grp handrail systems

Links

-

In conclusion, replacing sliding window rollers is a simple and cost-effective way to ensure that your sliding windows continue to function properly. By following the steps outlined above, you can easily replace the rollers on your sliding windows and enjoy smooth and effortless operation once again. With the right replacement rollers and a little bit of effort, your sliding windows can be back to their original condition in no time.

- Another advantage of these panels is their durability. Cast iron is known for its strength and resistance to corrosion, making it a long-lasting material. This means that decorative cast iron panels will continue to look great for years to come, even with regular use.

-

But don’t let the “lightweight” tag fool you – aluminum fences are durable enough for most standard security needs. They are also generally easier to install than other fence types, making them a go-to for DIY enthusiasts.

Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction

Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction sliding roller with steel housing.

sliding roller with steel housing.  Privacy The tall panels of an ornamental cast iron fence offer ample privacy, allowing you to enjoy your outdoor space without being overlooked Privacy The tall panels of an ornamental cast iron fence offer ample privacy, allowing you to enjoy your outdoor space without being overlooked

Privacy The tall panels of an ornamental cast iron fence offer ample privacy, allowing you to enjoy your outdoor space without being overlooked Privacy The tall panels of an ornamental cast iron fence offer ample privacy, allowing you to enjoy your outdoor space without being overlooked ornamental cast iron fence.

ornamental cast iron fence. Support Materials

Glazing: The glass panes that are fitted within the sash and frame. Double-glazed or triple-glazed windows have two or three layers of glazing, respectively, separated by a vacuum or filled with inert gas to improve thermal insulation.

One of the main benefits of using a door sliding roller is its ability to reduce friction and wear on the door track. This not only prolongs the life of the door, but also makes it easier to open and close. In addition, the roller helps to distribute the weight of the door evenly, preventing it from becoming misaligned or uneven.

door sliding roller

When one thinks of architectural beauty and ornate design, rod iron scrolls undoubtedly come to mind. These intricate ironworks, often seen in gates, railings, furniture, and decor, embody a harmonious blend of craftsmanship and artistic flair, transforming ordinary structures into stunning works of art. The charm of rod iron scrolls lies not only in their visual appeal but also in their historical significance and versatility.

A Brief Overview of Wrought Iron Fences

What are the surface treatment processes of aluminum profiles doors and windows

What are the Differences Between Wrought Iron and Cast Iron?

The top-hung opening window provides hinges on both the left and right sides of the frame, with the window handle at the bottom and opening outwards. This window suits more modern styles of aluminium windows as well as window designs with larger glass panels and fewer dividing mullions and transoms.

This project involves a lot of effort, resulting in the end product being rather pricey. Cast iron fencing is produced by melting the iron into a liquid state and then pouring it into molds or castings to give it the desired shape.

Conclusion

At our core, we are dedicated to providing high-quality, visually stunning Ornamental Iron products that not only enhance the visual appeal of your space but also stand the test of time. We take pride in offering a range that combines both form and function, ensuring that our products not only look beautiful but also serve their intended purpose with excellence.

Cast iron ornamental fencing became popular in the early 1900’s due to the cost efficiency of manufacturing the different components of ornamental fencing. Cast iron utilizes molds for the different parts. Steel is melted to extreme temperatures and poured into molds. Once cooled the parts are separated from the molds, cleaned of burns and excess edges and ready for painting. There are several large manufacturers who supply primarily welding sloops who produce the bulk of cast iron ornamental fencing in today’s market.

Finally, various accessories can complement wrought iron fences. These may include decorative elements like arches, trellises, or planters that can enhance the aesthetics of the fence. Lighting fixtures can also be added to improve visibility and create an inviting ambiance during the evening hours.

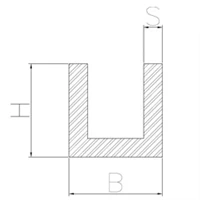

Gate construction is a big one to watch out for too. Unlike a fence panel that is fixed in place and does not move, the gates need to be able to support the weight of the entire leaf as well as any leverage force pressures exerted on them. This is where a proper gate frame comes into play. Many companies will simply weld two posts to the end of a fence section and call it a gate. Functional, but not really all that strong. You will sometimes see cross-bracing on wider gates as a band-aid to poor construction as well. The correct way to make a gate is with a fully boxed and welded gate frame like our Stronghold Iron line. That makes a solid, 3-sided frame that will withstand way more pressure and weight without cracking or deforming. Here is an image showing the U-frame on one of our gates.

Have any questions? Give us a call! With over 40 years of expertise, we’ll ensure that you find the best options for your project.

These aluminium window designs rely on suitable framing and significant expertise by the installer. Only maximum glass sizes determine the sizes possible. Crucially, there are more technical or structural considerations over and above standard window designs, such as wind deflection.

Two are the main types of aluminum window profiles manufactured by Profilati Alluminio, both certified according to the European regulations: