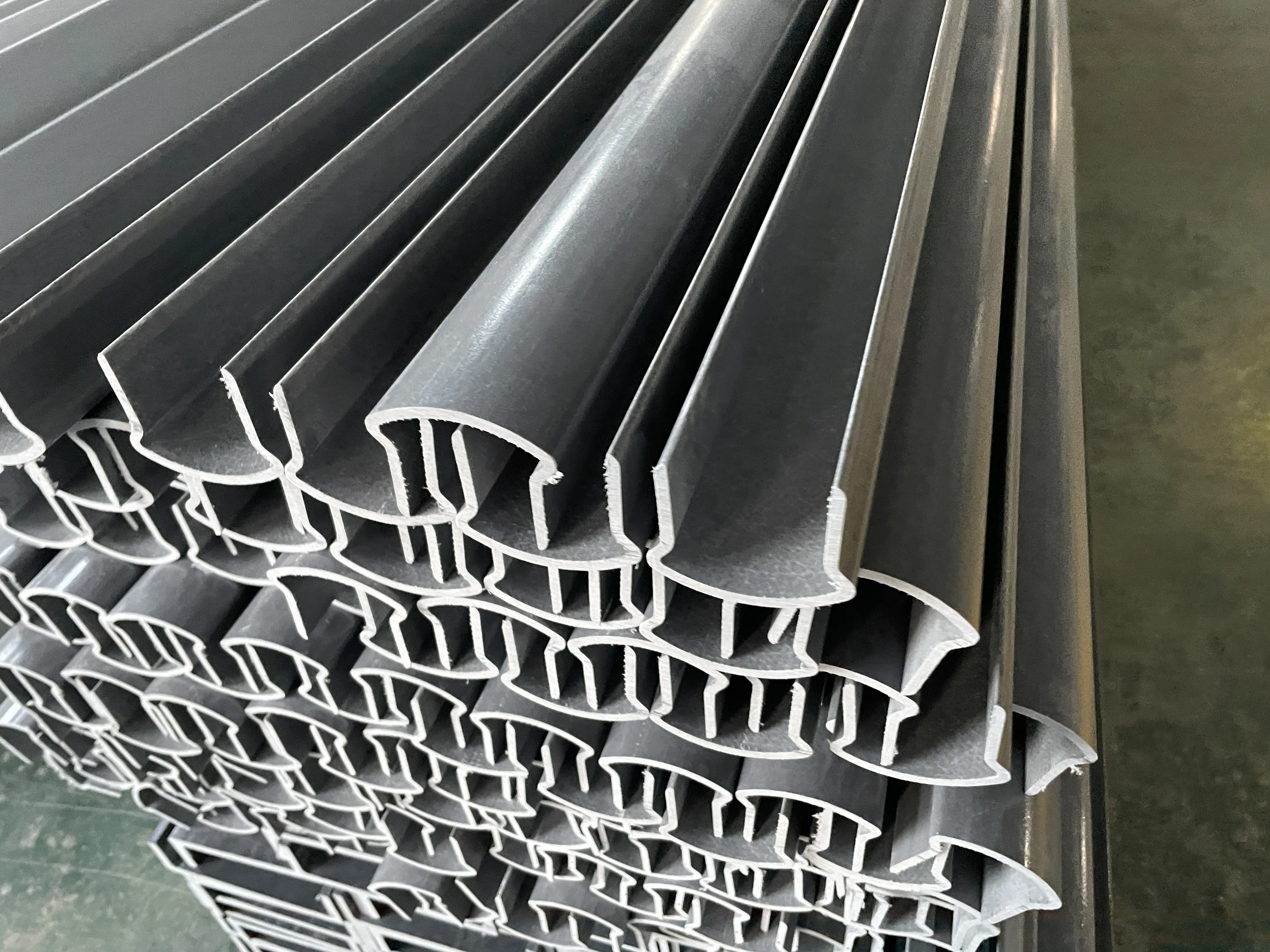

grating frp

-

One of the most critical stages of water treatment is disinfection. This step is vital for killing pathogenic microorganisms that can cause diseases. Common disinfection methods include chlorination, where chlorine or chlorine compounds are added to kill bacteria and viruses, and UV radiation, which uses ultraviolet light to destroy harmful pathogens. The effectiveness of these methods is crucial in ensuring that treated water meets health standards set by regulatory bodies.

...

Links

-

Understanding the Importance of Impeller Wear Ring Maintenance

-

Understanding the components of the wet end of a slurry pump is vital for anyone involved in industries that rely on such equipment. Proper maintenance and selection of high-quality parts can significantly enhance the efficiency and lifespan of a slurry pump, reducing operational costs and minimizing downtime. By focusing on the critical wet end parts—impeller, casing, wear plates, flanges, and the shaft assembly—operators can ensure their pumps perform reliably in challenging environments.

-

-

Simplified Installation with Vertical Inline Centrifugal Pumps

-

One of the primary advantages of purchasing wholesale slurry pumps is cost efficiency. When companies buy in bulk, they can take advantage of reduced prices, resulting in significant savings. This is especially beneficial for large-scale projects where multiple pumps are required. In addition, wholesale suppliers typically offer a wide range of models and specifications, allowing businesses to choose the most appropriate pump according to their unique needs. This capability ensures that operations can run smoothly and efficiently without significant downtime caused by equipment failure.

-

The Compact Footprint of Vertical Multistage Centrifugal Pumps

-

-

Propeller pumps are a crucial element in the field of fluid dynamics, primarily utilized for their efficiency in moving large volumes of fluids. These pumps operate on a simple principle they use a rotating propeller to impart energy to the liquid, creating a flow that can be directed to various applications. This article explores the various uses and advantages of propeller pumps.

-

Comparing Vertical and Horizontal Pumps: Key Considerations

-

Understanding the components of the wet end of a slurry pump is vital for anyone involved in industries that rely on such equipment. Proper maintenance and selection of high-quality parts can significantly enhance the efficiency and lifespan of a slurry pump, reducing operational costs and minimizing downtime. By focusing on the critical wet end parts—impeller, casing, wear plates, flanges, and the shaft assembly—operators can ensure their pumps perform reliably in challenging environments.

-

These flanges serve as the connection points for the inlet and outlet of the pump. Proper alignment and sealing of these flanges are vital to ensure the efficient operation of the pump and to prevent leaks. They can vary in size and shape depending on the specific application and the system's design.

-

-

Understanding Slurry Pump Wet End Parts A Comprehensive Overview

-

Wear Factors: Impellers are subject to high levels of wear due to the abrasive nature of slurries.Materials: Common materials for impellers include high-chrome alloys, natural rubber, and polyurethane.

-

Efficiency Testing for AH Slurry Pump Parts

-

SPR slurry pumps are specifically designed for handling slurry in applications where high liquid levels are a concern. These pumps are engineered to operate efficiently in environments where the pump must remain submerged for extended periods. The vertical design of SPR slurry pumps allows them to function effectively in deep pits and sumps, where other pump types might struggle. By optimizing the design to handle high liquid levels, SPR slurry pumps provide reliable performance in challenging conditions, ensuring that slurry is effectively managed and transported, even in the most demanding deep pit applications.

-

-

-

Enhancing Durability with High Pressure Vertical Pumps

-

Wear Factors: Continuous contact with the slurry and seals can cause wear on the shaft sleeves.

-

7. Expeller and Expeller Rings

-

Selecting the appropriate slurry pump model quickly involves understanding your application's specific requirements and matching them with the pump's capabilities.

-

Establishing a Pump Wet End Replacement Schedule

-

-

-

-

Function: Seals prevent slurry from leaking out of the pump and protect the internal components.

-

-

3. Casing

-

-

b. Selection Software:

-

-

-

The vertical design of slurry pumps offers numerous advantages for deep pit applications, from a compact footprint and ease of installation to enhanced durability and simplified maintenance. Vertical multistage centrifugal pumps are particularly well-suited to these environments, where space constraints, high pressures, and abrasive conditions are common. By focusing on structural engineering and optimizing the design of these pumps, industries can ensure reliable performance and cost-effective operation in even the most challenging deep pit applications.

-

The impeller wear ring is a crucial component in any pumping system, particularly in slurry applications where abrasive materials can cause significant wear. Over time, the wear ring can erode, leading to decreased efficiency and increased energy consumption. To prevent these issues, it’s essential to regularly inspect the wear ring and replace it before it becomes too worn. By monitoring the condition of the impeller wear ring and understanding the specific wear patterns in your system, you can establish an optimal replacement schedule that prevents unexpected failures and maintains pump efficiency.

-

-

Understanding the Role of Propeller Pumps in Various Applications

-

-

Conclusion

-

Function: Liners protect the pump casing from the abrasive action of the slurry.

-

The Role of Casting Slurry Pump Parts in Wear Management

-

- Temperature: Note the operating temperature of the slurry.

-

-

- Reach out to the pump manufacturer’s technical support team for assistance in confirming your selection.

-

-

Wear Factors: Impellers are subject to high levels of wear due to the abrasive nature of slurries.Materials: Common materials for impellers include high-chrome alloys, natural rubber, and polyurethane.

-

-

Materials: Liners are often made from high-chrome alloys, rubber, or other wear-resistant materials.

-

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire