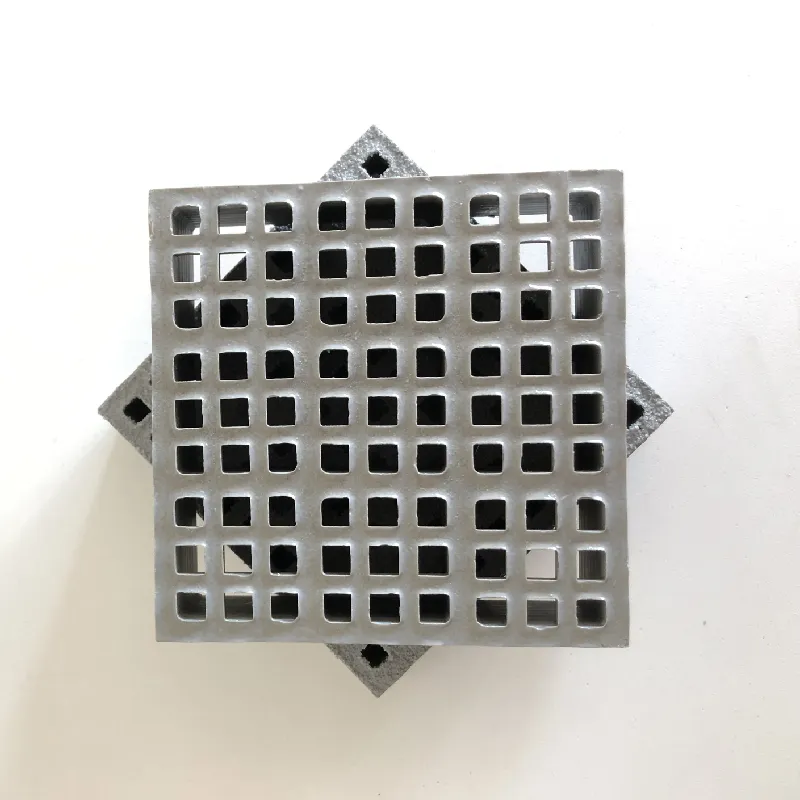

square water tank with cage

-

Anti-slip products come in a wide array of forms, each designed to cater to different needs and environments

. The most popular categories include...

Links

How to Choose the Right Oil Seal

When selecting the oil seal that is right for your machine, it is important that the oil seal be appropriate for the requirements of the usage environment and that it be easily acquired for replacement.

In this month's column, How to select the right oil seal, we conveyed the following points:

1) Oil seal shape and material should be selected based on the housing, substance to be sealed, pressure, rotational speed, total eccentricity, and air-side conditions.

2) Oil seals can show good sealing performance in combination with properly designed shafts and housings.

3) Oil seal performance is affected by not only the type and material of the selected oil seal, but also a variety of other factors, such as operating conditions, total eccentricity, rotational speed, the substance to be sealed, and lubrication conditions. For this reason, diligent care is required in oil seal selection.

Oil Seal Overview

Cassette seals are designed to maximise grease or oil retention and protection against liquid or solid contaminants. These seals are provided with their own bushings in which dirt is kept out and oil/grease kept in by a multi-lip seal.

Start the engine and check for oil leaks round the sump flange. Stop the engine and tighten the mountings.

Check the faces of the head and block for flatness. Alloy heads in particular can distort and then leak.

Proper preparation is crucial for successful oil seal installation. Ensuring that the seal, shaft, and bore are correctly prepared and aligned prevents seal failure, leakage, and premature wear of the components.

Oil Seals 101 – The Ultimate Guide

-40 °C to + 90 °C

The Spark Plug also opened up new possibilities for indie developers, who could use the device to create innovative and immersive experiences that would have been difficult or impossible with traditional controllers The Spark Plug also opened up new possibilities for indie developers, who could use the device to create innovative and immersive experiences that would have been difficult or impossible with traditional controllers

The Spark Plug also opened up new possibilities for indie developers, who could use the device to create innovative and immersive experiences that would have been difficult or impossible with traditional controllers The Spark Plug also opened up new possibilities for indie developers, who could use the device to create innovative and immersive experiences that would have been difficult or impossible with traditional controllers e3 12 spark plug.

e3 12 spark plug.

Wilmink Engine Parts offers a wide range of oil seals for various applications and engines. Poor-quality oil seals can cause problems. Our range offers only quality brands and our specialists will be happy to help you choose the right product for your application. Below, we highlight some of our brands with their catalogues around oil seals.

Car Head Gasket: Essential Component in Engine Sealing

There may be a rubber '0' ring oil seal round the base of the distributor, or a paper gasket under the plate of the securing clamp. Remove either seal, clean away all dirt and oil, and fit the new one.

Despite being a great substitute for more expensive high temperature resistant materials, polyacrylate has a problem of poor water compatibility and cold flexibility.

Oil seals, also known as rotary shaft seals, are a type of gasket used to prevent lubricant leakage and contamination in rotating machinery by creating a barrier between the moving and stationary parts.