Testing Spark Plug Wires In rubber seal material, its heat resistance (decomposition temperature is greater than 400

Secures stable sealing performance. |

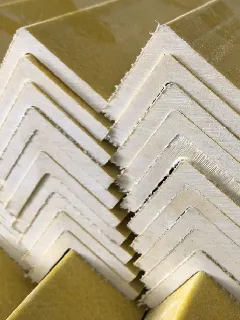

Skeleton oil sealing is a mechanical process that plays a crucial role in the maintenance and longevity of various machinery and equipment. This process involves the use of specialized rubber or synthetic materials to create a barrier between moving parts, preventing oil leakage and ensuring smooth operation. The term skeleton refers to the metal reinforcement within the seal, which provides strength and stability while allowing for flexibility during installation and use. In conclusion, T-shaped gaskets, with their unique design and versatile properties, have carved a niche for themselves in the world of seals and gaskets. Their effectiveness in various industries underscores the importance of tailored solutions in engineering and highlights the ongoing evolution of sealing technology. As industries continue to seek improved performance and safety, the significance of T-shaped gaskets is likely to grow further. Another important feature of rubber flange gaskets is their ease of installation. They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment

They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment rubber flange gasket. This makes them a convenient and efficient sealing solution for maintenance and repair applications. Oil seals are integral components in the operation of machinery, providing a vital barrier between the internal lubricated parts and the external environment. These seals prevent the leakage of oil, which is essential for the proper functioning of the machine's moving parts. With their robust design and durable construction, oil seals ensure long-lasting performance and reduce maintenance costs.

rubber flange gasket. This makes them a convenient and efficient sealing solution for maintenance and repair applications. Oil seals are integral components in the operation of machinery, providing a vital barrier between the internal lubricated parts and the external environment. These seals prevent the leakage of oil, which is essential for the proper functioning of the machine's moving parts. With their robust design and durable construction, oil seals ensure long-lasting performance and reduce maintenance costs. There are several key factors to consider when selecting the right oil seal to best protect your application.

First, wash your hands before handling the oil seal. This is because dirt on the sealing surface or oil in fingerprints can compromise the integrity of the seal, while small particles can cause wear and tear, damaging the sealing surface and leading to leaks.

Secondly, do not unpack the seal unless you are ready to install it. After opening, the seal face must be cleaned before installing it on the equipment to prevent contamination.

Finally, ensure that your equipment is clean. This is because dirty equipment can affect the effectiveness of the oil seal.

A car oil gasket is a crucial component of any vehicle's engine system. It serves as a seal between the engine block and the oil pan, preventing oil from leaking out and keeping it contained within the engine. Without a properly functioning oil gasket, a car could experience serious issues such as oil leaks, engine overheating, and even engine failure. In conclusion, the auto valve cover gasket is not just a mere accessory; it's a guardian of your engine's health. Its role in sealing, pressure maintenance, and preventing oil leaks cannot be overstated. As such, it's important to understand its importance and ensure its proper care and maintenance. Remember, prevention is always better than cure, especially when it comes to the complex machinery that keeps your vehicle running smoothly. Skeleton oil sealing, also known as oil seal, is a mechanical component used to prevent the leakage of fluids in machinery. It is designed to fit around rotating or moving parts, such as shafts or pistons, to create a barrier that prevents oil, gas, or other fluids from escaping. There is a British Standard laid down for the control of synthetic rubbers. BS 3574 (1989) helps to determine shelf life – for instance, Nitrile (NBR) and Polyacrylic (ACM) are Group ‘B’ rubbers and have a 7-year life, whilst Silicone (VMQ) and Fluoroelastomers (Viton®) are Group ‘C’ rubbers and have a 10-year shelf life. PTFE and Leather do not come into this category but like the others should be kept in the original packing for as long as possible away from direct light, dust, and humidity. Ozone, which can also be produced by battery-driven forklift trucks has a very bad effect on synthetic rubbers. Finally, protect the sealing lip – DO NOT hang the seals on nails, wire etc.

In addition to these standardised types, the following special types are also available:

6 Things about Oil Seals You Need to Know

Geographically, Asia Pacific is expected to dominate the oil seal market during the forecast period, followed by Europe and North America

Rubber type

The primary function of an oil seal is to create a barrier between the rotating or moving parts of a machine and prevent oil or other fluids from leaking out. This helps to ensure that the machinery operates smoothly and efficiently without any loss of lubrication or contamination of the surrounding environment. In addition to preventing leakage, oil seals also help to retain lubricant within the system, extending the life of the equipment.

The material used in oil seals is also important, as it affects the seal's durability and resistance to chemicals and heat

They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment

They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment They can be easily placed between two flanges and compressed to create a secure seal without the need for specialized tools or equipment