frp vessel for water treatment

Links

PVC electrical tape and vinyl electrical tape are the two main types of cold-weather tape used for insulating wiring. The conditions in which they will be used may dictate which type you use as follows:

rubber car door seal strip. Made from high-quality rubber materials, these seals can withstand extreme temperatures, UV rays, and other environmental factors without losing their shape or flexibility. As a result, they can last for many years before needing to be replaced.

rubber car door seal strip. Made from high-quality rubber materials, these seals can withstand extreme temperatures, UV rays, and other environmental factors without losing their shape or flexibility. As a result, they can last for many years before needing to be replaced. Solvent-rubber based adhesives have better temperature and aging performance but still poor UV resistance. It is used for electrical and foam tapes.

Surface Features

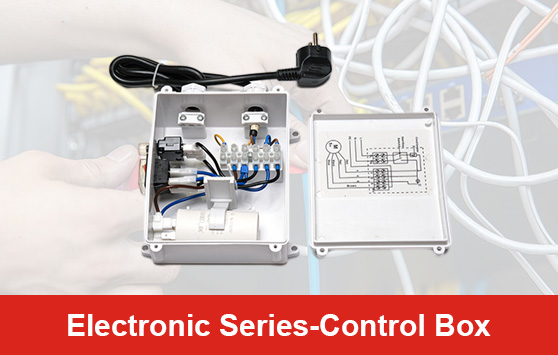

Because control boxes are used for so many different types of equipment, it can be hard to create a basic definition of what they are—but there are definitely some common features. A basic breakdown of the key functions and components of an electrical control box includes:

Control boxes mounted on floors are essentially large-scale boxes specialized for industrial use. They are installed on the floor due to their relatively heavier weight. The heavy weight means that their portability is reduced and it is impractical to mount them on walls.

hazard warning pvc tape. Many industries have strict guidelines on labeling and identifying potential dangers, and using the correct tape is often non-negotiable. By adhering to these standards, organizations not only protect their employees but also demonstrate a commitment to safety, which reflects positively on their reputation and ethical standing.

hazard warning pvc tape. Many industries have strict guidelines on labeling and identifying potential dangers, and using the correct tape is often non-negotiable. By adhering to these standards, organizations not only protect their employees but also demonstrate a commitment to safety, which reflects positively on their reputation and ethical standing.  The tape's adhesive strength and flexibility provide an extra layer of security, preventing unexpected breakages during intense matches The tape's adhesive strength and flexibility provide an extra layer of security, preventing unexpected breakages during intense matches

The tape's adhesive strength and flexibility provide an extra layer of security, preventing unexpected breakages during intense matches The tape's adhesive strength and flexibility provide an extra layer of security, preventing unexpected breakages during intense matches vulcanizing tape.

vulcanizing tape. High voltage self-fusing rubber tape is a non-adhesive tape crafted from a blend of rubber and synthetic materials. Its unique self-fusing properties allow the tape to bond with itself when wrapped around an object, creating a solid, flexible, and waterproof seal. Unlike traditional tapes, the self-fusing nature eliminates the need for adhesive, making it an outstanding choice for high-temperature and high-voltage environments where reliable insulation is crucial.

Edge sealant in Solar PV

Thin (it is only 0.5mm thick)

Alternatives to electrical tape include heat shrink tubing and wire connectors. Heat shrink tubing is usually used for applications with lower gauge wiring, such as smaller electrical circuits, and wire connectors are used at the ends of stripped wires. Other types of adhesive tape should not be used as a substitute for electrical tape as they will not have the thermal efficiency of a dedicated electrical tape and can therefore be unsafe to use in such situations.

Insulation cotton tape is a remarkable product that has garnered significant attention in recent years for its myriad applications and benefits. Constructed primarily from a blend of cotton fibers and insulating materials, this tape is designed to provide excellent thermal resistance, making it an ideal choice for various industries, including automotive, electronics, and construction.

It also has a low flammability rating, which makes it safer to use in buildings and other structures It also has a low flammability rating, which makes it safer to use in buildings and other structures

It also has a low flammability rating, which makes it safer to use in buildings and other structures It also has a low flammability rating, which makes it safer to use in buildings and other structures pvc electrical insulation. Additionally, PVC insulation is relatively inexpensive compared to other insulating materials, making it a cost-effective option for many electrical applications.

pvc electrical insulation. Additionally, PVC insulation is relatively inexpensive compared to other insulating materials, making it a cost-effective option for many electrical applications.  butyl rubber tape suppliers. While it's important to find a supplier who offers competitive prices, you should also ensure that you're not sacrificing quality for cost. Look for suppliers who offer a range of pricing options to suit your budget, and be wary of suppliers who offer extremely low prices, as this may indicate that they're cutting corners on quality.

butyl rubber tape suppliers. While it's important to find a supplier who offers competitive prices, you should also ensure that you're not sacrificing quality for cost. Look for suppliers who offer a range of pricing options to suit your budget, and be wary of suppliers who offer extremely low prices, as this may indicate that they're cutting corners on quality. Before ordering any type of tape, check to see what kind of adhesion it uses. The adhesive side of a tape roll, colloquially called the sticky side, commonly comes in three varieties: acrylic, hot melt, and natural rubber.

It can also protect wires from mechanical damage, like abrasion or chafing, during installation or in harsh operating conditions It can also protect wires from mechanical damage, like abrasion or chafing, during installation or in harsh operating conditions

It can also protect wires from mechanical damage, like abrasion or chafing, during installation or in harsh operating conditions It can also protect wires from mechanical damage, like abrasion or chafing, during installation or in harsh operating conditions electrical pvc insulation tape. Moreover, it's a cost-effective solution compared to other insulation methods, contributing to its widespread use.

electrical pvc insulation tape. Moreover, it's a cost-effective solution compared to other insulation methods, contributing to its widespread use. Price

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel. The naturally occurring rubber harvested from rubber trees is the oldest type of adhesive base and is still in use today in various masking tapes and applications tapes used in the graphics industry. They are inexpensive, can be formulated with predictable adhesion properties, and work well in applications with low shear requirements. These adhesives work well in ambient and low-temperature applications but will struggle when the temperature exceeds about 120°F.

Flex Tape was introduced to the market as a revolutionary product that promised to fix almost anything with just a few simple steps. With its claims of being able to seal leaks, repair cracked surfaces, and hold heavy objects in place, it quickly gained popularity among DIY enthusiasts and homeowners alike.

diall self fusing tape. Its high dielectric strength makes it safe to use on electrical components, providing an extra layer of protection against shorts and sparks. The flexibility of the tape allows for easy wrapping around irregular shapes and surfaces.