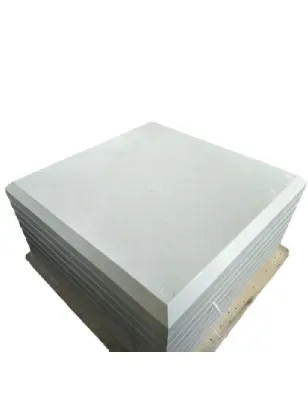

smc panel water tanks

Links

- 1 inch chicken wire fence

- 8 chain link fence cost

- Commercial Chain Link Fence Types and Applications

- Approximate title Madison Park Panel Hog Fence in 4ft x 6ft Dimensions for Sale

- Choosing the Right 125mm Fence Post for Your Garden Project

- 3 inch fence post clamp

- Affordable Options for Single Door Iron Gates and Their Prices

- 5% 20ft Chicken Wire A Closely-Related Topic

- Creating a Beautiful and Functional Garden Fence Design for Your Outdoor Space

- 5ft fence posts

- 1.5 wire coil specifications and applications for various industries and projects

- Durable 32-Inch Chain Link Fence Gate for Enhanced Security and Easy Access in Your Yard

- 14 foot chain link gate

- Affordable Fencing Solutions for Your Outdoor Space and Home Improvement Needs

- double gate fence chain link

- 4.5 x4 5 post caps

- double sided fence panels for concrete posts

- Creating a Garden Gate Using Chicken Wire for Added Security and Aesthetic Appeal

- Best Practices for Supporting and Growing Healthy Sweet Peas in Your Garden

- 4 foot chain link gate

- Choosing the Right 5% Chain Link Fence Gate for Your Outdoor Space

- 6ft high fence panels

- Designing an Efficient Single Sliding Driveway Gate for Enhanced Security and Convenience at Home

- 4-Foot High Chain Link Fencing Solutions for Enhanced Security and Durability

- Creative Solutions for Large Indoor Plant Supports That Enhance Your Home Decor and Greenery

- 6 chain link fencing

- Cổng vườn để bán

- Creating a Sturdy and Effective Tomato Cage with 6 Percent Support for Healthy Plant Growth

- decorative plant supports

- Affordable Fence Panels for Sale _ Cheap Fence Solutions

- 6 square post

- 8 Advantages of Chain Link Fencing

- chicken wire cost

- Durable 4x6 Post Cap Ideal for Outdoor Fencing and Decking Solutions

- Don't attempt to ascend a chain link fence.

- Creative Solutions for Hanging Plant Support Ideas and Tips

- Chicken Wire Solutions for Chipmunks _ Wildlife Control

- Durable 3x6 Feet Fence Panels for Your Outdoor Spaces and Privacy Needs

- 125x125 post caps

- Draining Techniques for Optimal Plant Support and Growth Enhancement

- 5 футовая птушачая сетачка для агароджы і садоў у прыродзе

- Decorative White Fence Ideas for Your Garden Border

- Durable 3x4 Inch Chicken Wire Mesh for Secure Fencing and Garden Protection

- 6-foot tall chain link fence gate for security and accessibility options

- above ground pool security fence

- Creative Vertical Garden Ideas Using Tomato Cages for Space-Saving Planting

- 4 ft chain link fence gate

- climbing plant support

- 2x4 post cap

- Beautiful Chicken Wire Fence for Your Garden and Farm Needs

- cast iron ornamental

- Caster wheels for smooth sliding door operation - a practical solution for easy movement.

- Shijiazhuang TJJ hardware doors and windows

- Aluminum Sliding Wheel A Durable and Versatile Option for Smooth Movement

- Durable metal storage container featuring a secure padlock opening for added protection and convenience

- Iron Works Design - Custom Metal Fabrication & Innovative Design Solutions

- Stainless Steel Gate Handles for Durable and Stylish Home and Garden Applications

- hanging screen door rollers

- Creative Ideas for Middle Decorative Elements to Enhance Your Space and Style

- Shijiazhuang TJJ decorative wrought iron fence panels