Why do I have to install my Oil Seal this way?

Today, traditional oil seals have to compete with a new variant oil seal, which is used in most modern engines.

Additionally, the non-conductive properties of FRP grating make it an excellent choice for industrial facilities where electrical hazards may pose significant risks. Its ability to resist electrical currents enhances safety in environments such as power plants and chemical processing facilities, where conventional metal gratings could lead to potentially dangerous situations.

...

Links

They also tend to resist fouling, a common issue in high-performance engines where fuel-rich conditions can cause standard plugs to fail They also tend to resist fouling, a common issue in high-performance engines where fuel-rich conditions can cause standard plugs to fail

They also tend to resist fouling, a common issue in high-performance engines where fuel-rich conditions can cause standard plugs to fail They also tend to resist fouling, a common issue in high-performance engines where fuel-rich conditions can cause standard plugs to fail performance spark plugs.

performance spark plugs. ■Rust and corrosion inhibitors: Your engine’s internal parts can rust and corrode when exposed to acids and moisture. These additives create a protective film over your engine’s internal parts to help prevent such damage.

When there is a need for rebuilding a cylinder and pump instead of building a new one.

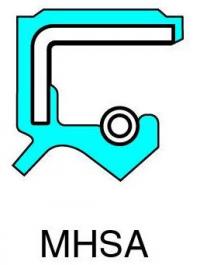

Unthinkable in the list of seals are oil seals, which provide a seal against splashing oil. The most important oil seals are used for rotating shafts and valve stem seals. Oil seals are intentionally never completely sealed to lubricate the seals and prevent wear.

The hardness of the shaft determines how long the seal will last. A shaft should have a Rockwell hardness of 30 or more. It prevents the seal from getting damaged when it’s exposed to abrasive agents.

The 38x52x7 oil seal is a popular size that is used in a variety of applications

. It is commonly used in automotive engines, industrial gearboxes, and hydraulic systems. The seal is designed to withstand the high speeds and temperatures that are common in these types of machinery, and it provides reliable protection against oil leakage.