grp water tank

Links

Foam inhibitors: This additive does exactly what it sounds like. Foam inhibitors keep motor oil from forming foam and bubbles. If foam and bubbles were to form, the oil would be unable to coat the important parts of the engine and keep it cool.

In hydraulic systems, oil seals are used to prevent the leakage of hydraulic fluid from the hydraulic cylinders and valves, which can cause a loss of hydraulic pressure and efficiency In hydraulic systems, oil seals are used to prevent the leakage of hydraulic fluid from the hydraulic cylinders and valves, which can cause a loss of hydraulic pressure and efficiency

In hydraulic systems, oil seals are used to prevent the leakage of hydraulic fluid from the hydraulic cylinders and valves, which can cause a loss of hydraulic pressure and efficiency In hydraulic systems, oil seals are used to prevent the leakage of hydraulic fluid from the hydraulic cylinders and valves, which can cause a loss of hydraulic pressure and efficiency mechanical oil seal.

mechanical oil seal.

⑧

The oil seal manufacturing industry continues to witness innovations aimed at enhancing the performance and reliability of seals. Advancements in material science, seal design, and manufacturing processes have led to the development of seals with improved durability, resistance to extreme conditions, and enhanced sealing capabilities. These innovations contribute to the overall efficiency and longevity of machinery and equipment in diverse industrial sectors.

It is wedge-shaped to be pressed against the shaft surface and makes contact with the shaft to ensure sufficient sealing performance and suitability for operation at high peripheral speed.

The Ultimate Guide to Oil Seals

Figure 7: Oil seals for steel production equipment (rolling mill)

Aerospace industry NBR oil seals are used in aircraft engines, landing gear systems, and hydraulic systems Aerospace industry NBR oil seals are used in aircraft engines, landing gear systems, and hydraulic systems

Aerospace industry NBR oil seals are used in aircraft engines, landing gear systems, and hydraulic systems Aerospace industry NBR oil seals are used in aircraft engines, landing gear systems, and hydraulic systems nbr oil seal.

nbr oil seal. Look at the end of the sump. If you cannot see clearly whether you need to remove the engine, consult a car service manual or dealer.

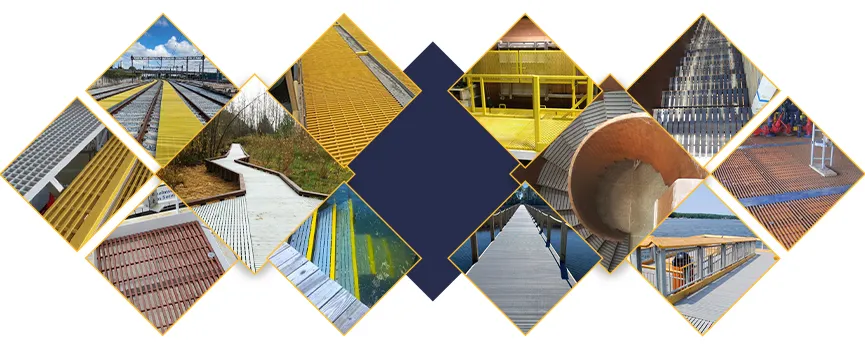

Variety of Oil Seals

Polyacrylate

Better heat, oil and chemical resistance than NBR

It is recommended for use in oil which contains load bearing additives such as EP gear oils

Viton®

High level of chemical resistance

High temperature resistance

Choose a seal that has the appropriate dimension needed for your application. The seal should properly fit the space between the stationary and rotating parts.

contaminated with moisture or any other particle. But the same oil will only last for a month at 212 degrees Fahrenheit if it’s contaminated with little water. This is why the function of an oil seal is very evident whenever it’s used.

Most standard oil seals have to comply with the DIN 3760 and ISO 6194 standards. Different standard types of oil seals are available that comply with these requirements.

There are a variety of oil seals used in a variety of applications to help close the space between a stationary and a moving part. By closing the space it prevents any lubricants from escaping. Additionally, oil seals help create a seal that prevents any contaminants from entering machinery which can cause a host of problems. Mechanical equipment and machinery require different size or type oil seals to ensure that there is a superior and precise seal. Because oil seals help reduce contamination or mixing of materials it prolongs the life of machinery and helps ensure a more reliable performance.