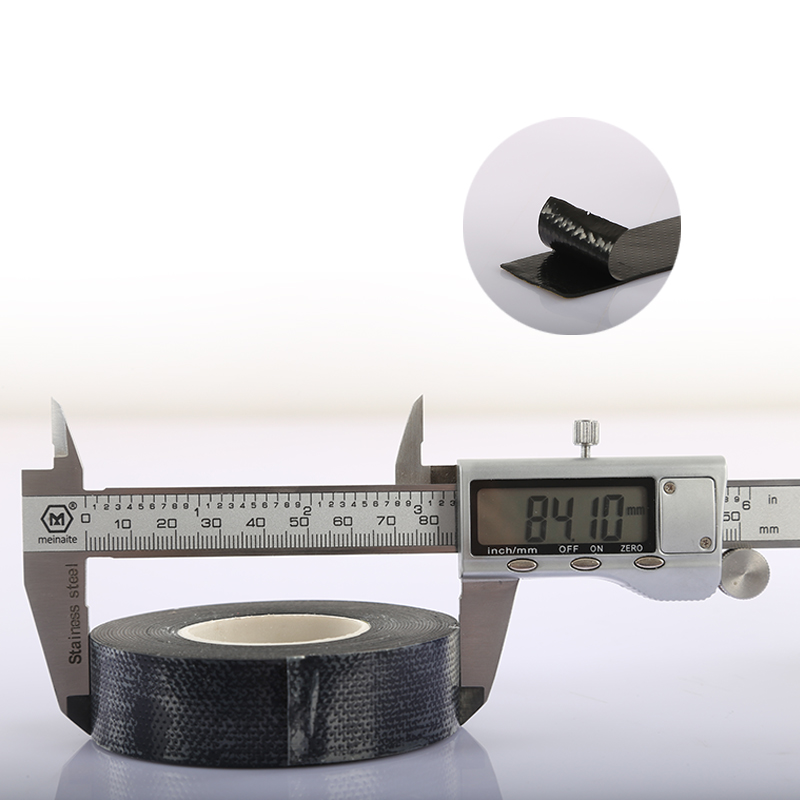

Its non-adhesive nature ensures it won't leave any residue on the wires or components it covers, reducing the risk of electrical shorts or damage Its non-adhesive nature ensures it won't leave any residue on the wires or components it covers, reducing the risk of electrical shorts or damage

Its non-adhesive nature ensures it won't leave any residue on the wires or components it covers, reducing the risk of electrical shorts or damage Its non-adhesive nature ensures it won't leave any residue on the wires or components it covers, reducing the risk of electrical shorts or damage self bonding electrical tape. It also provides excellent electrical insulation, preventing accidental contact with live circuits, and can even be used as a protective layer against electromagnetic interference (EMI) and radio frequency interference (RFI).

self bonding electrical tape. It also provides excellent electrical insulation, preventing accidental contact with live circuits, and can even be used as a protective layer against electromagnetic interference (EMI) and radio frequency interference (RFI). PVC electrical tape and vinyl electrical tape are the two main types of cold-weather tape used for insulating wiring. The conditions in which they will be used may dictate which type you use as follows:

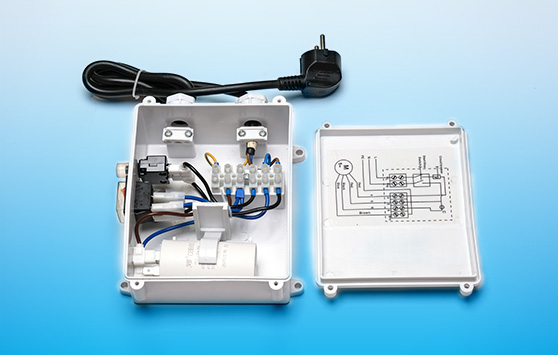

Understanding the Control Box: A Comprehensive Guide

In summary, temporary floor marking tape serves as an essential tool for enhancing safety, promoting organization, and improving efficiency in a wide range of environments. Its user-friendly nature, combined with its versatility, makes it an invaluable asset for businesses and individuals alike. By implementing this simple solution, organizations can foster a safer and more organized atmosphere that ultimately contributes to greater productivity and well-being. Whether in a bustling warehouse or a busy retail store, the impact of temporary floor marking tape is undeniable and worth considering for anyone looking to improve their operational effectiveness.

The various colors available make polyethylene film tapes useful for color coding. Many of products are available in up to seven colors, in addition to clear. Whether you need polyethylene tape or one of the many other kinds of tape in various sizes, colors, and thicknesses, you can find it.

Moreover, the tape’s durable material can resist the wear and tear from the constant vibrations experienced within a running engine Moreover, the tape’s durable material can resist the wear and tear from the constant vibrations experienced within a running engine

Moreover, the tape’s durable material can resist the wear and tear from the constant vibrations experienced within a running engine Moreover, the tape’s durable material can resist the wear and tear from the constant vibrations experienced within a running engine automotive wire harness wrapping tape.

automotive wire harness wrapping tape.

When you own a home with a well, problems can arise unexpectedly.

Butyl rubber based tapes have excellent UV and aging resistance but lower mechanical strength. These tapes are used in foam tape applications and construction and plumbing applications such as pipe joints.

Advantages of Polyimide:

Additionally, the product’s durability cannot be overstated. Flex Tape is designed to withstand extreme temperatures, making it suitable for use in both hot and cold environments. This resilience ensures that repairs made with Flex Tape will endure the test of time, providing long-lasting solutions rather than temporary fixes. Plus, its resistance to UV rays means it won’t deteriorate or discolor when exposed to sunlight, further extending its life.

Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications

Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications Its ability to form a tight seal against water ingress makes it particularly valuable in marine and offshore applications