galvanized steel water tanks

Links

-

Benefits of Using Flat Bed Sewing Machines

-

-

One of the key advantages of using a double needle coverstitch is its ability to provide a durable seam that won't easily unravel. Unlike standard sewing techniques that can compromise the integrity of the seam when stretched, the coverstitch uses a combination of straight stitching and chain stitching to absorb tension without breaking. This is particularly important in areas of a garment that experience a lot of wear and movement, such as armholes, waistbands, and hems.

-

Conclusion

-

4. Easy Threading and Setup Many heavy-duty models are designed with user-friendly features such as automatic needle threading and easy bobbin winding systems, which simplify the setup process for beginners.

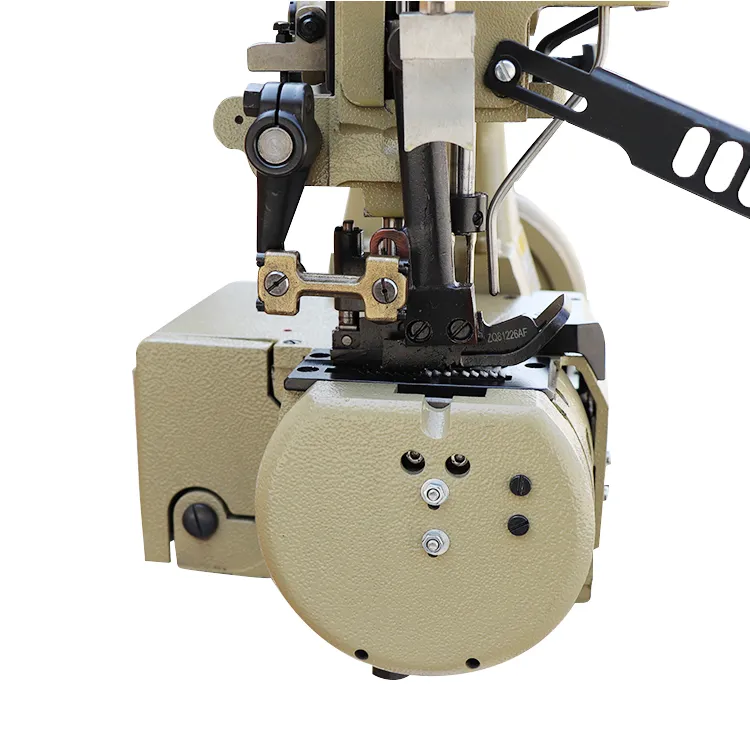

A leather manual sewing machine is specifically designed to handle the unique challenges posed by sewing leather, a material that is thicker and tougher than standard fabrics. While modern electric sewing machines can often struggle with leather, the manual sewing machine is built with specific features that make it more suited for this purpose. It typically includes a walking foot mechanism, which aids in feeding layers of leather through the machine without slipping, ensuring even stitching. The machine also accommodates heavier threads and needles that are necessary for penetrating tough leather hides.