frp piles

Links

- Perhaps most importantly, high-quality marine spark plug wires contribute to improved fuel efficiency. By ensuring that the spark plugs receive a consistent and powerful spark, these wires help to maximize the combustion process, resulting in more efficient engine operation and reduced fuel consumption. This not only saves money on fuel costs but also helps to reduce emissions and promote a cleaner environment.

These fillers, such as carbon black or glass fibers, enhance the physical properties of the rubber These fillers, such as carbon black or glass fibers, enhance the physical properties of the rubber

These fillers, such as carbon black or glass fibers, enhance the physical properties of the rubber These fillers, such as carbon black or glass fibers, enhance the physical properties of the rubber 20 30 7 oil seal. They improve the seal's, heat resistance, and chemical stability, thereby optimizing its performance in harsh environments.

20 30 7 oil seal. They improve the seal's, heat resistance, and chemical stability, thereby optimizing its performance in harsh environments. Another critical factor to consider is the type of seal most suitable for particular machinery. When selecting your mechanical sealing solution, assess your machine’s shaft speed, temperature, pressure, environment, and the medium coming into contact with the seal during an operation. These factors help determine the color, size, sealing element, lip material to choose from, and if it can be sealed out or sealed in.

Unthinkable in the list of seals are oil seals, which provide a seal against splashing oil. The most important oil seals are used for rotating shafts and valve stem seals. Oil seals are intentionally never completely sealed to lubricate the seals and prevent wear.

Ultimately, oil seals are devices that help to exclude dust and dirt, etc., while at all times retaining the lubricant in the piece of equipment.

spark plug 794 055a. A properly functioning spark plug ensures that the air-fuel mixture is burned efficiently, maximizing the power output of the engine. This leads to better fuel economy and lower emissions, contributing to a cleaner and more environmentally friendly driving experience.

mm

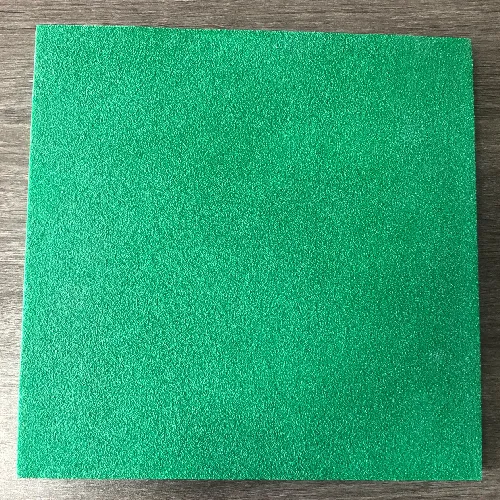

Oil seals for steel production equipment

2.0 tsi valve cover gasket.0% TSI engine running smoothly. Signs of a failing gasket include oil leaks around the valve cover, a burning smell coming from the engine, or a drop in oil pressure. If any of these symptoms are present, it is crucial to replace the gasket as soon as possible to prevent further damage to the engine.

They contribute to environmental stewardship by preventing oil spills that could contaminate ecosystems They contribute to environmental stewardship by preventing oil spills that could contaminate ecosystems

They contribute to environmental stewardship by preventing oil spills that could contaminate ecosystems They contribute to environmental stewardship by preventing oil spills that could contaminate ecosystems